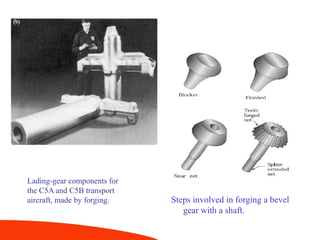

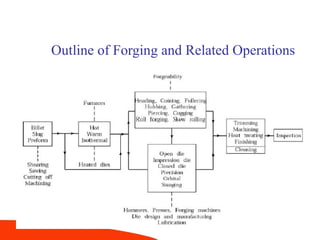

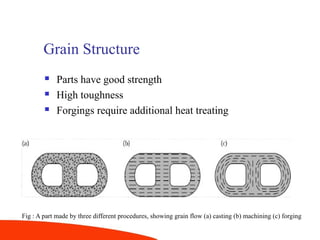

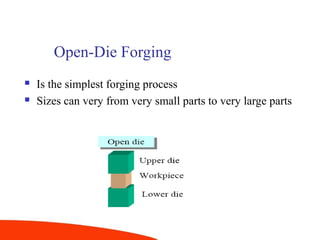

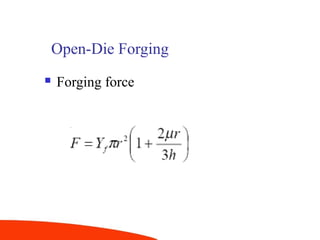

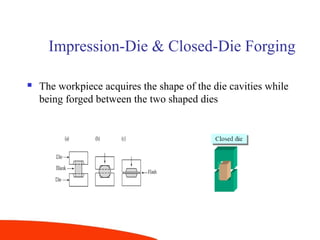

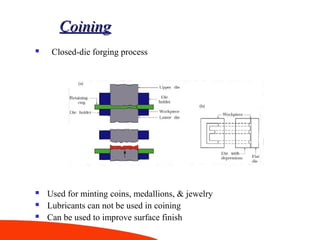

Forging is an ancient metalworking process where a metal is compressed under force into a desired shape. It can be done using a hammer and anvil and produces parts with good strength and toughness. There are different types of forging processes, including open-die forging using flat dies, impression-die forging where the workpiece takes the shape of shaped die cavities, and coining where parts are precisely forged without lubricants between dies. Forged parts often require additional heat treating for optimal properties.