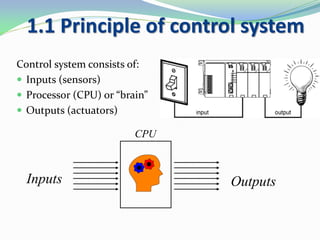

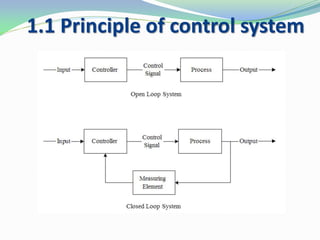

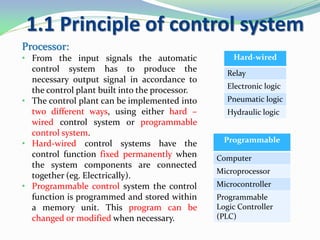

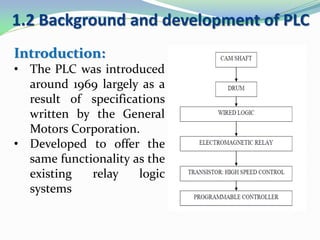

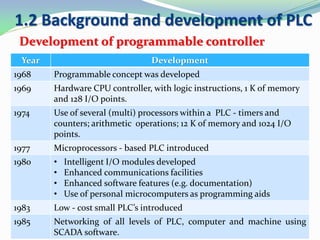

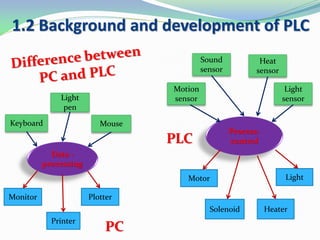

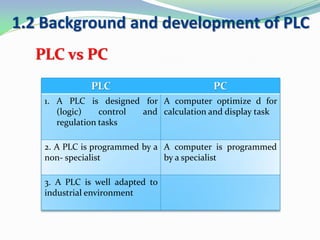

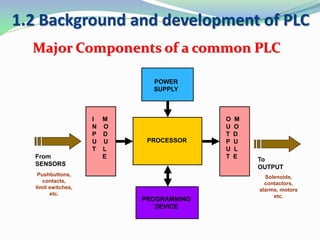

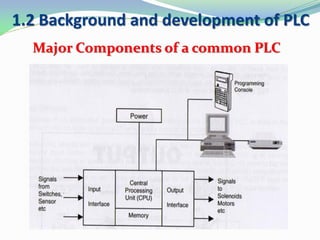

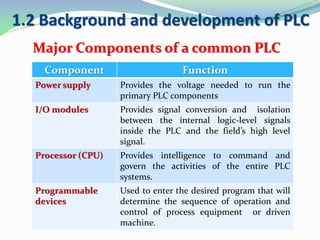

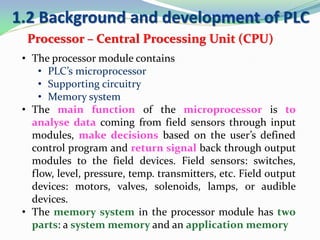

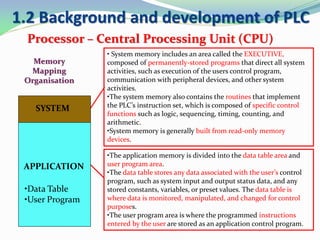

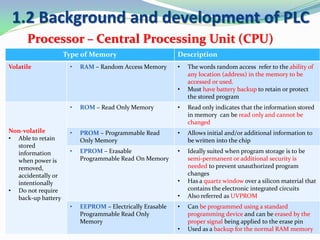

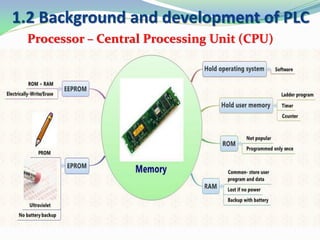

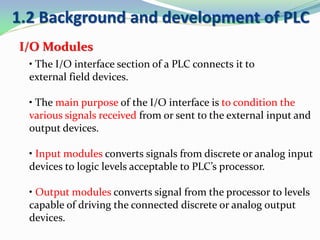

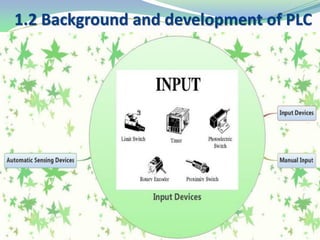

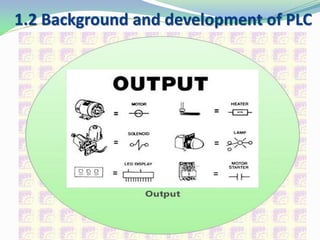

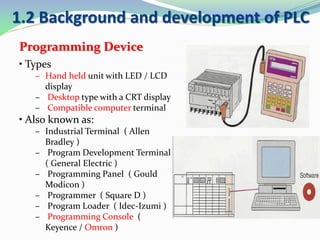

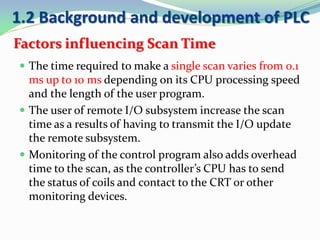

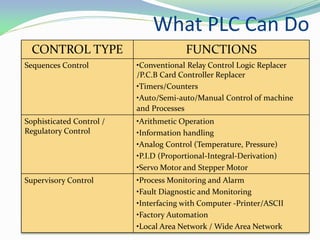

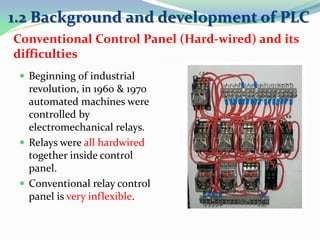

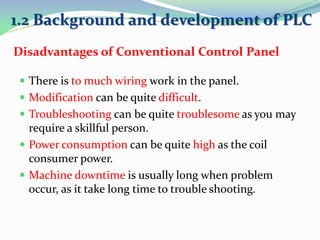

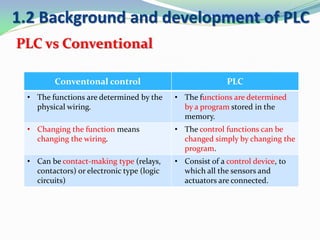

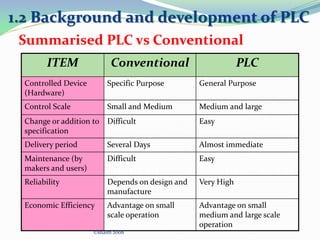

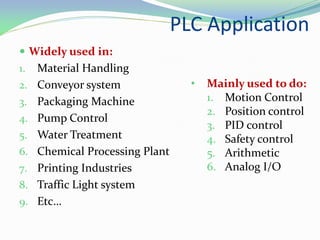

The document discusses programmable logic controllers (PLCs). It begins by explaining the basic principles of a control system, including inputs, a processor, and outputs. It then provides a history of PLC development from the 1960s to present. The main components of a PLC system are described, including the power supply, input/output modules, processor, and programming device. PLCs were created to offer programmable control like relay logic systems and are now widely used in industry.