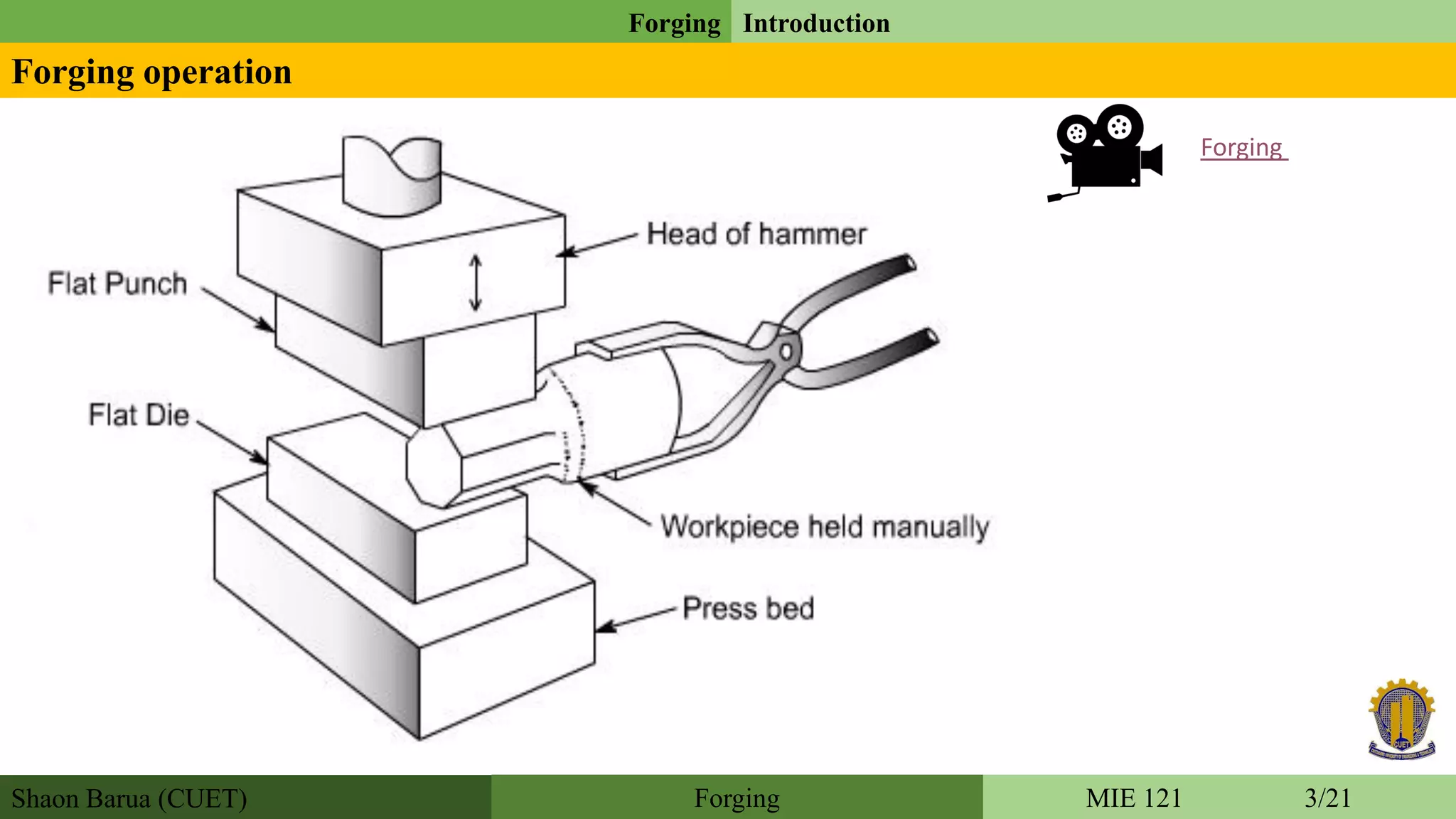

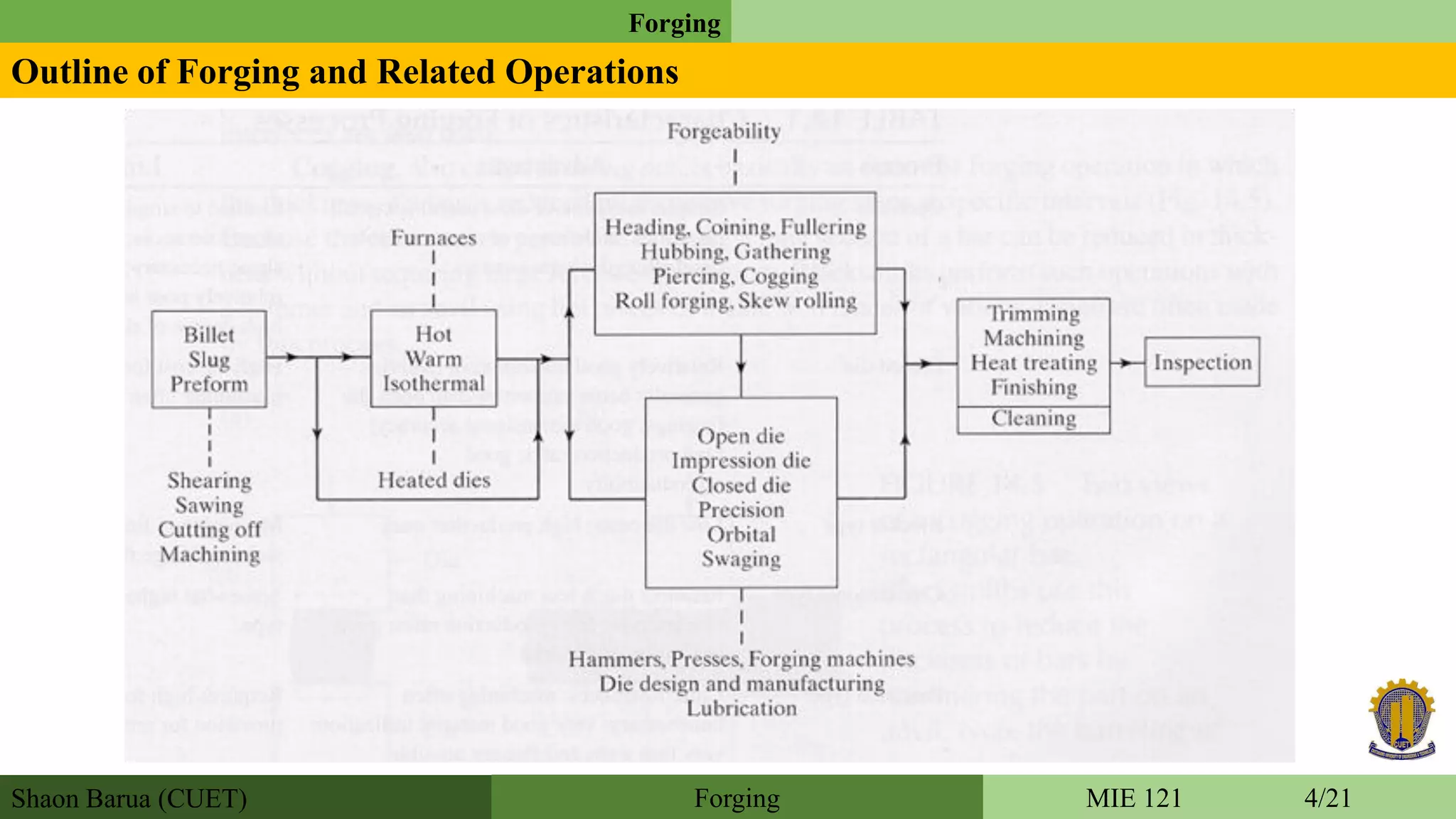

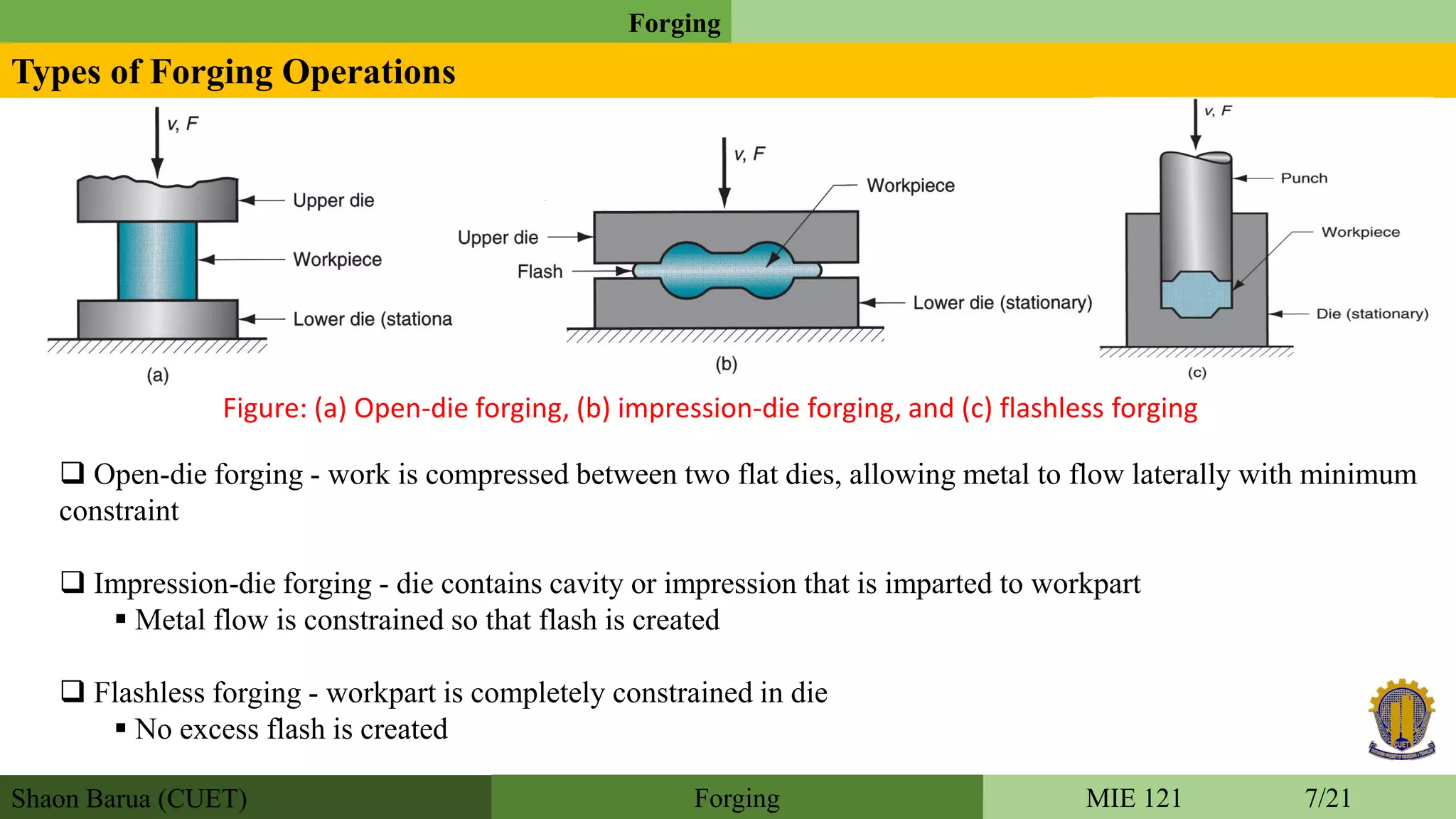

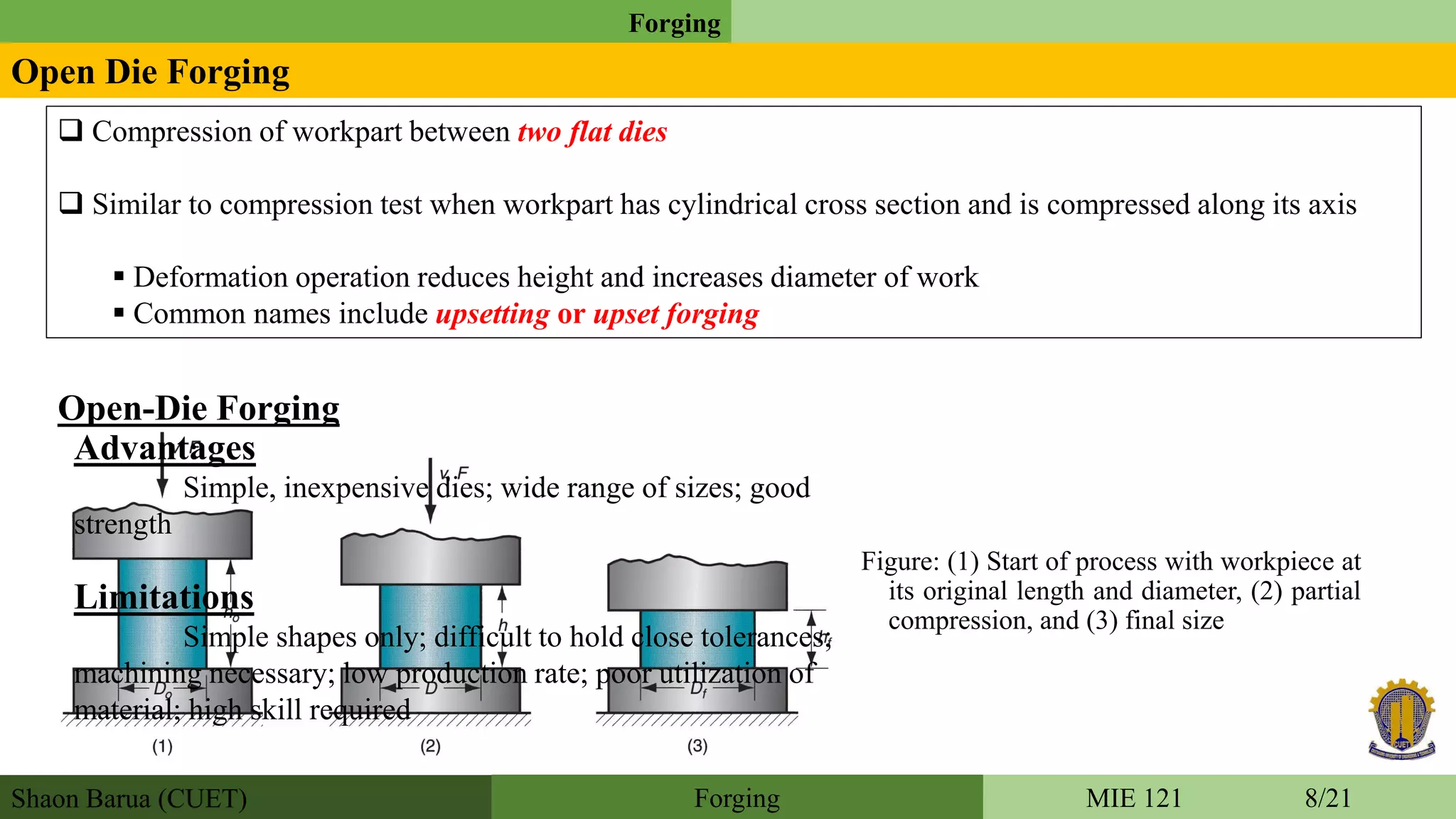

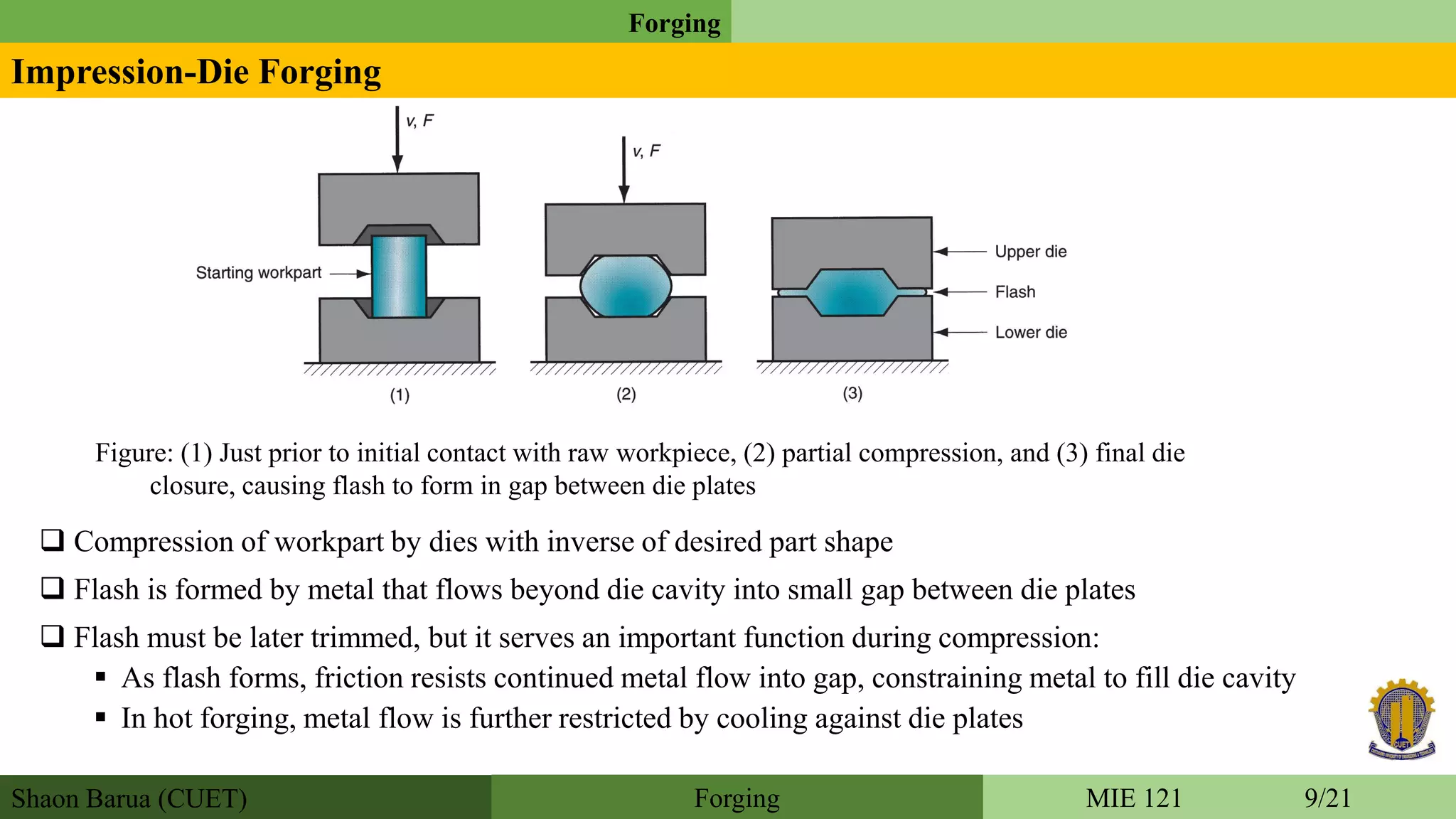

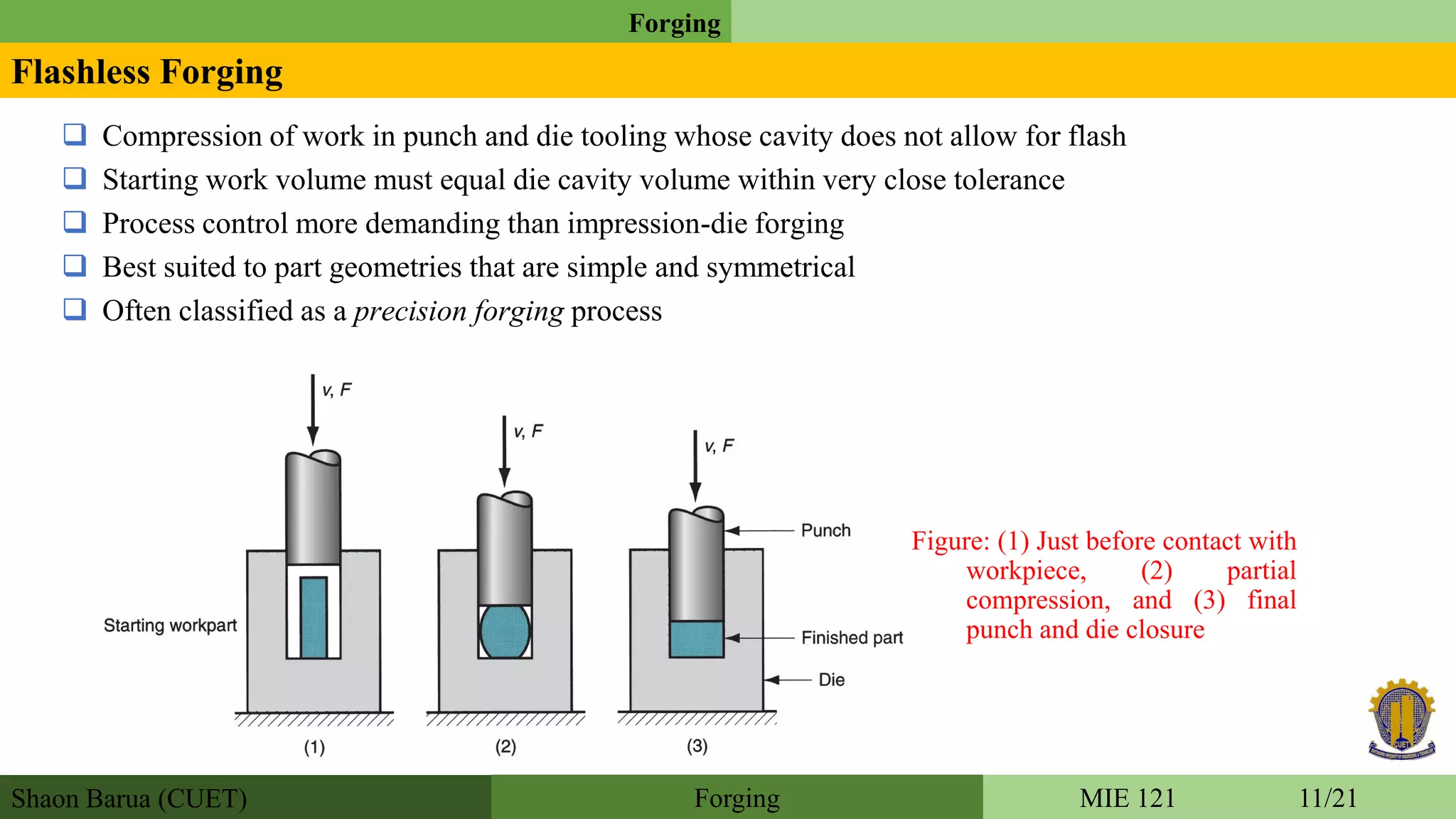

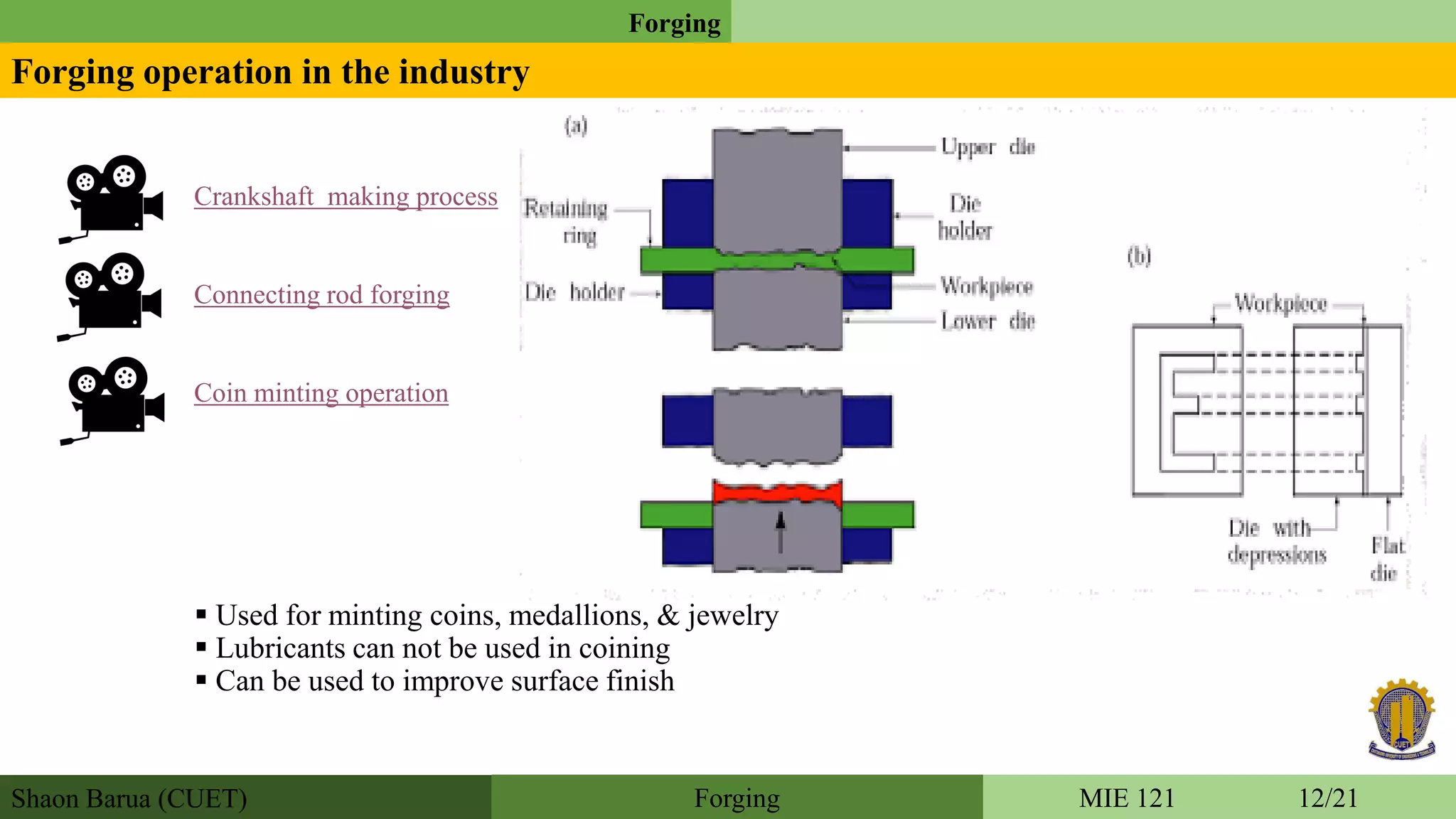

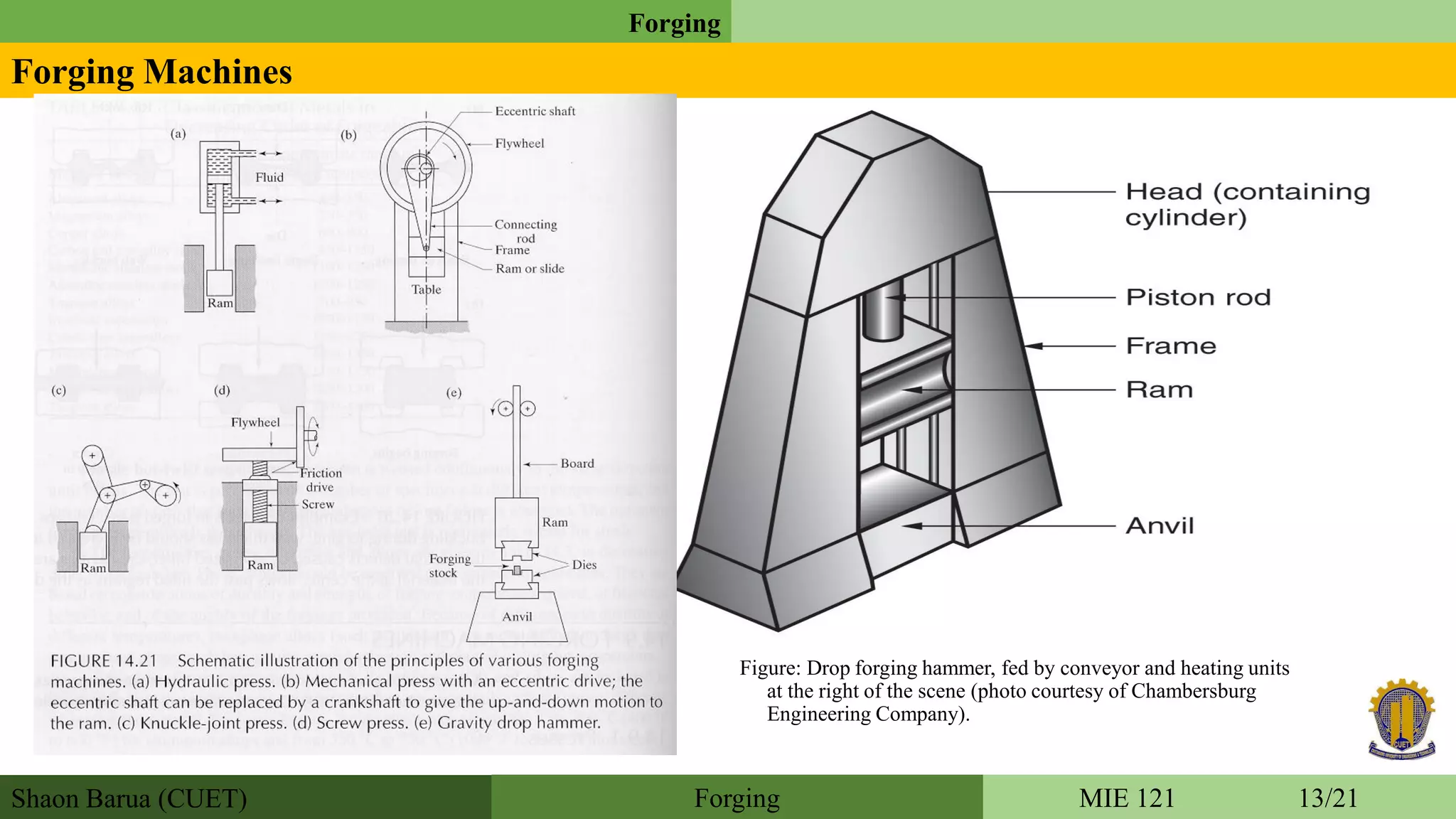

The document discusses various metal forming techniques including open-die forging, impression-die forging, and flashless forging. It describes how each process works and provides examples of parts made using forging. Defects that can occur during forging like unfilled sections, cold shuts, and scale pits are also reviewed. Different types of forging machines like drop hammers and presses are introduced.

![Shaon Barua (CUET)

Forging

MIE 121 20/21Forging

Related videos

1. Forging process animation [https://www.youtube.com/watch?v=aeSCjRaV9Og]

2. Basic forging[https://www.youtube.com/watch?v=FdEFptXI5zk]

3. Generator shaft forging[https://www.youtube.com/watch?v=KwNwN4eRQOA]

4. Open die forging[https://www.youtube.com/watch?v=QwKaKP53HDI]

5. Crankshaft production[https://www.youtube.com/watch?v=J2Y8q-1T4nQ]

6. Friction screw press[https://www.youtube.com/watch?v=a-IlvBmK2Bk]

7. Mechanical forging press[https://www.youtube.com/watch?v=ljRlDwoSNk0]

8. Drop forging hammer[https://www.youtube.com/watch?v=6022lxm0LdU]

Reference Book

1. Chapter 14 [Serope Kalpakjian and Steven R Schmid, Manufacturing Engineering and Technology ]

https://en.wikipedia.org/wiki/Forging]](https://image.slidesharecdn.com/mie121forging-2-170325101145/75/Forging-process-20-2048.jpg)

![Shaon Barua (CUET)

Forging

MIE 121 21/21Forging

You should be able to answer

Reference Book

1. Chapter 14 [Serope Kalpakjian and Steven R Schmid, Manufacturing Engineering and Technology ]

https://en.wikipedia.org/wiki/Forging]

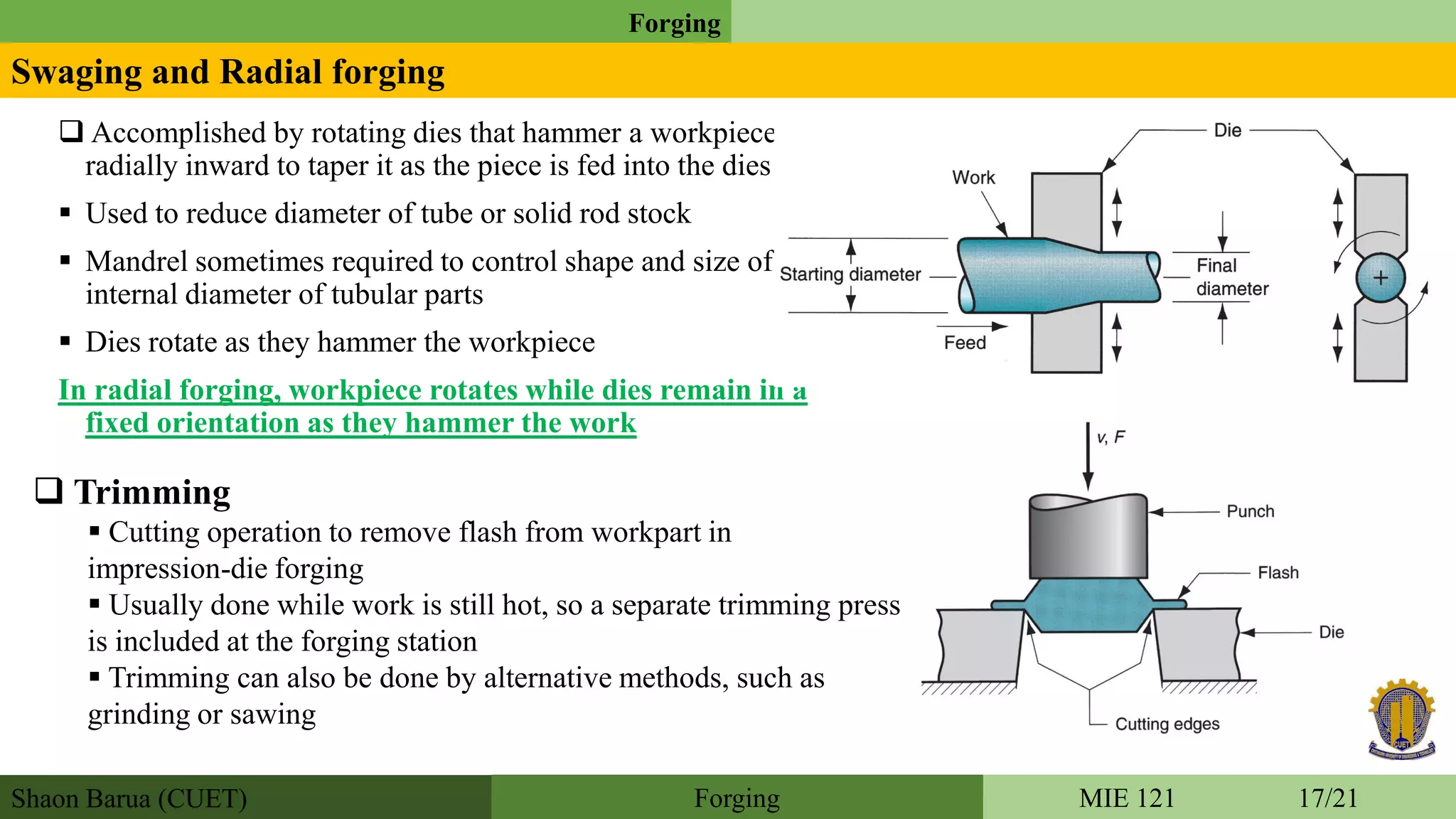

Coning operation, heading, swaging, cogging operation

Different aspects of open-die forging and impression die forging

Defects of forging

Steel ball preparation](https://image.slidesharecdn.com/mie121forging-2-170325101145/75/Forging-process-21-2048.jpg)