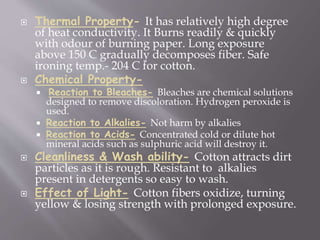

Textile fibers are the basic building blocks used to manufacture fabric. They come in two main lengths - staple fibers which are short, and filament fibers which are very long. Fibers also come from natural, regenerated, or synthetic sources. Cotton is a widely used natural staple fiber obtained from plant seeds. It has good strength and absorbency but is relatively inelastic. Cotton burns readily with the smell of burning paper and is damaged by concentrated acids.