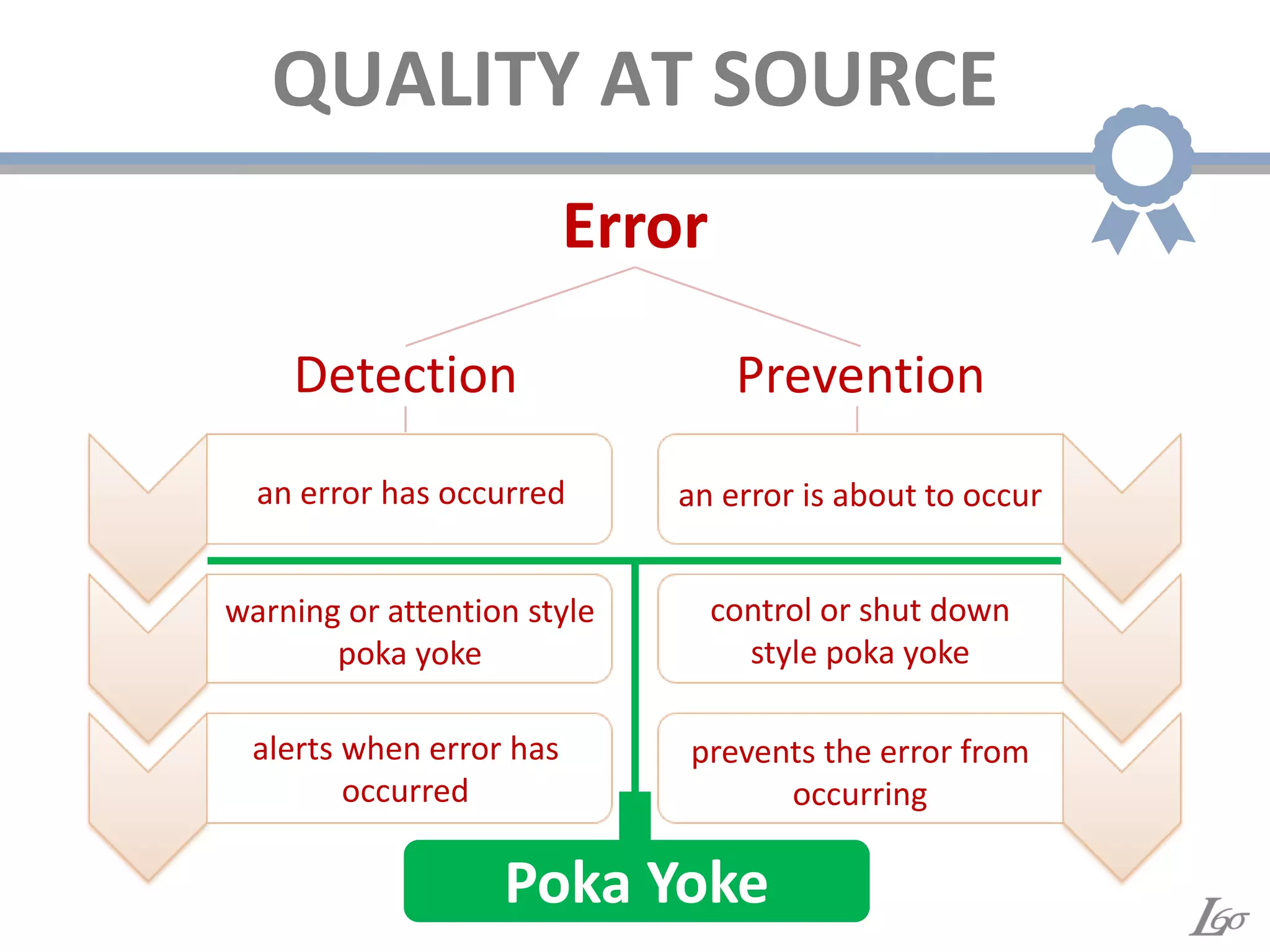

Poka yoke is a simple, cost-effective device designed to catch or prevent errors at their source, ensuring 100% inspection and feedback to stop defects from reaching the customer. It operates on levels of effectiveness, from detecting defects downstream to preventing them entirely through innovative solutions. Examples of poka yoke include visual aids for inspections, contrast in paint, and automated systems that stop errors before they occur.