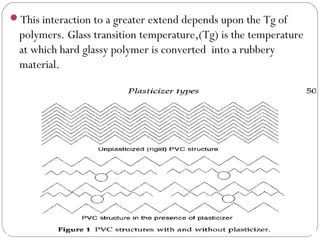

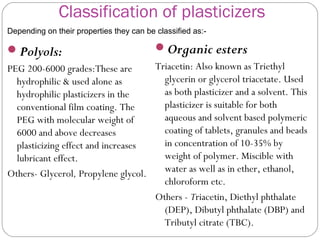

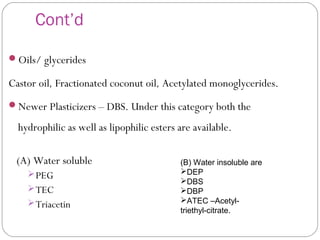

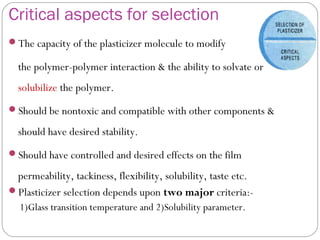

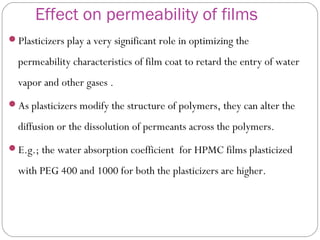

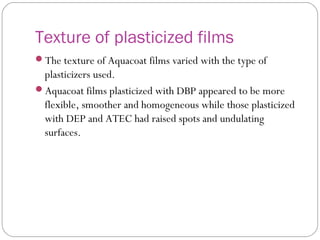

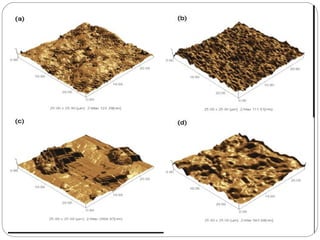

The document discusses plasticizers, additives that enhance the flexibility and fluidity of polymer materials, particularly in pharmaceutical film formulations. It covers the mechanism of action, classification, ideal properties, effects on permeability and mechanical properties, and limitations associated with their use. The selection of an appropriate plasticizer is critical for optimizing coated dosage forms while balancing desired and undesired effects.