1. Plasticizers increase the plasticity and flexibility of polymers by interposing between polymer strands and preventing reformation of chain interactions. This modifies the tertiary structure of polymers into a more porous and flexible state.

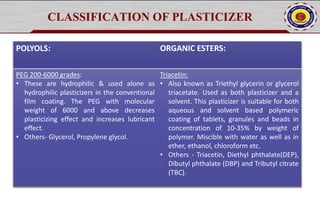

2. Common plasticizers include polyols like PEG and esters like phthalates and citrates. Plasticizers decrease tensile strength, increase film elongation, and reduce glass transition temperature of films.

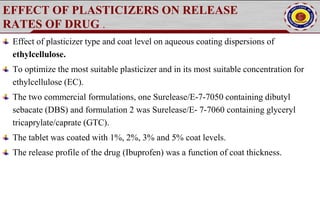

3. The effect of plasticizers on drug release depends on coat level and plasticizer type. Some plasticizers like glyceryl tricaprylate/caprate produce non-Fickian release while dibutyl sebacate produces zero-order release.