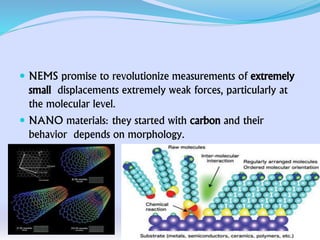

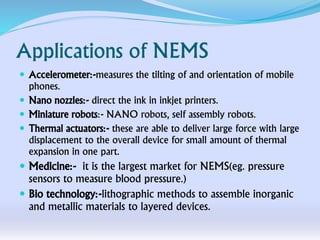

This document discusses micro and nano electromechanical systems (MEMS and NEMS). It begins by explaining Richard Feynman's vision of building small machines and devices. It then defines MEMS and NEMS as devices that convert electrical and mechanical energy. Examples of MEMS applications include sensors, optical devices, and fluidic systems. NEMS promise even smaller devices for applications like accelerometers, inkjet nozzles, and medicine. The document outlines fabrication techniques for MEMS like deposition, lithography, and etching. It concludes by noting the future potential of these technologies and references for further information.