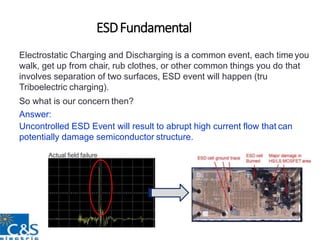

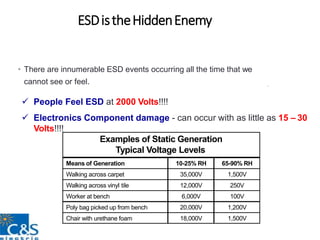

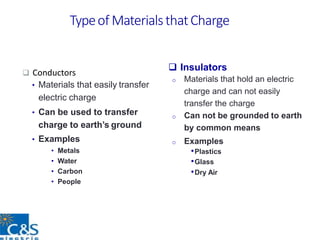

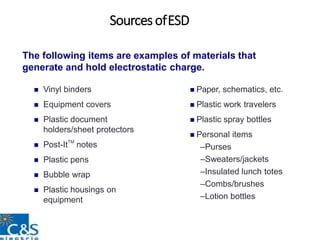

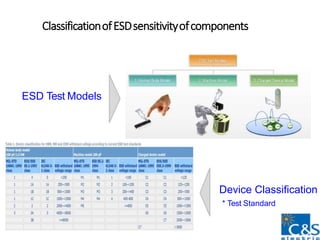

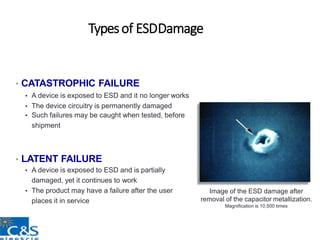

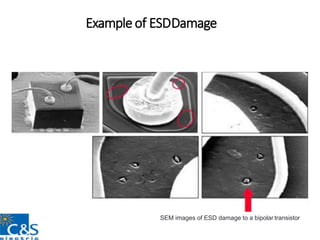

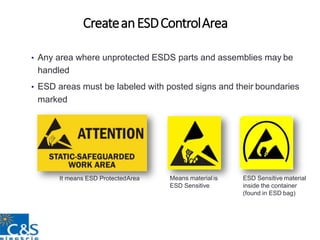

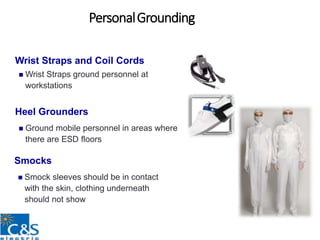

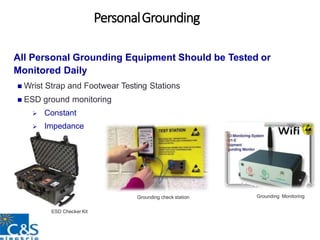

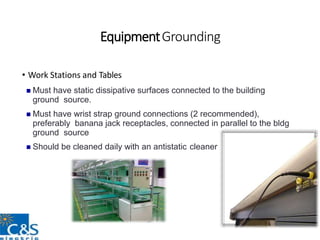

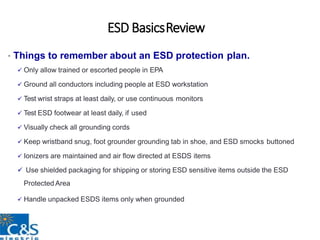

The document provides a comprehensive overview of electrostatic discharge (ESD) and its implications in electronics and semiconductor manufacturing, focusing on definitions, causes, types of damage, and control measures. ESD can result in catastrophic or latent failures of sensitive components, incurring significant costs for the industry. The training includes ESD control programs, safe handling procedures, grounding techniques, and the importance of creating designated ESD protected areas.