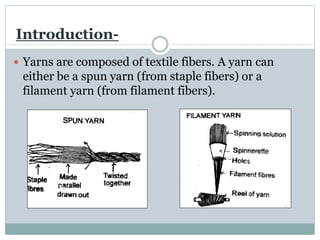

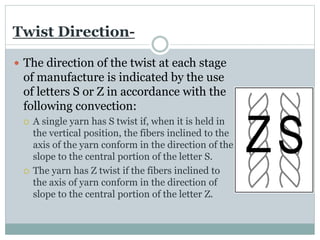

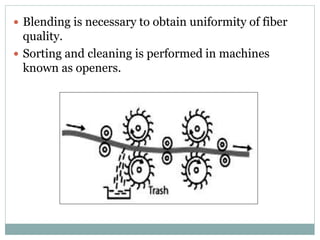

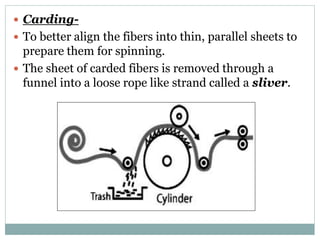

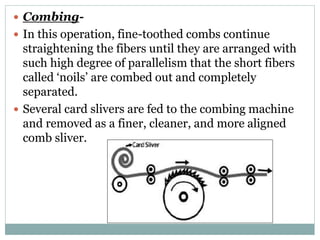

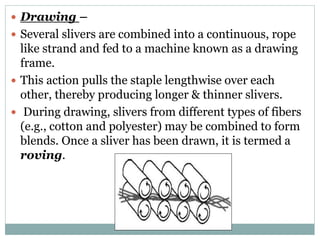

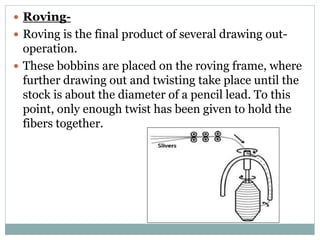

Yarn is composed of fibers that are twisted together. The amount of twist is measured in turns per inch and can be low, medium, or high. Twist direction is indicated by S or Z letters. Natural fiber yarns are made through processes like opening, carding, combing, drawing and roving to align fibers, then ring spinning draws, twists and winds them into yarn. Man-made fibers are extruded through spinnerets as filaments and solidified, then converted into yarns using wet, melt or dry spinning.