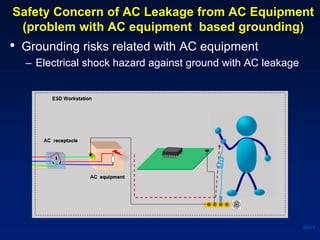

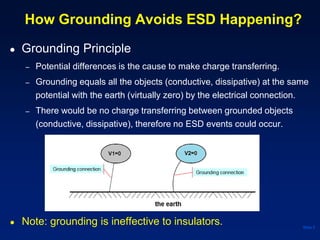

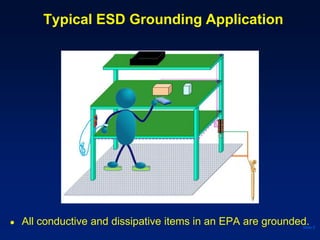

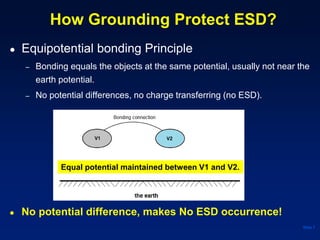

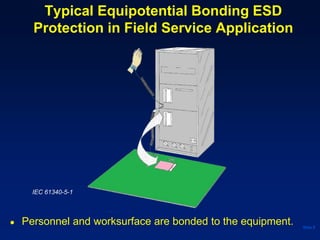

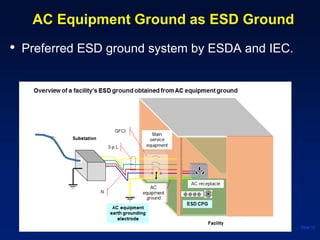

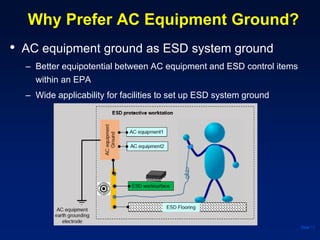

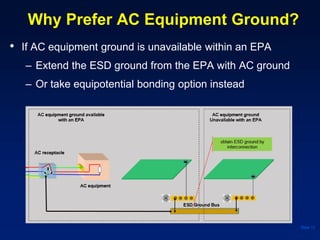

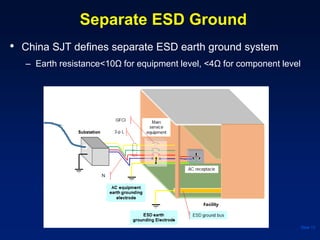

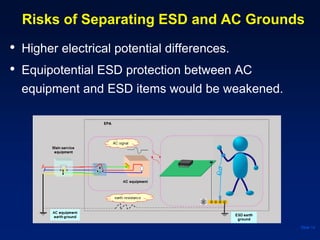

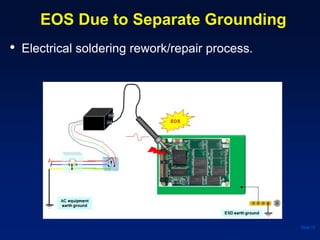

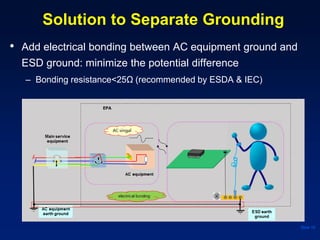

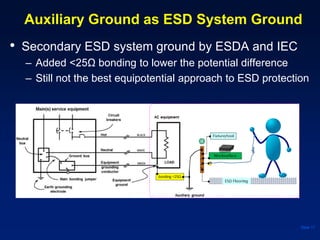

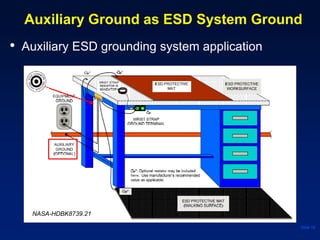

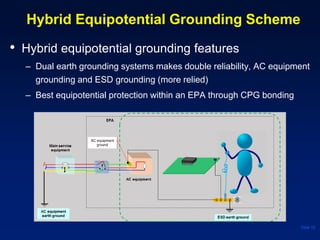

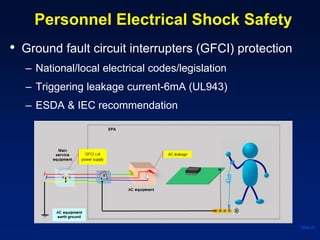

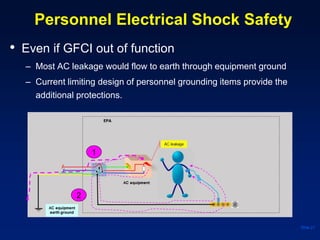

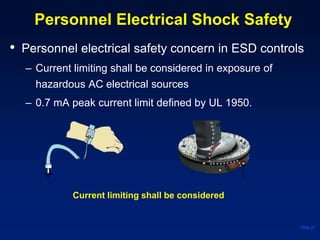

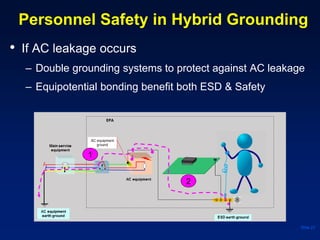

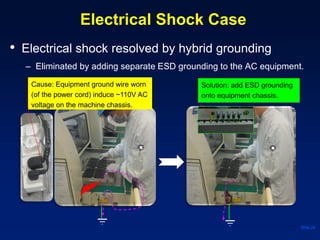

This document discusses grounding system design for electrostatic discharge (ESD) protection. It analyzes the effectiveness of different grounding schemes, including those based on alternating current (AC) equipment ground, separated ground, and auxiliary ground. The document proposes a hybrid grounding scheme that provides double reliability through both AC equipment grounding and a separate ESD ground connected by equipotential bonding. This approach best equalizes potential for ESD protection while ensuring personnel safety from AC leakage through features like ground fault circuit interrupters.