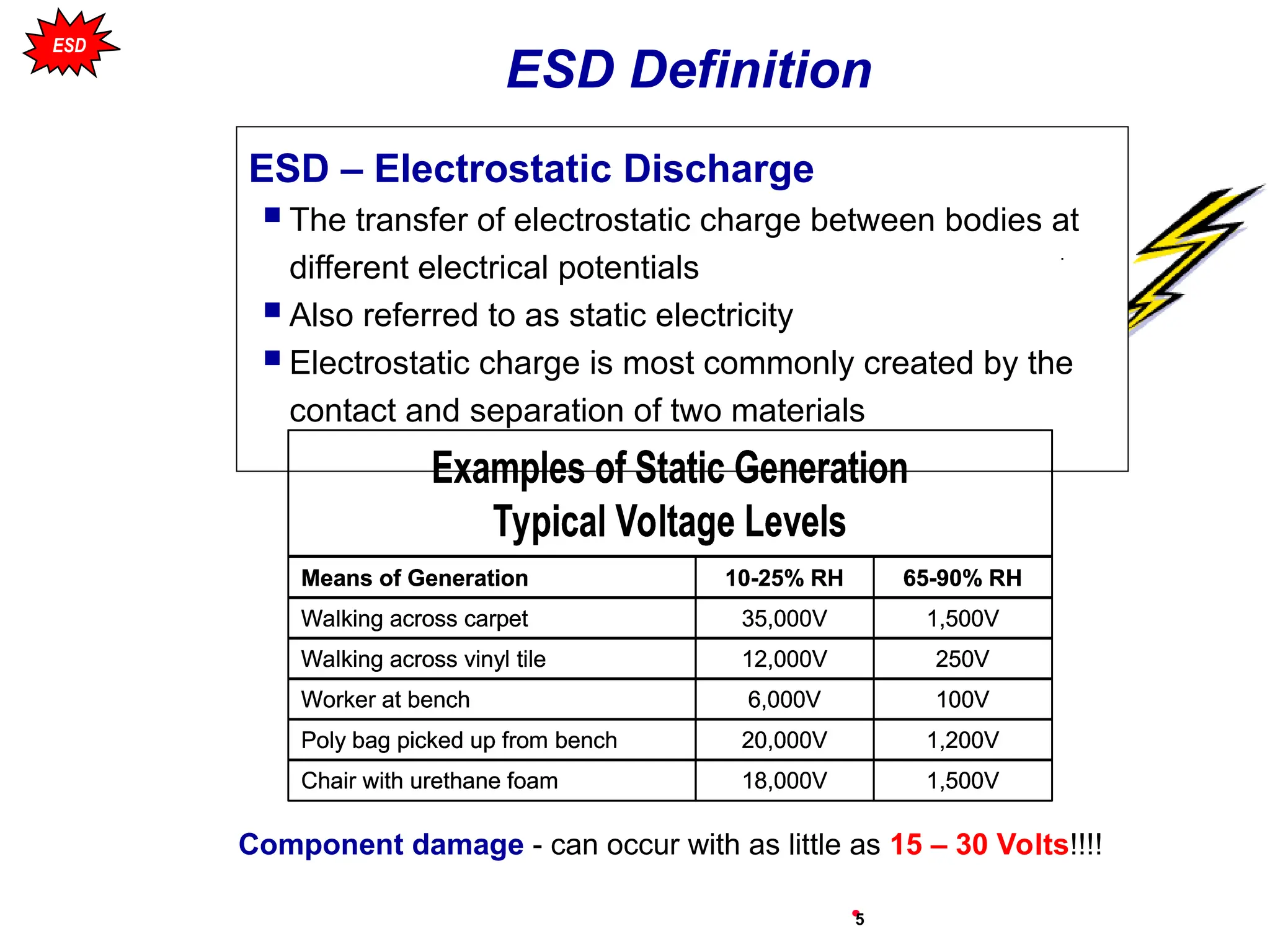

The document outlines an ESD (Electrostatic Discharge) training program aimed at educating employees about ESD, its significance, and prevention strategies. It details the types of ESD sensitive components, common causes and sources of ESD, and establishes roles and responsibilities for individuals within ESD control areas, emphasizing the importance of proper equipment and personal grounding. Furthermore, it includes a hands-on demonstration, assessment reviews, and management responsibilities to maintain effective ESD control measures.

![ESD

53

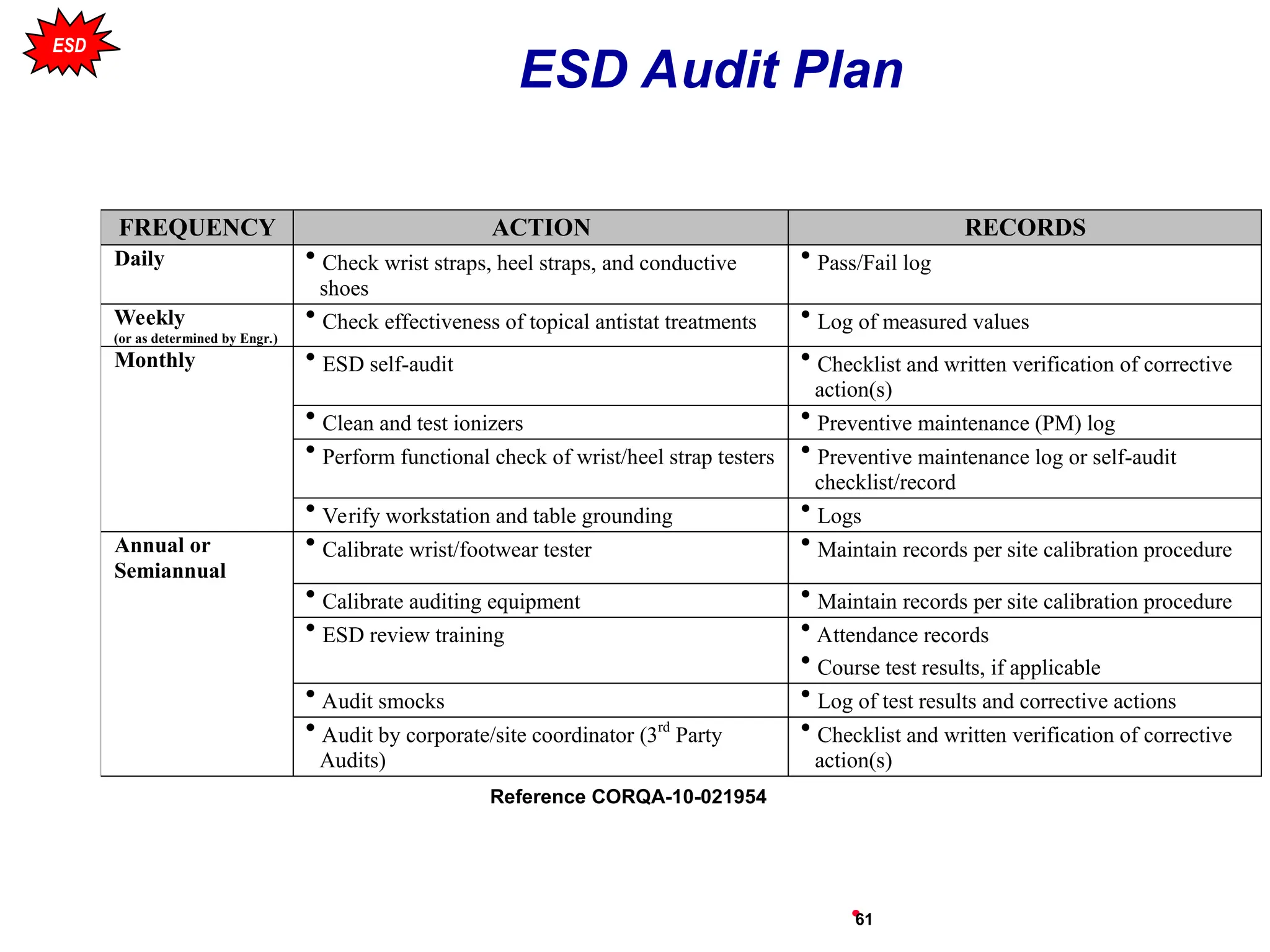

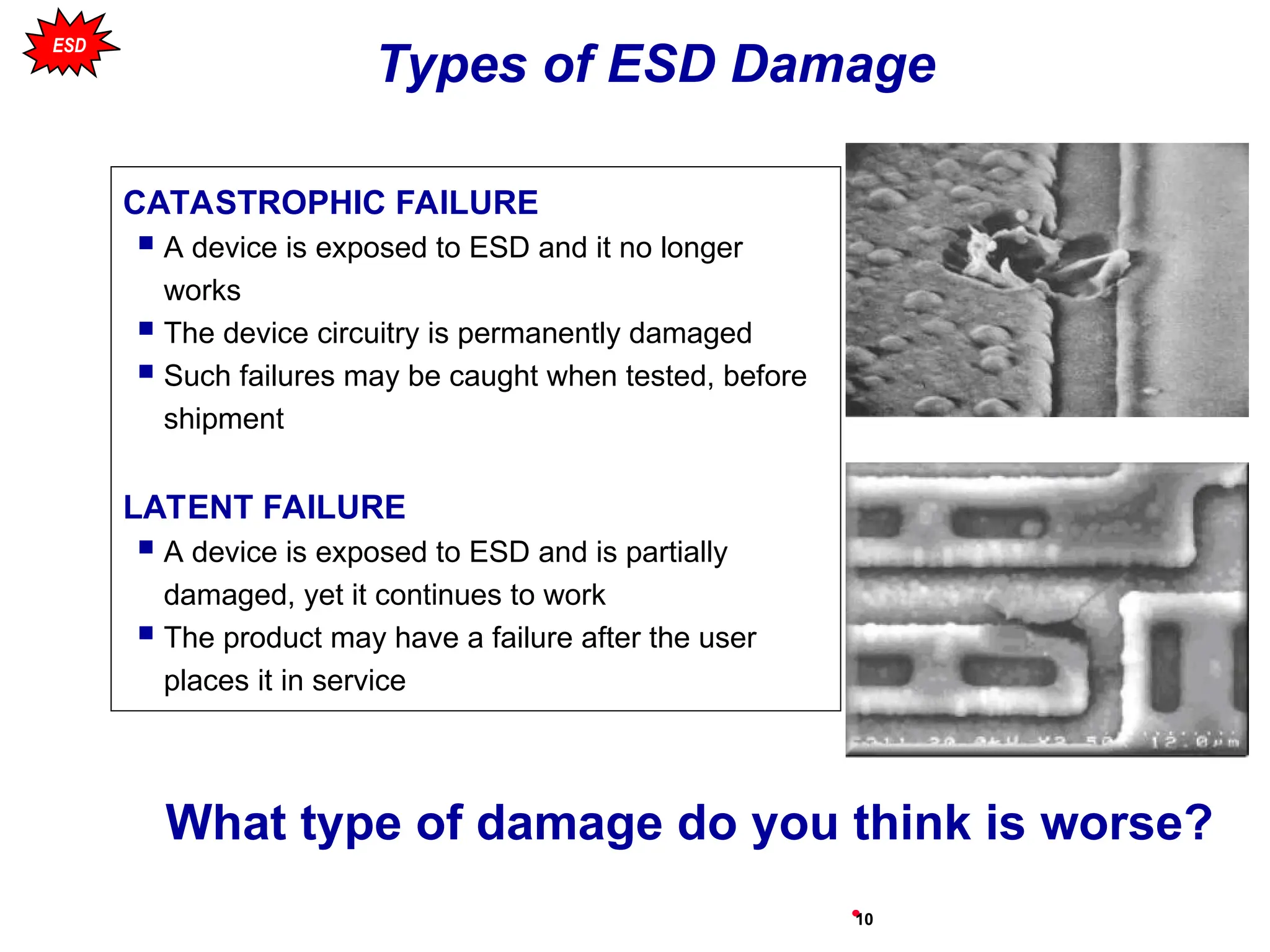

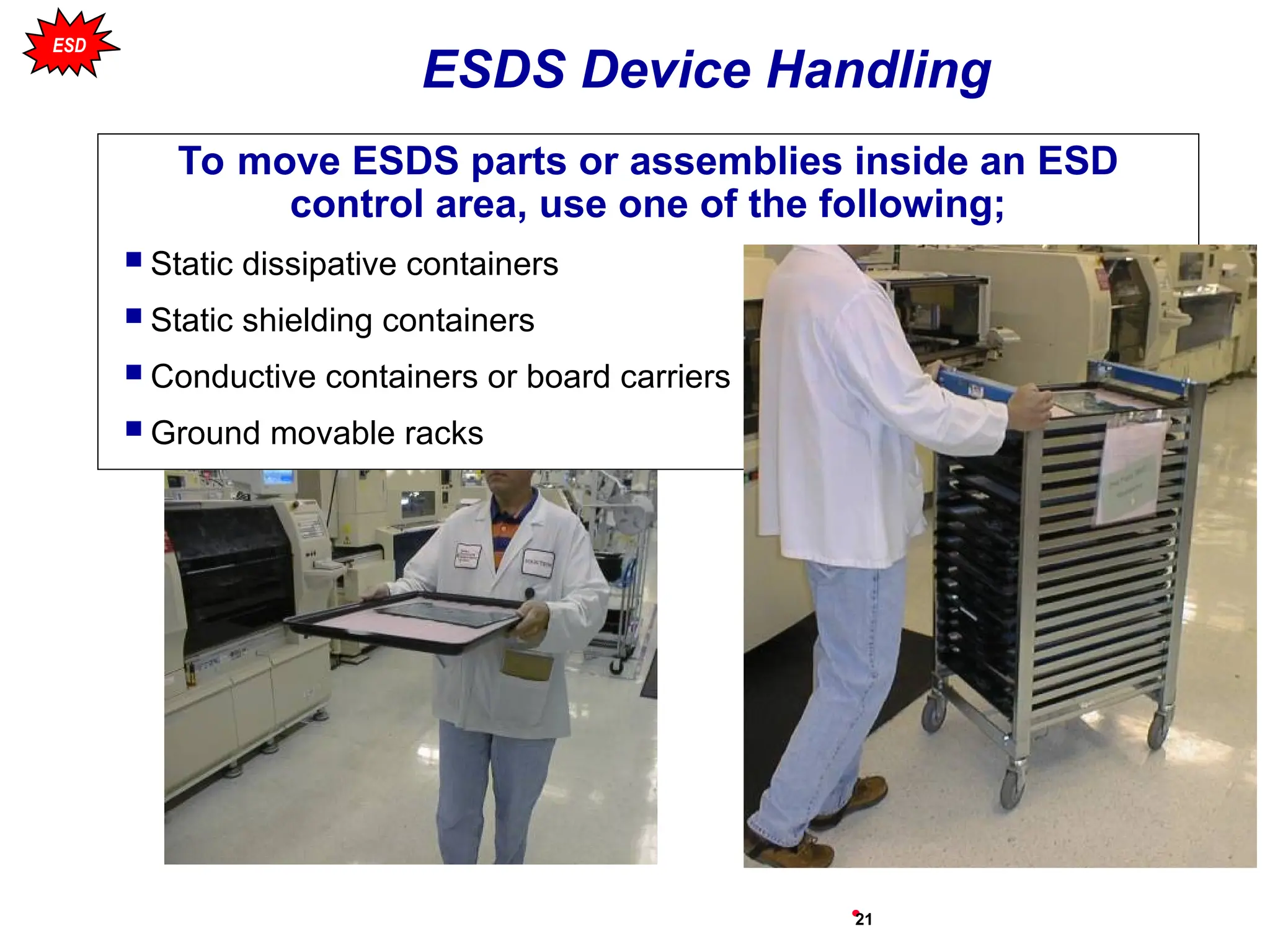

Prevention & Controlling

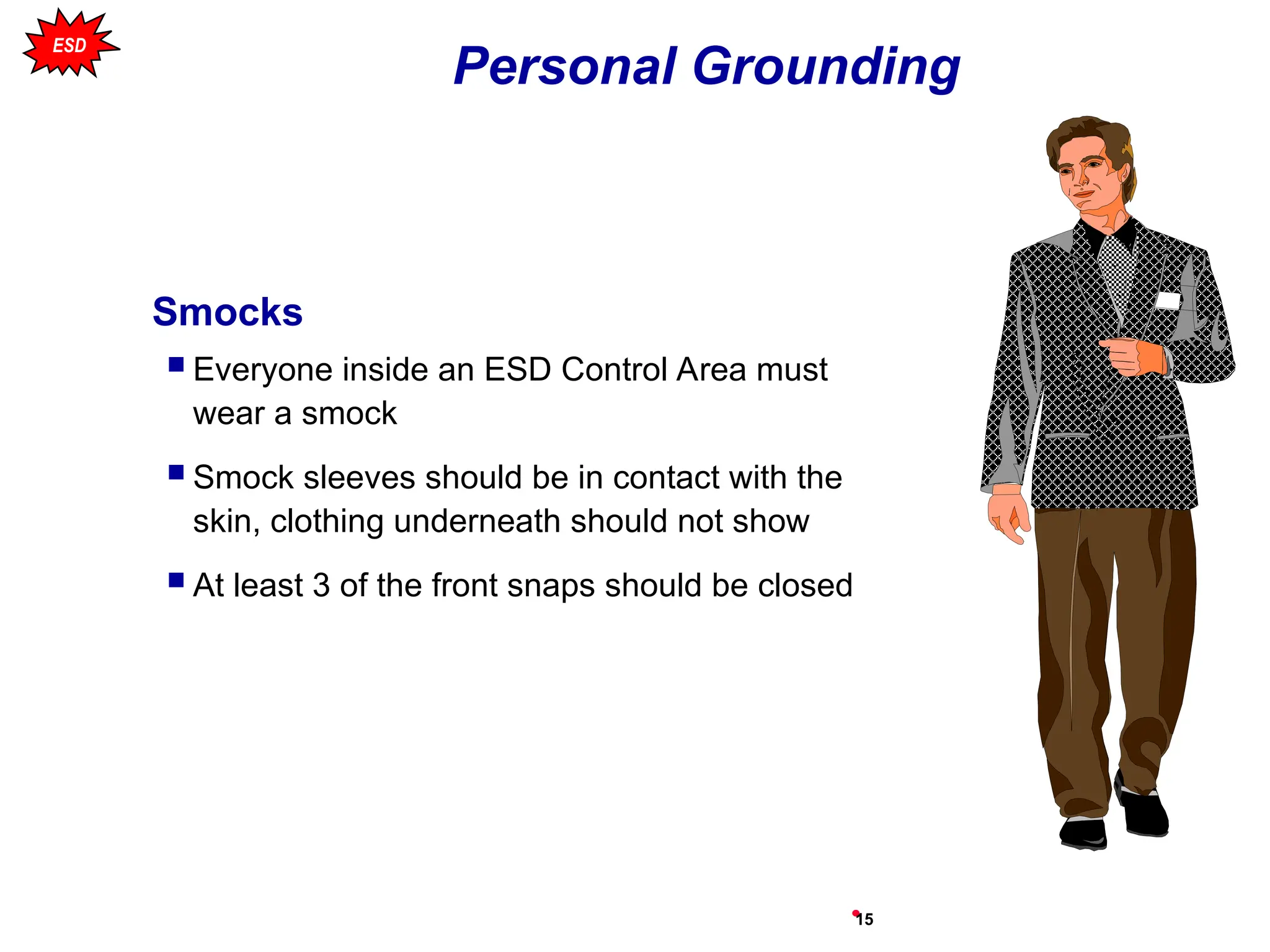

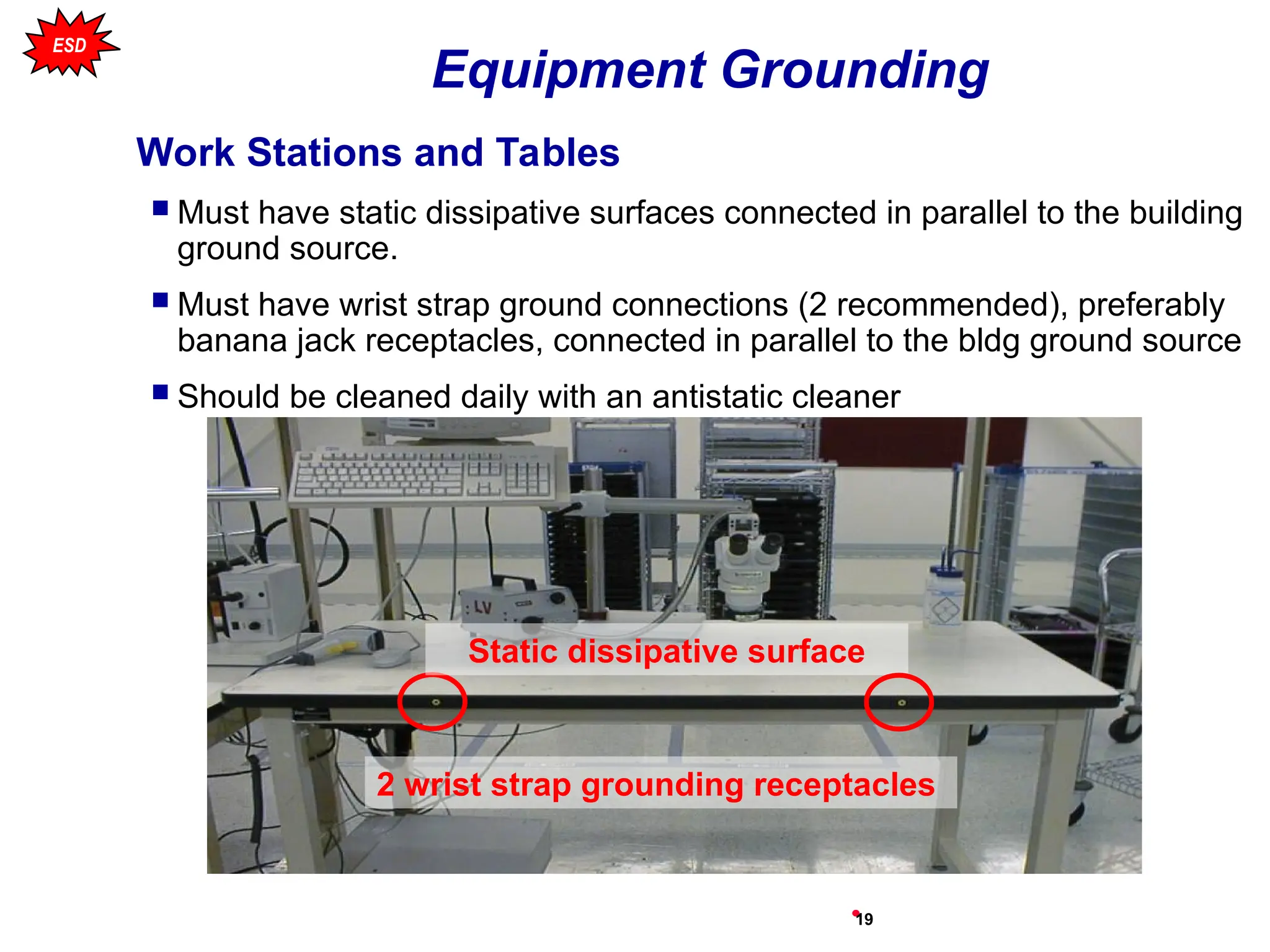

Workstation grounding

Work surface where Electrostatic sensitive device is being handled must be

properly grounded to the common grounding point.

Each work station must have a separate grounding point. [ connecting one

work surface ground to another is not recommended ]

The use of a 1M ohm resister in series during grounding is recommended

due to safety reason . [ Some standard do not require this ]

Static dissipative

tabletop

Grounding

Point

Resistance

1 Mohm

Wrist strap

grounding point](https://image.slidesharecdn.com/esdtraining-240821061426-32645bd4/75/Electro-static-discharge-ESD-Safety-awareness-training-53-2048.jpg)

![ESD

60

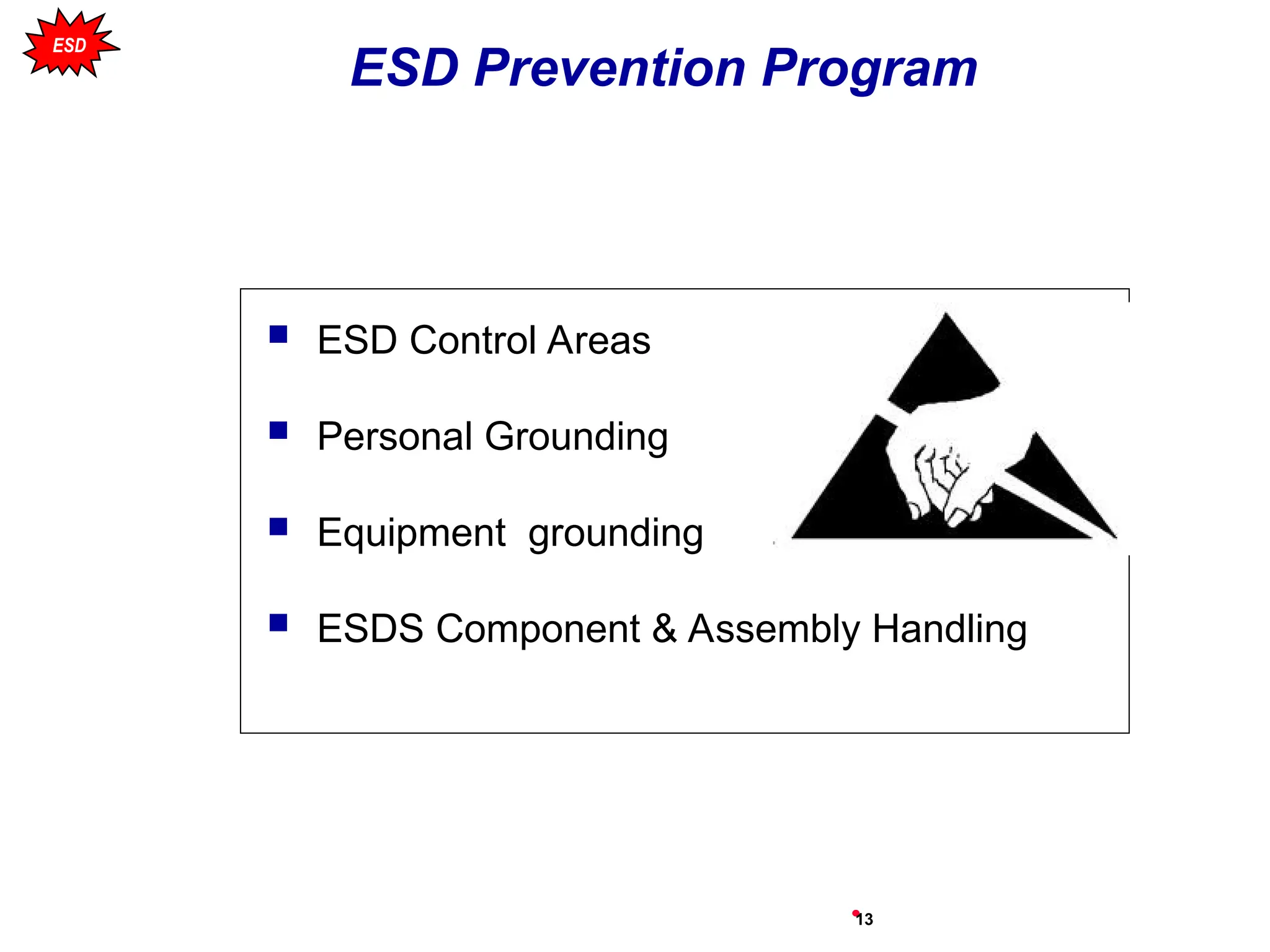

Prevention & Controlling

Humidity

Humidity contains water vapor in the air which reduce the charge

generation.

As the presence of moisture in the air is increased, electrons are better able

to discharge safely into the air instead of another object.

It also makes some surface to be become conductive due to moisture

observation [exp : cold countries have higher concern on paper charging

compare to Hot countries]

As humidity goes higher lower the charge and as lower the humidity higher

the charge .

The recommended humidity range by ANSI is 40% to 60% RH .](https://image.slidesharecdn.com/esdtraining-240821061426-32645bd4/75/Electro-static-discharge-ESD-Safety-awareness-training-60-2048.jpg)