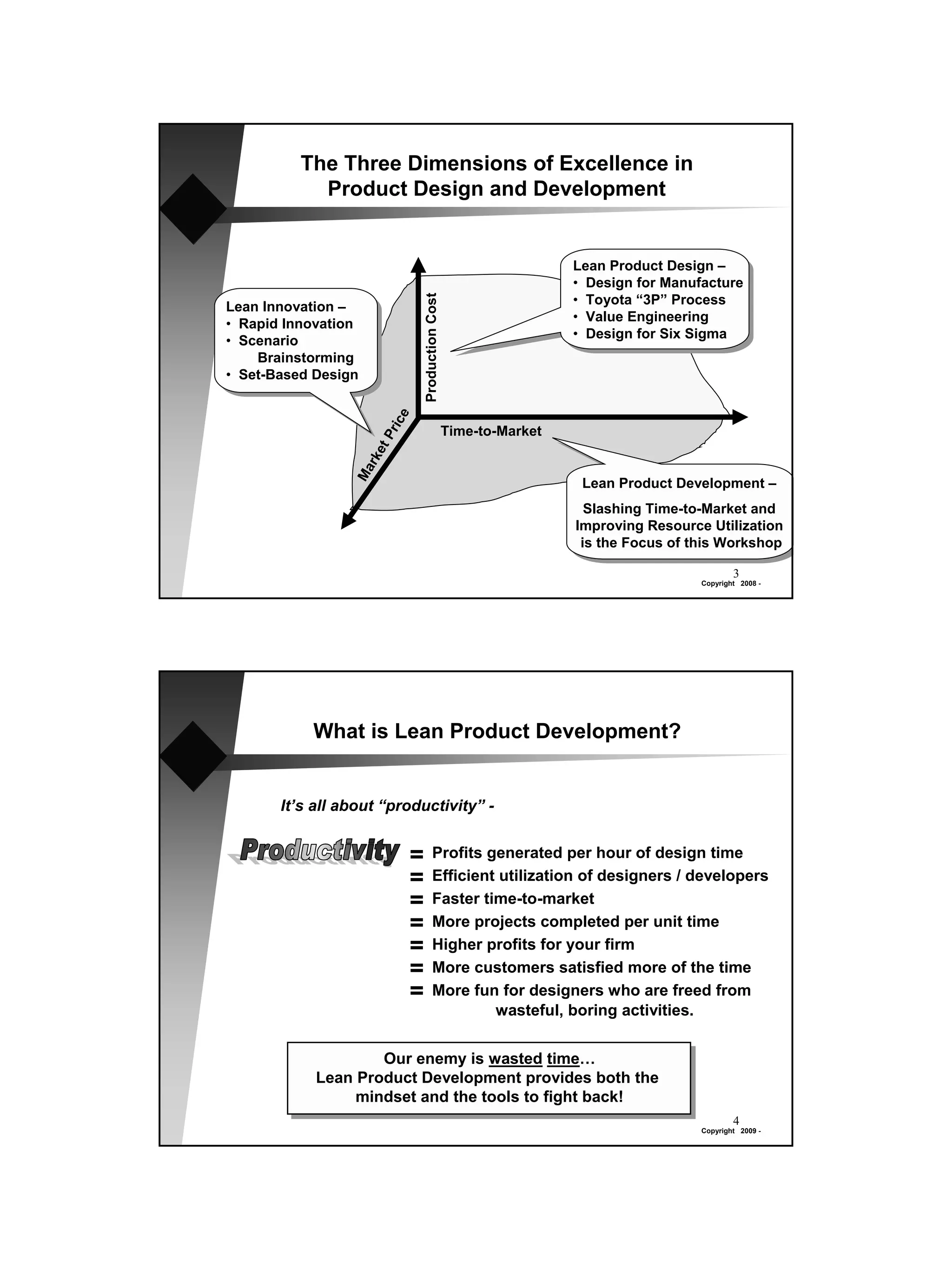

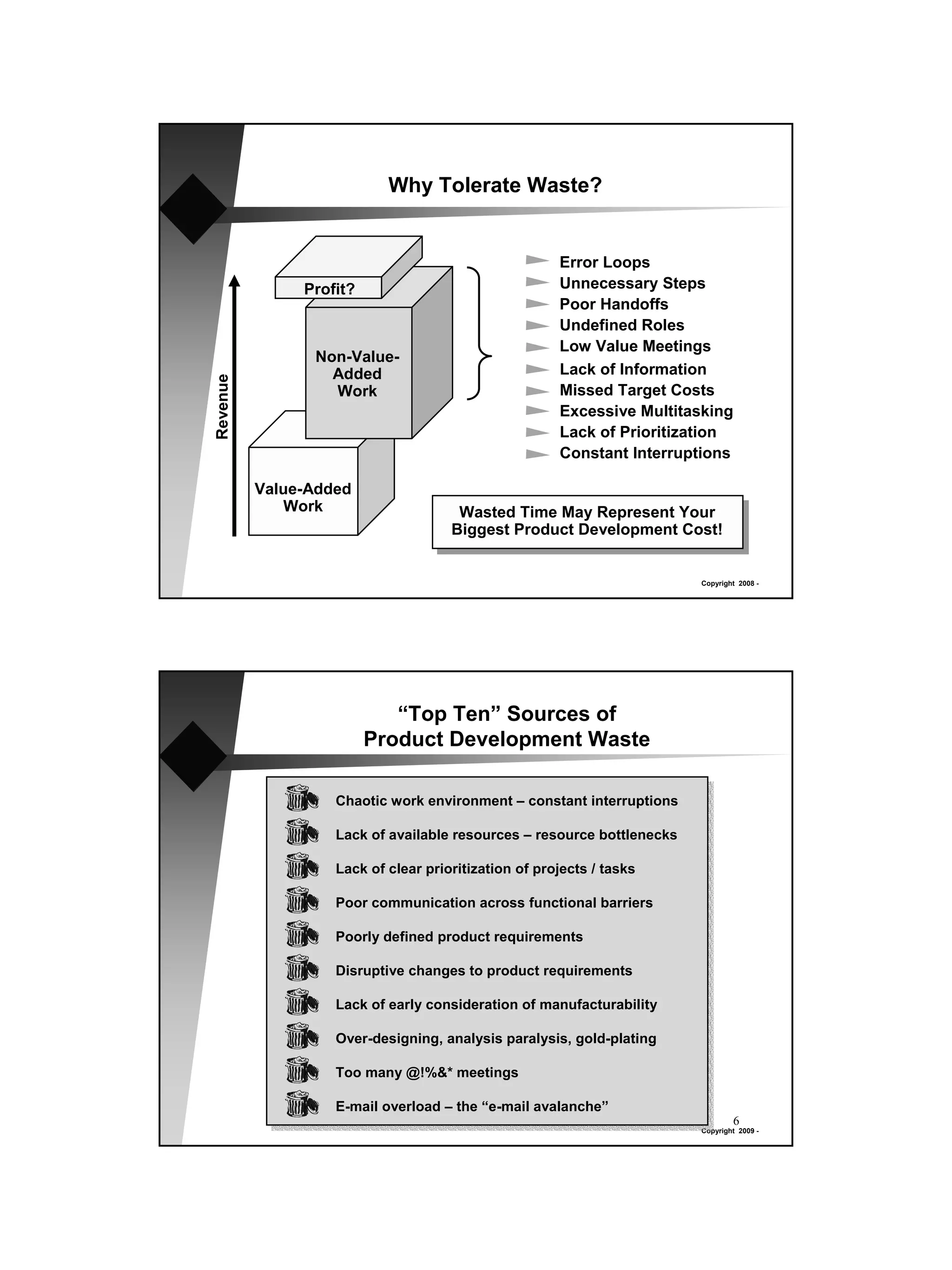

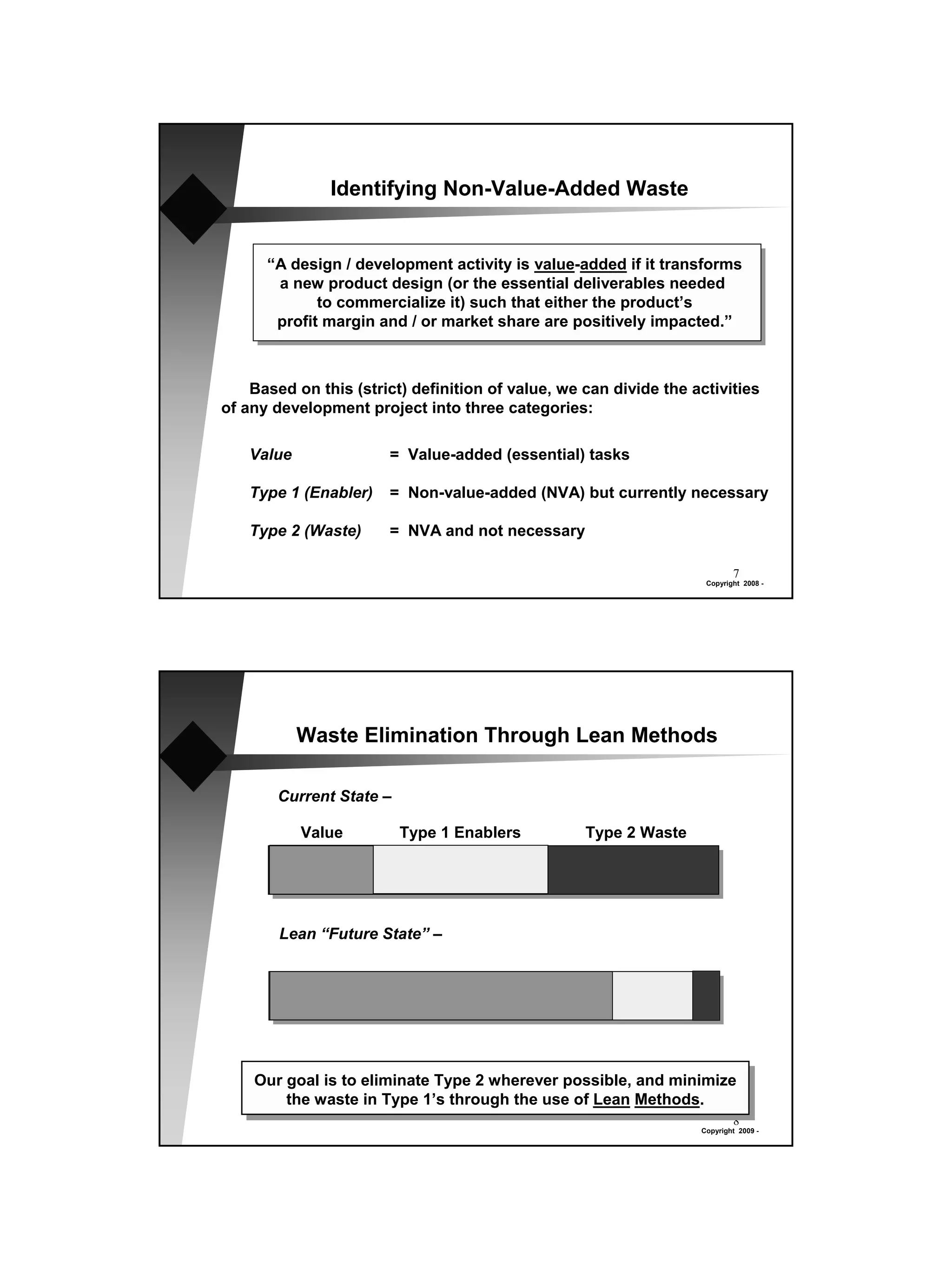

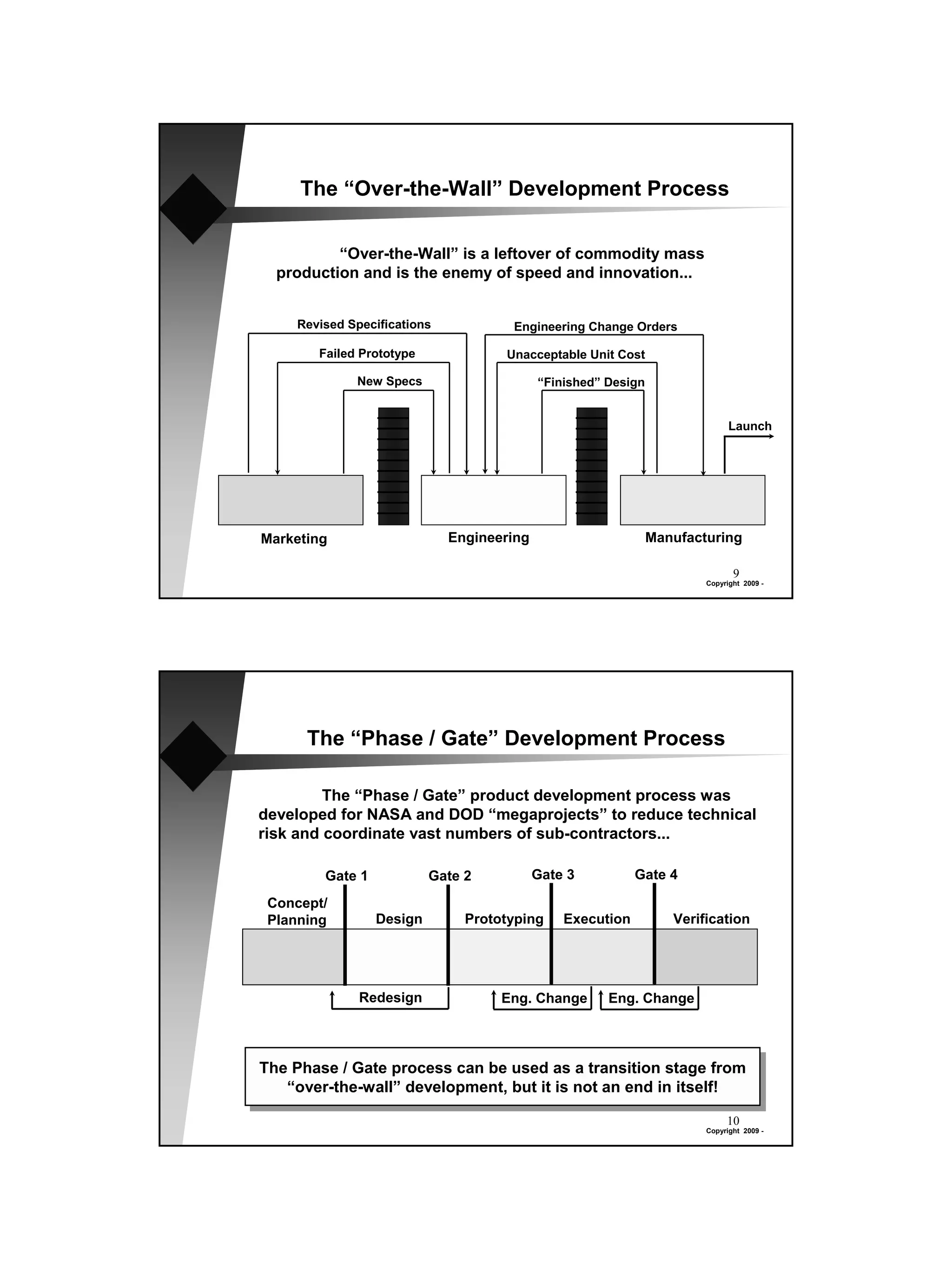

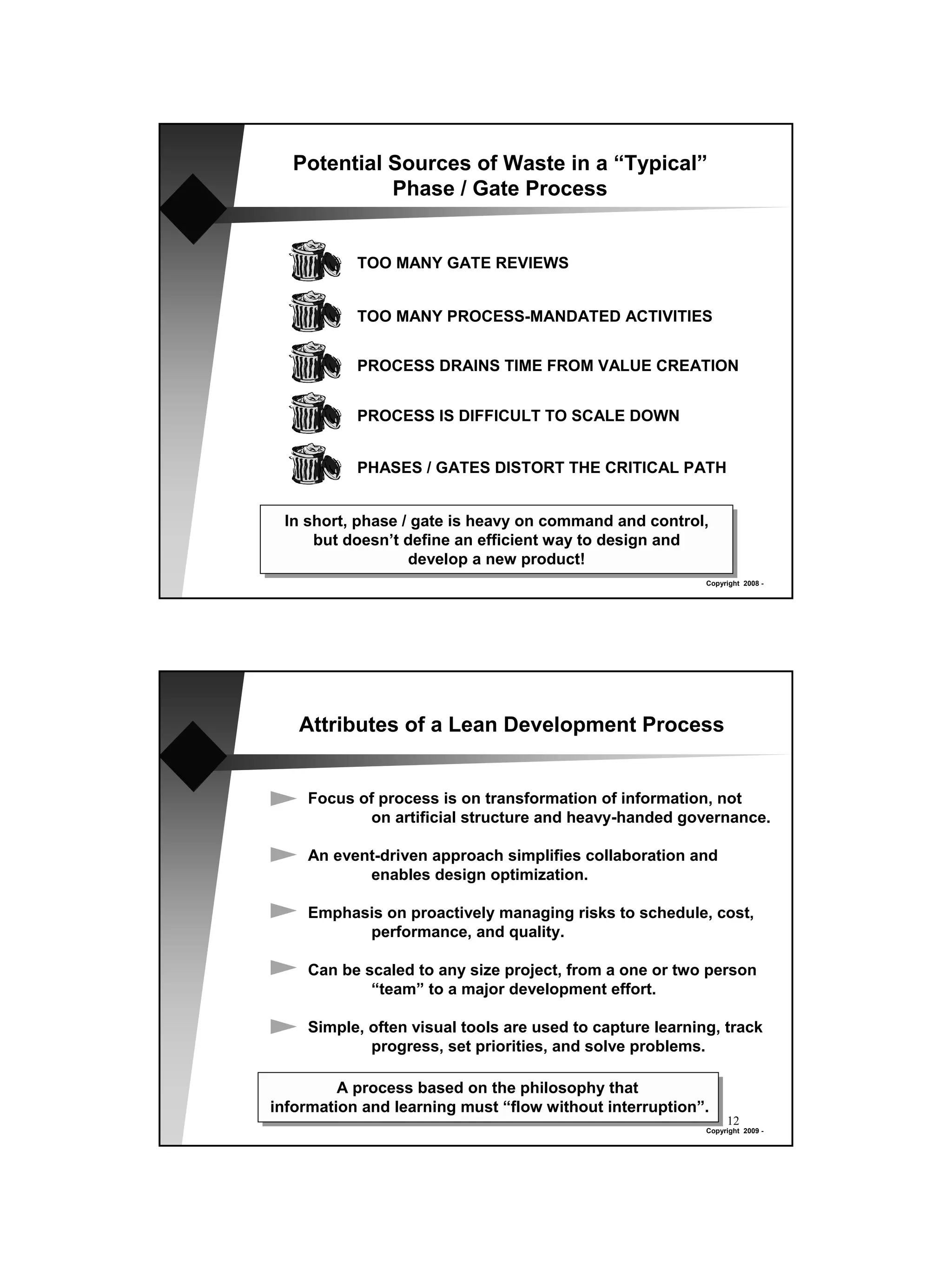

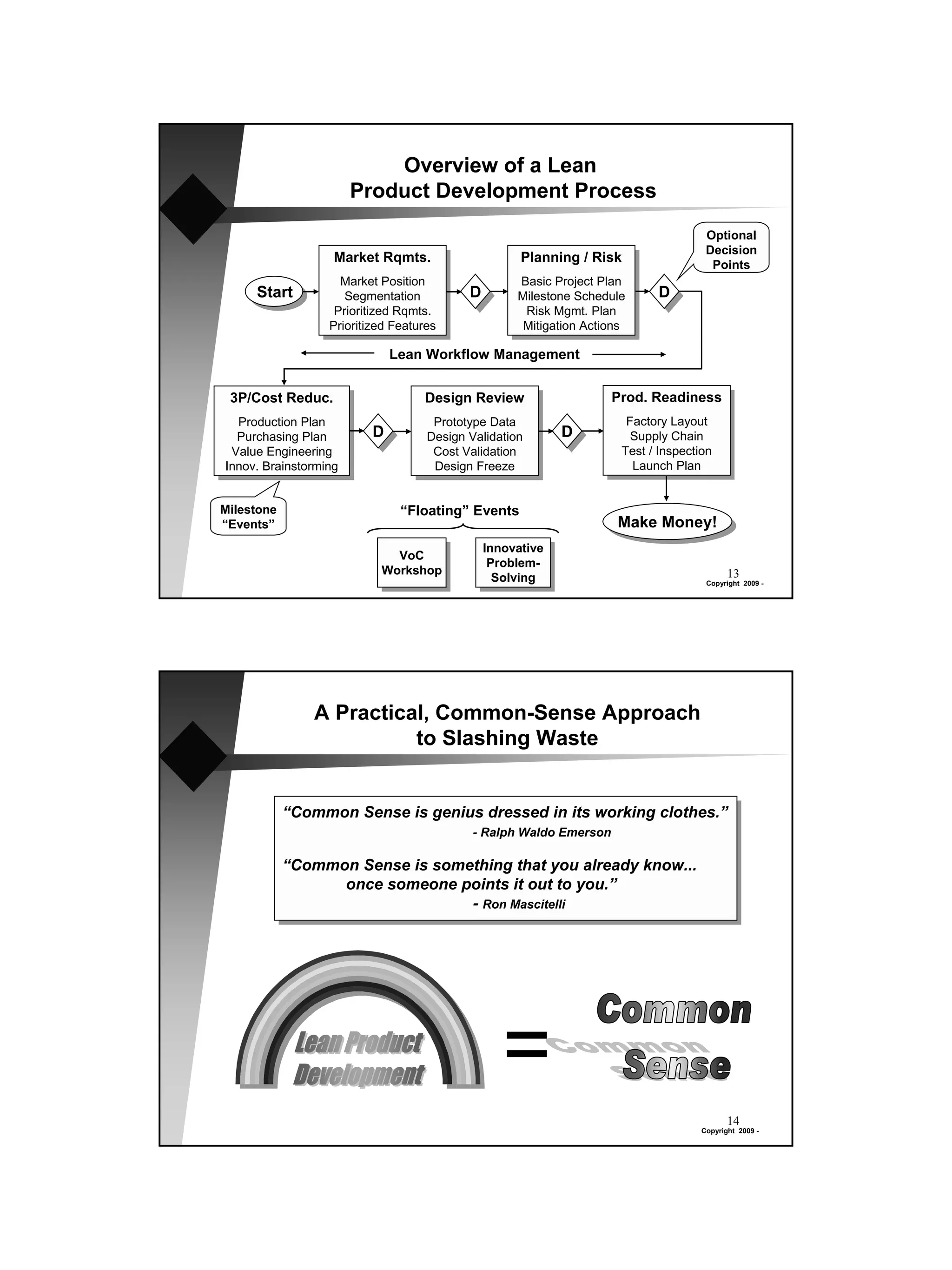

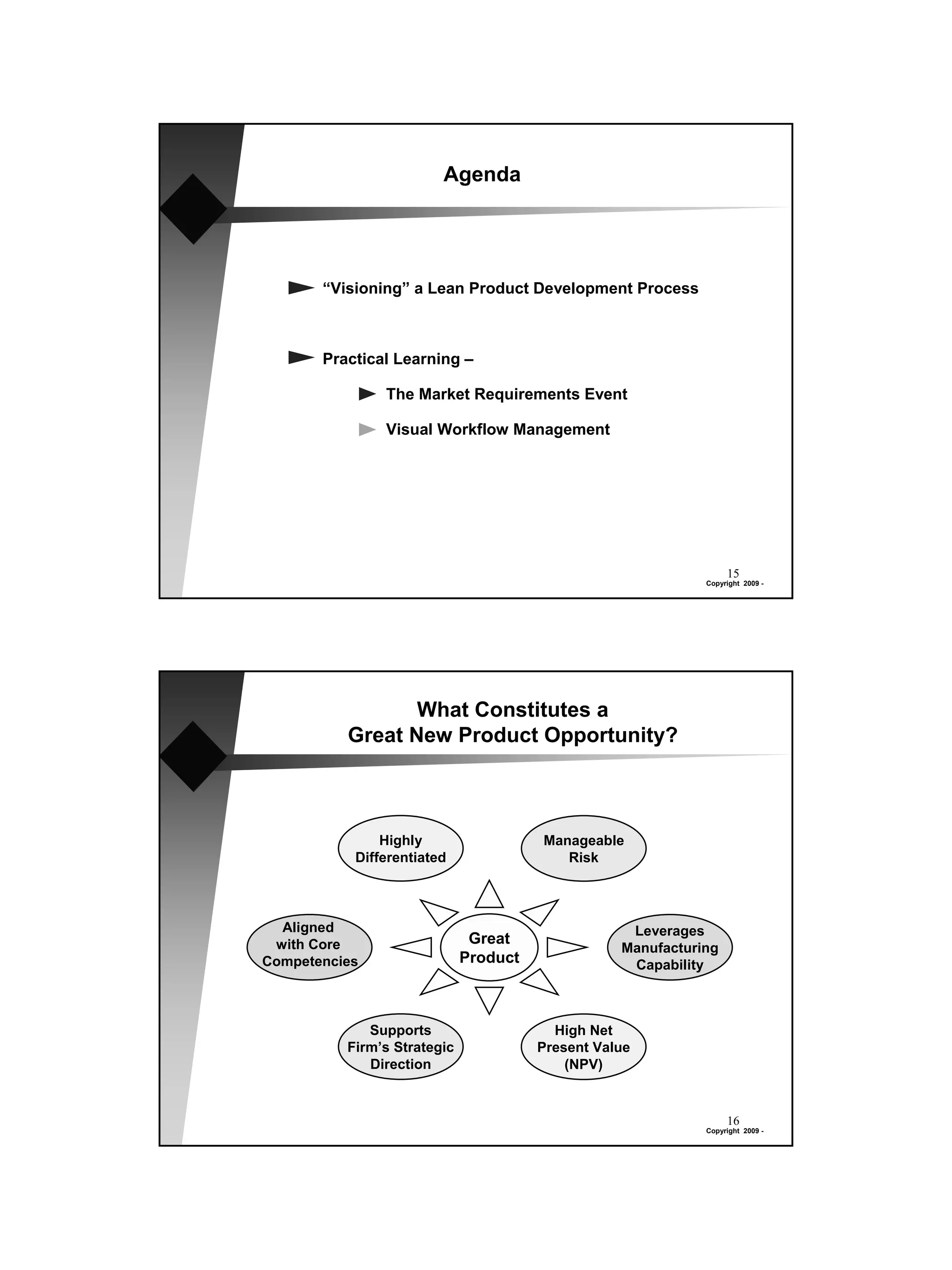

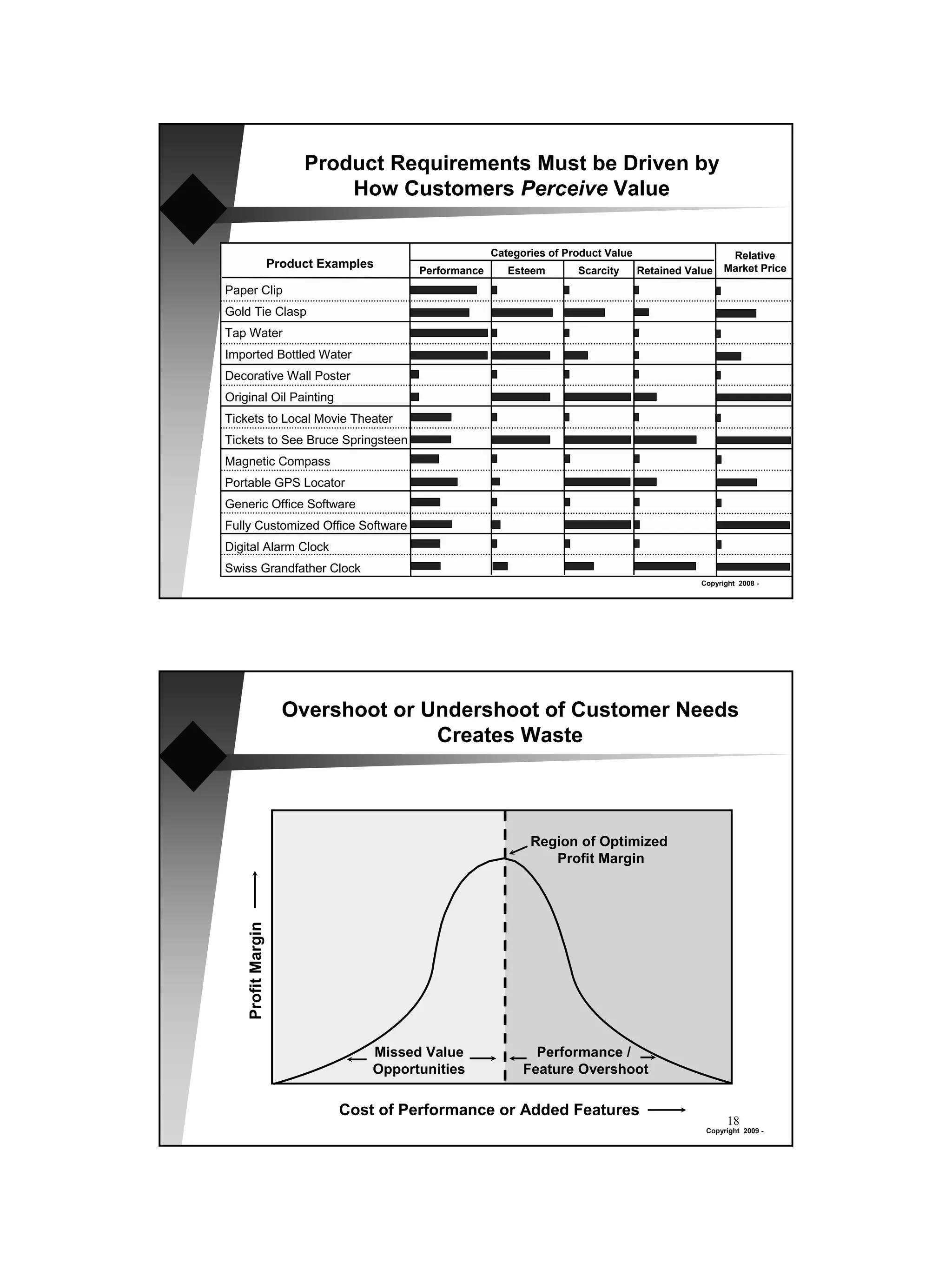

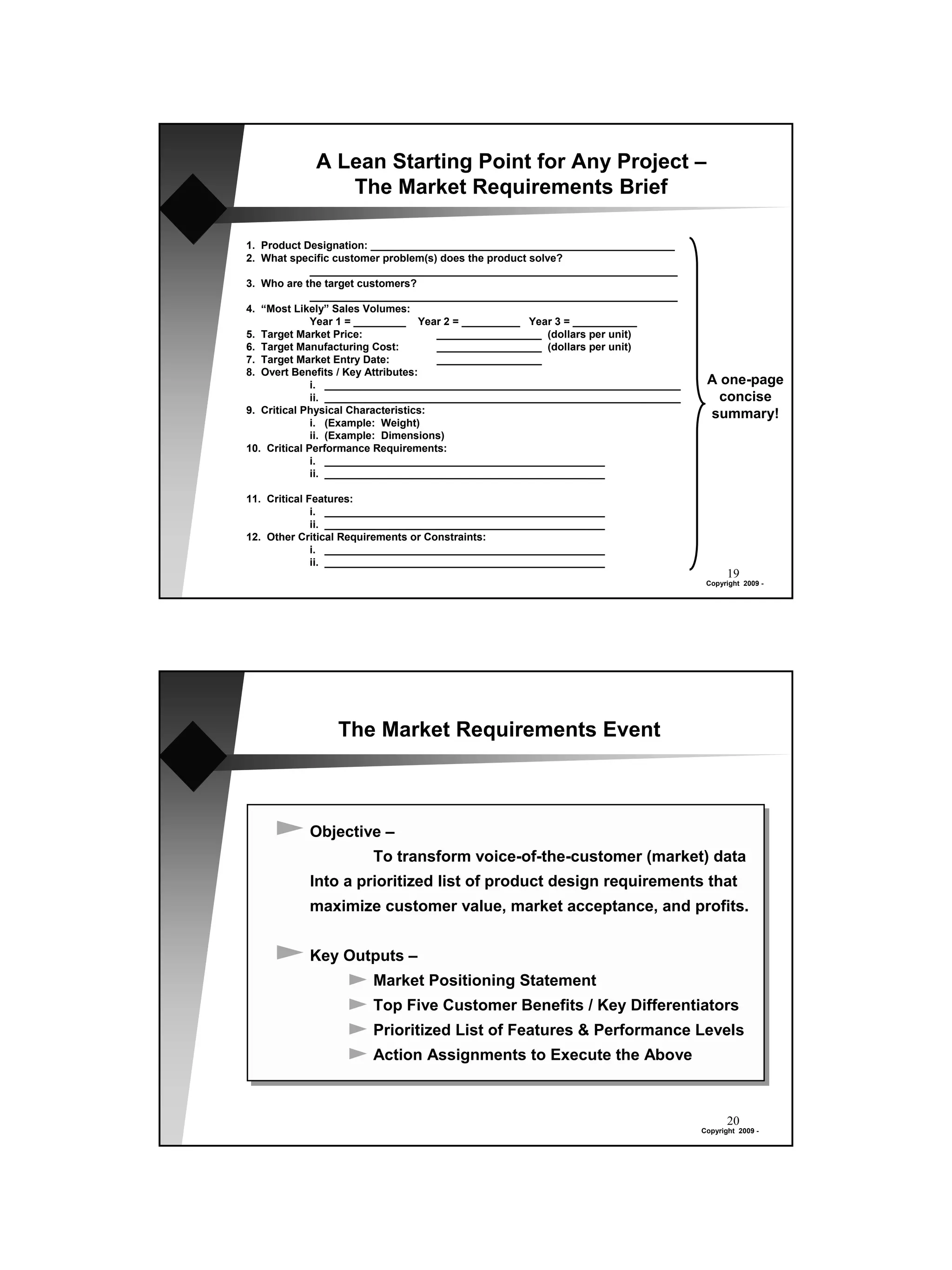

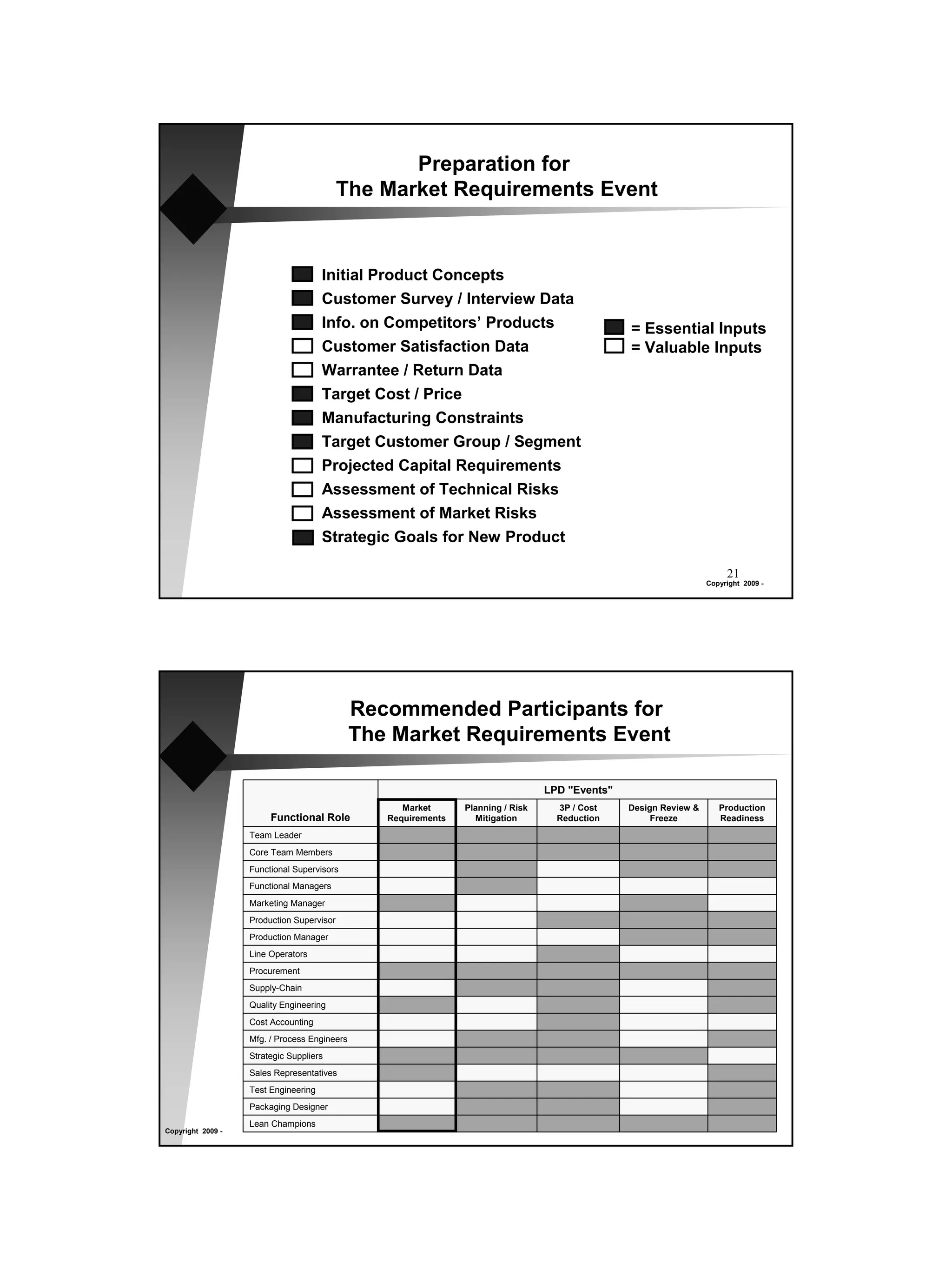

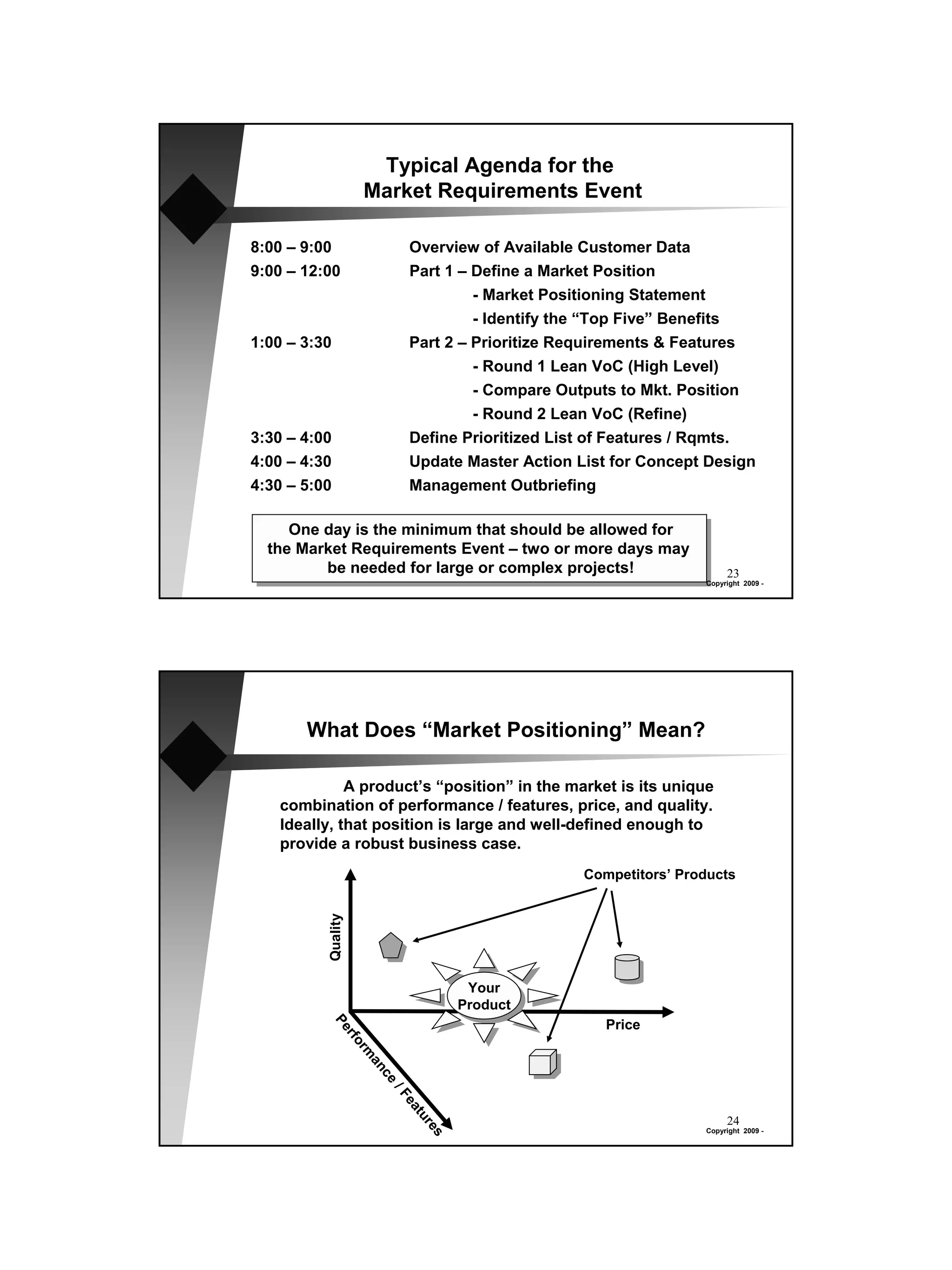

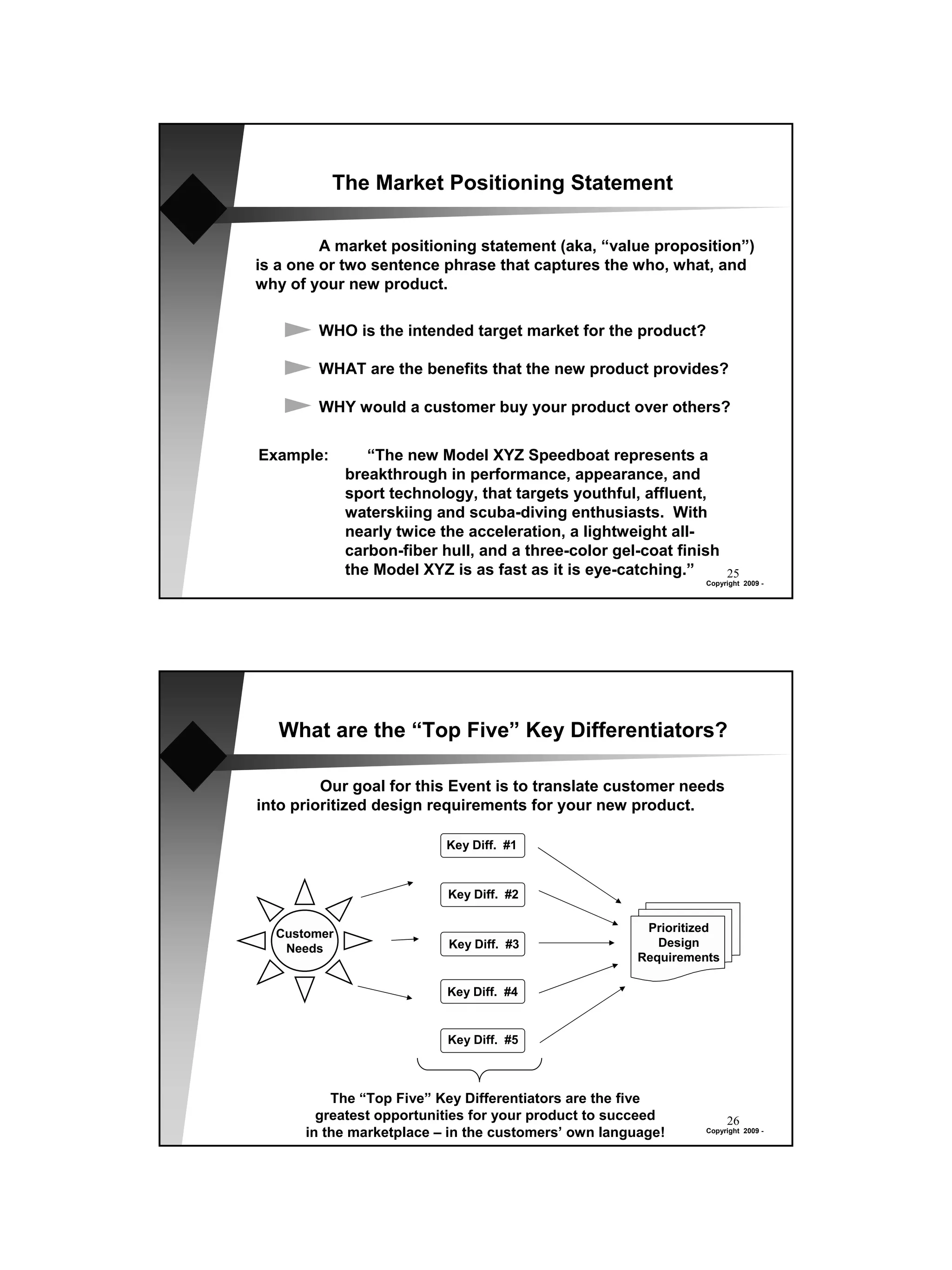

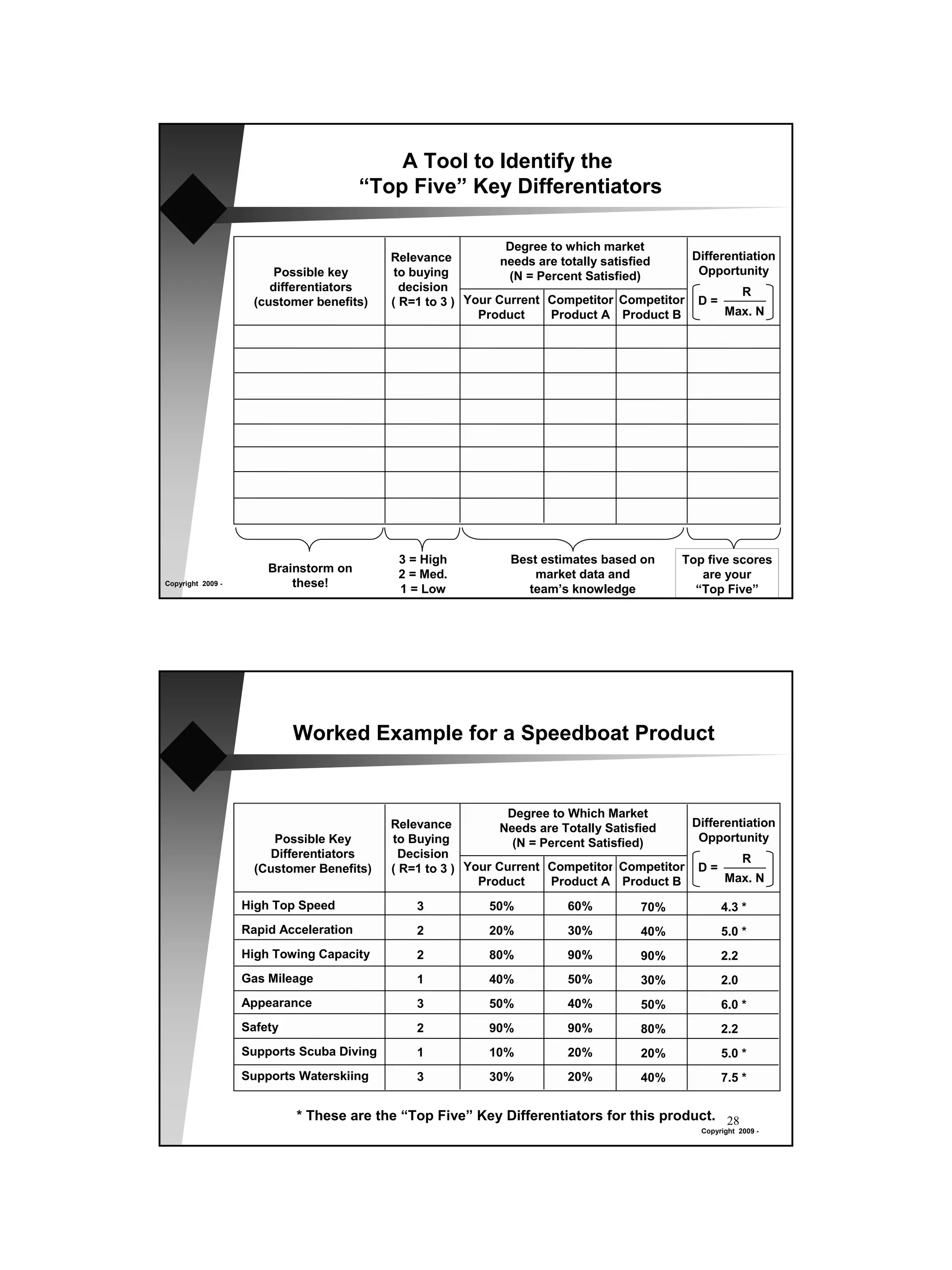

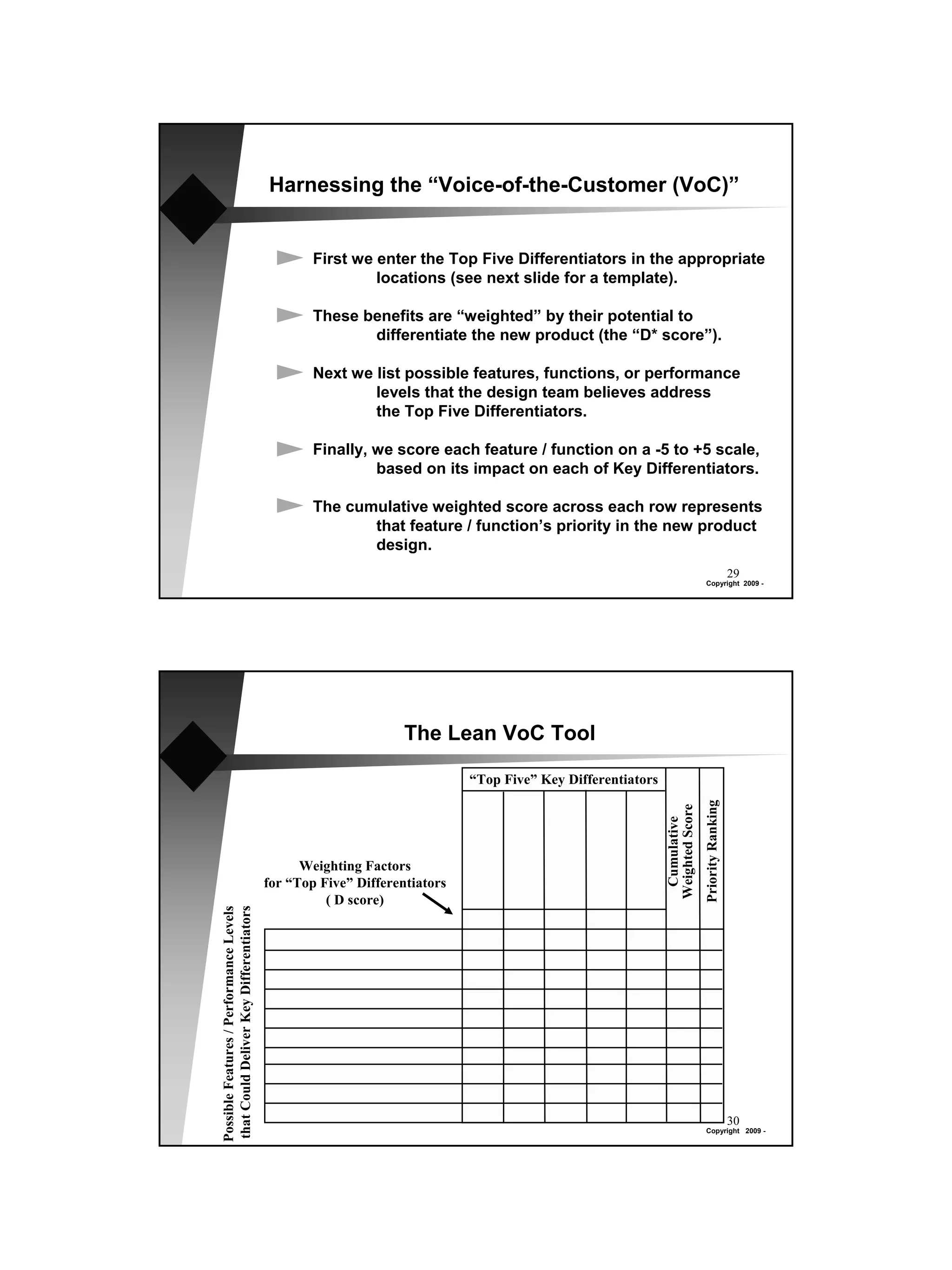

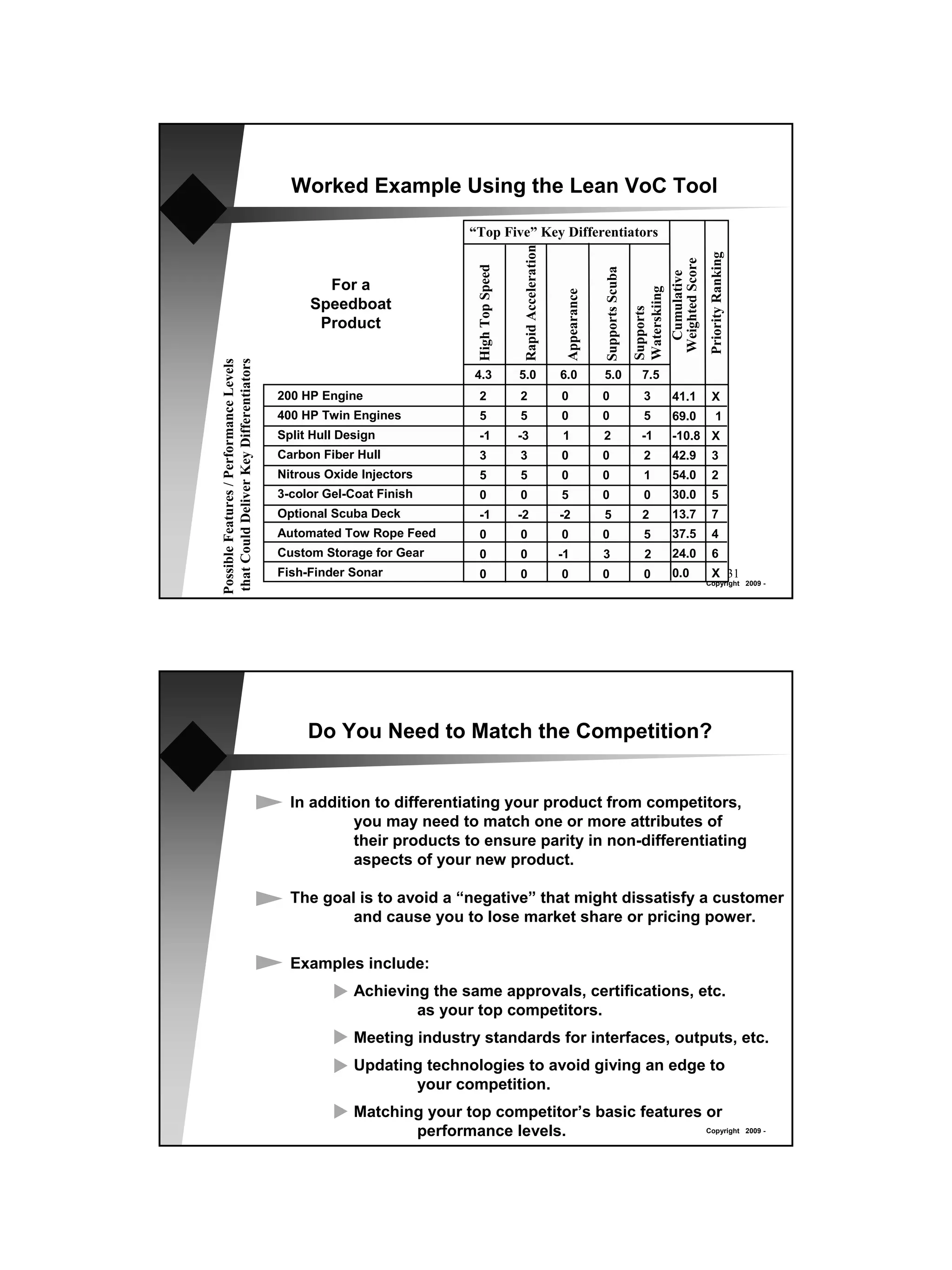

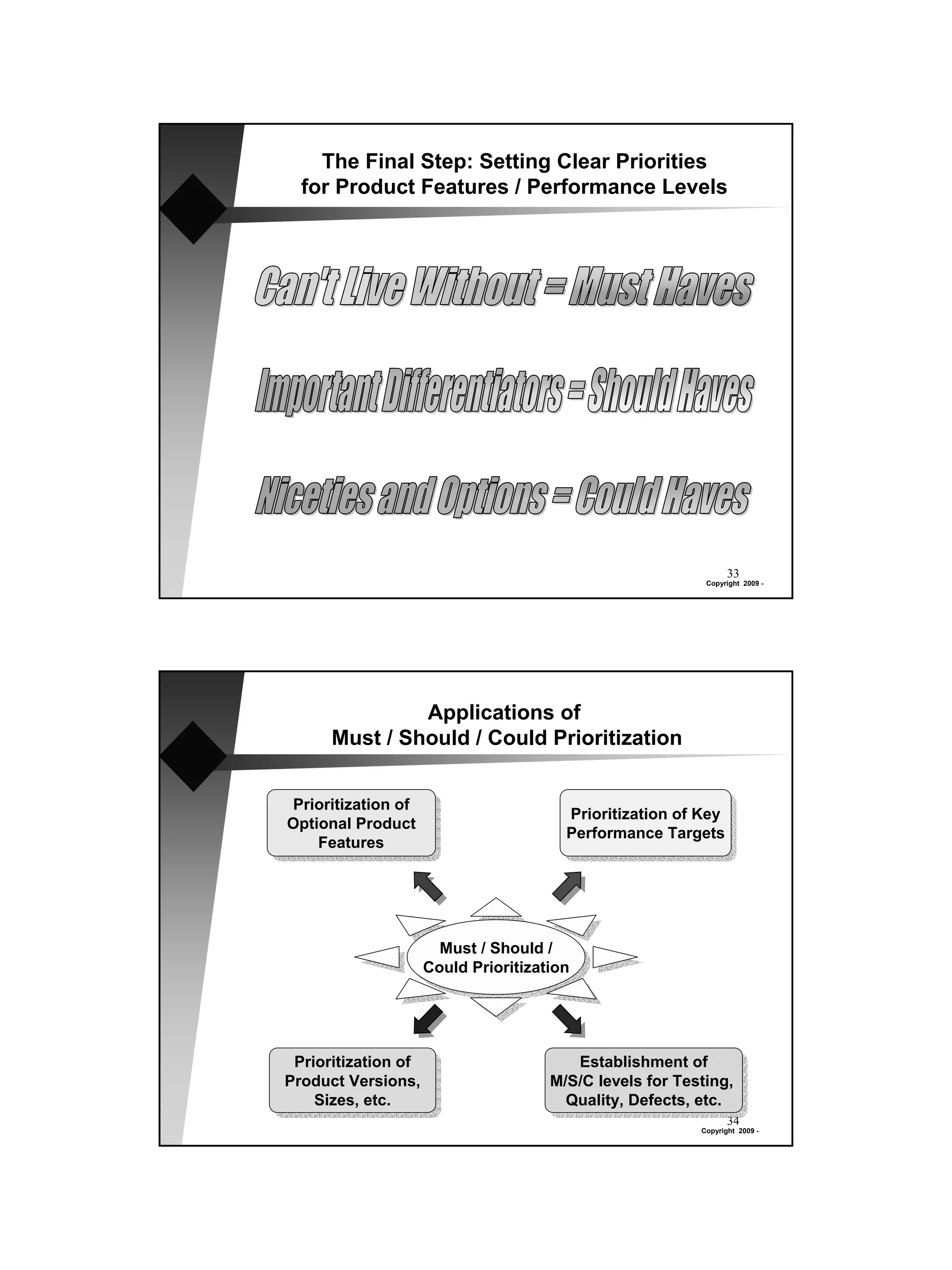

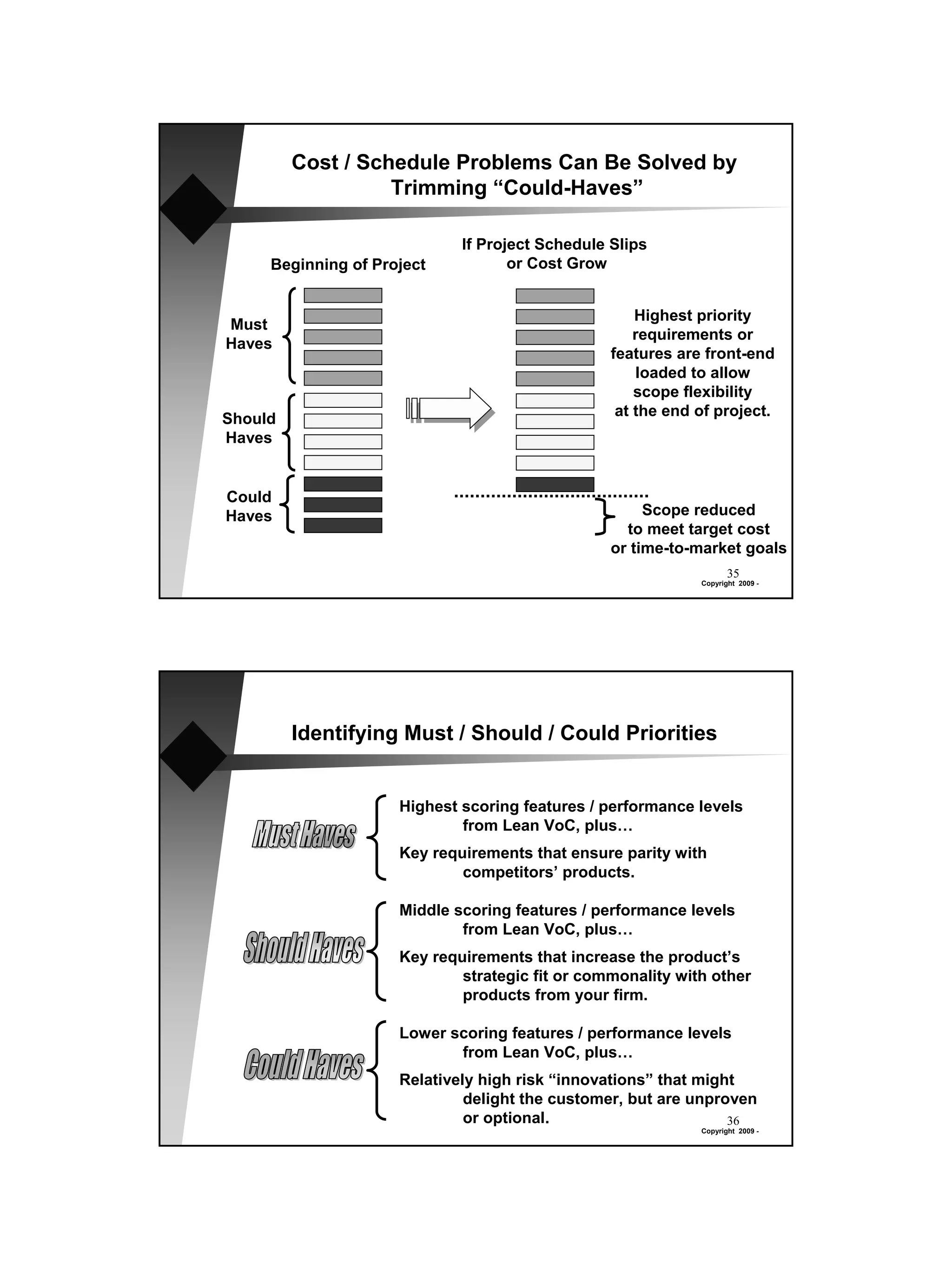

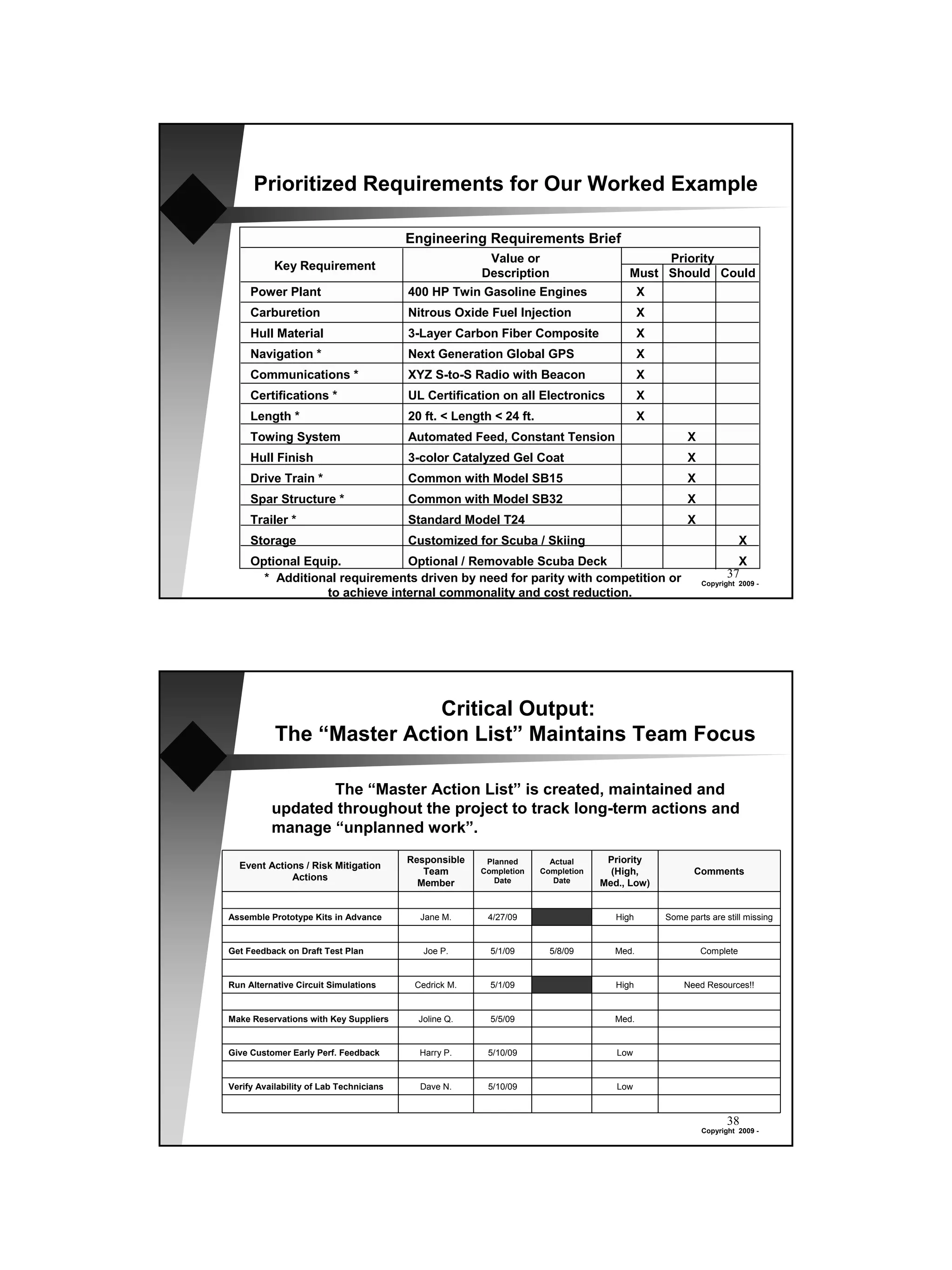

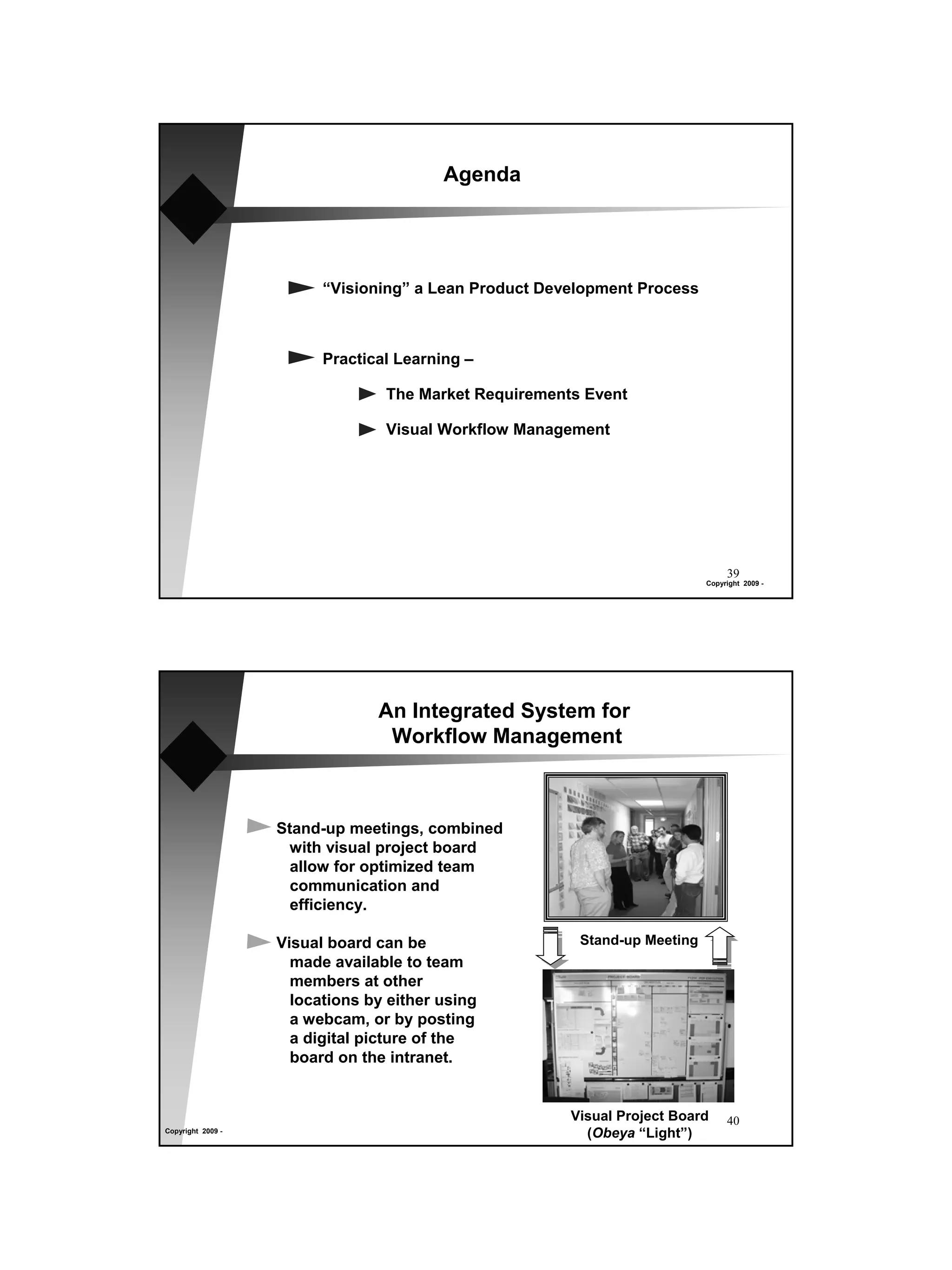

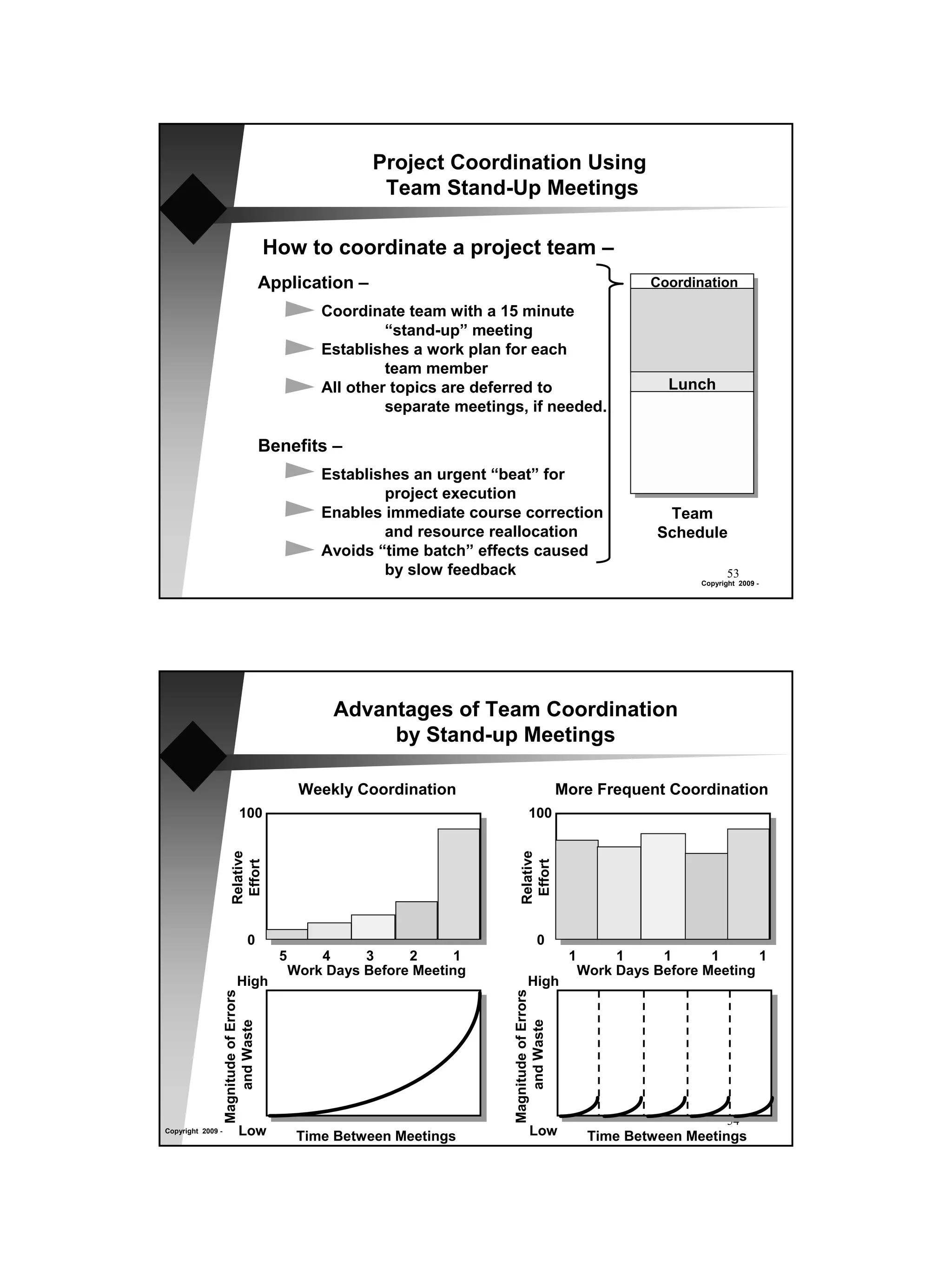

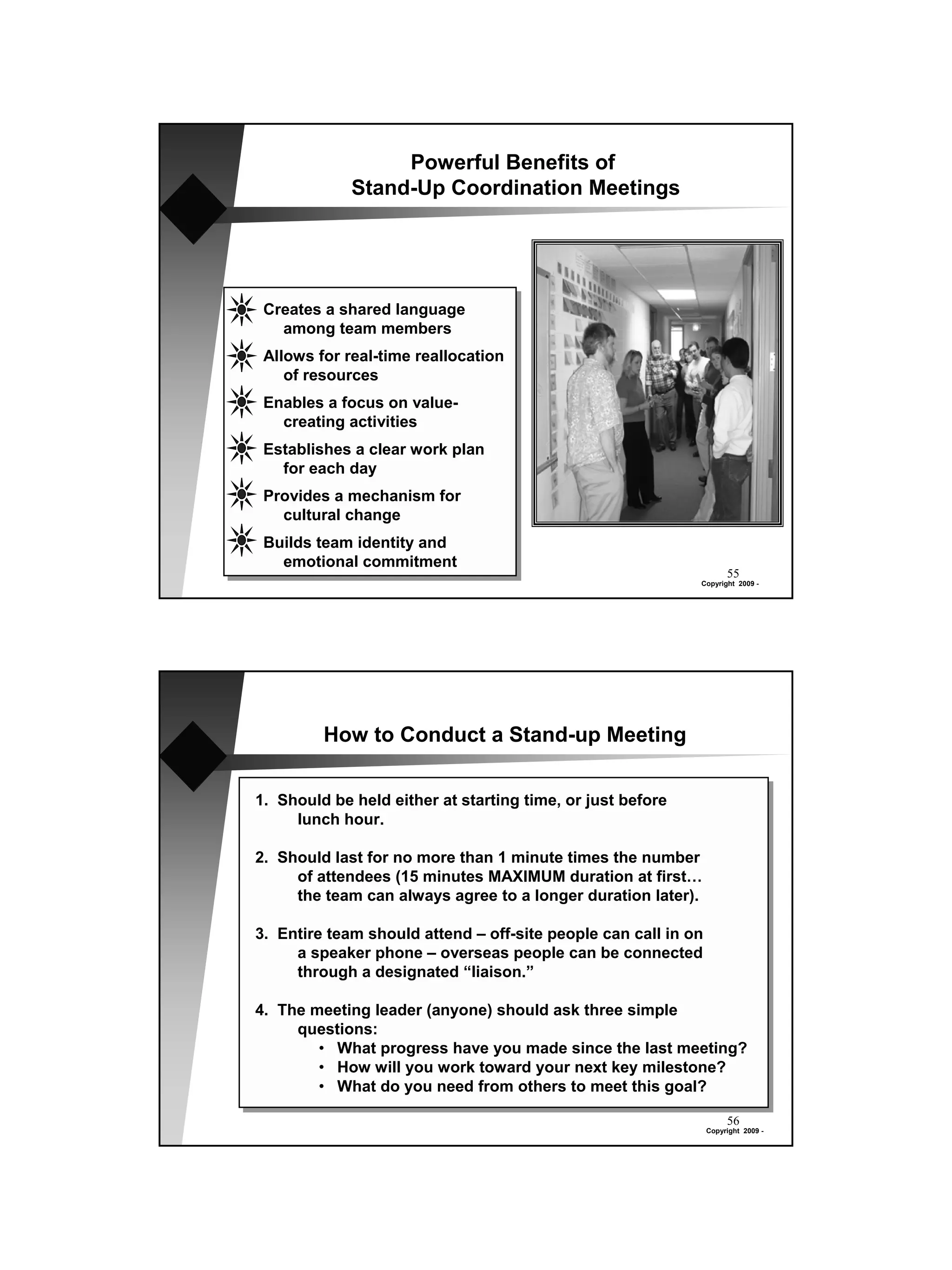

The document outlines a workshop on lean product development led by Ron Mascitelli, focusing on reducing waste and improving efficiency in product design processes. It emphasizes the importance of understanding market requirements, prioritizing features, and employing tools to enhance collaboration and innovation. Key methods discussed include eliminating non-value-added activities, utilizing visual workflow management, and transforming customer voice data into actionable product design criteria.