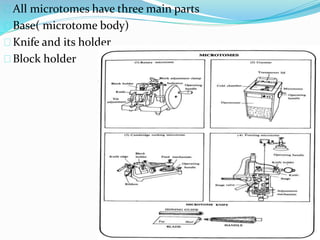

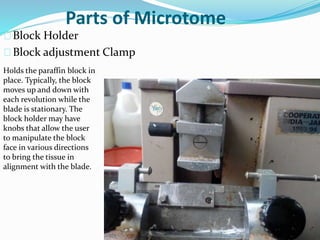

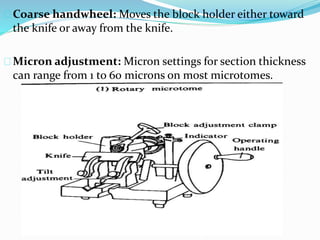

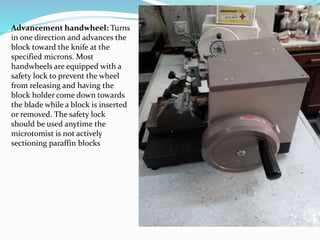

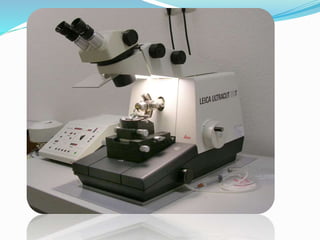

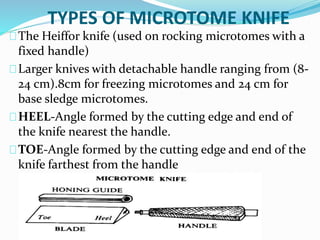

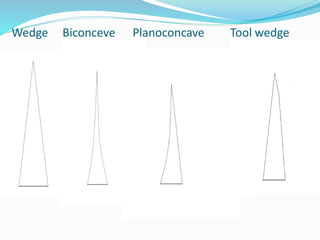

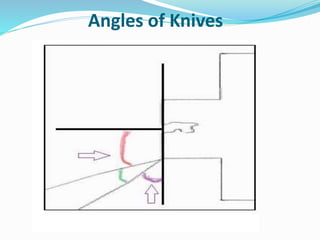

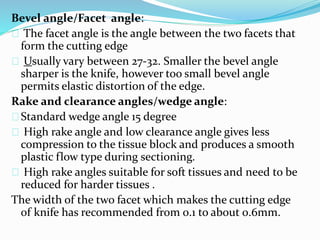

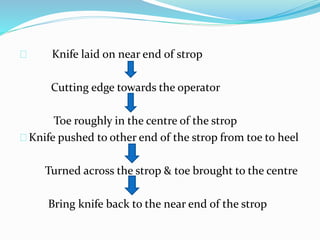

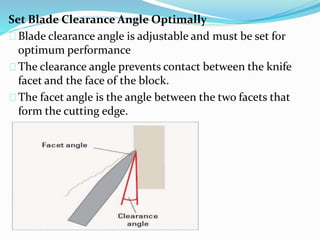

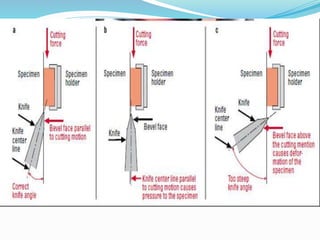

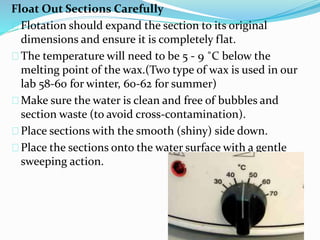

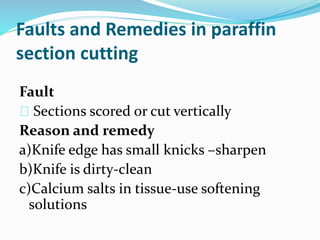

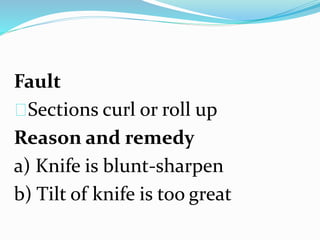

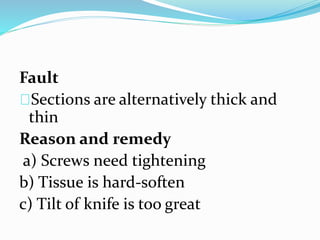

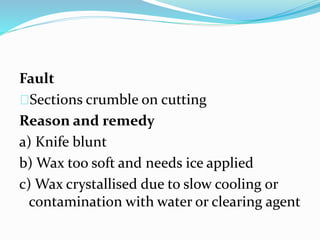

This document discusses various types of microtomes and microtomy techniques. It describes different parts of microtomes like the block holder, knife holder, and handwheels. It explains different types of microtomes based on their cutting mechanism, including rotary, rocking, base-sledge, sliding, freezing, vibrating, saw, cryostat, and ultramicrotome. It also discusses microtome knives, sharpening techniques, section cutting for paraffin blocks, and section mounting methods.