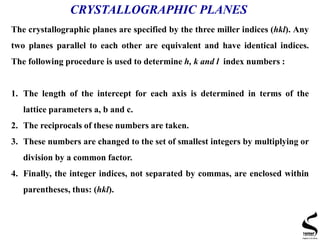

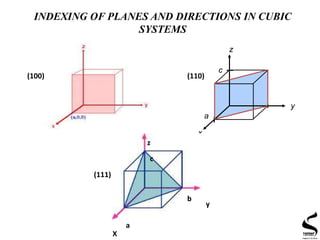

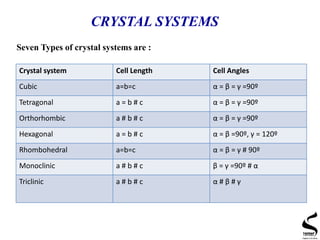

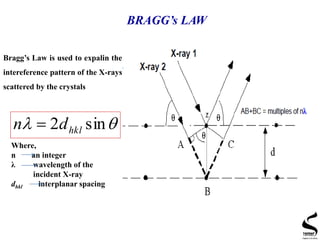

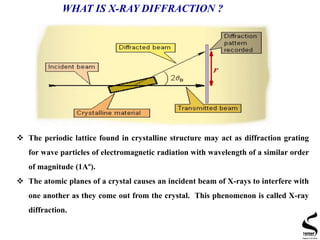

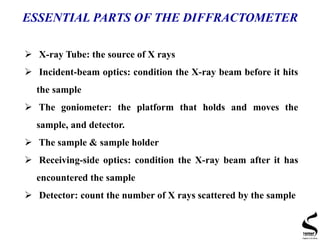

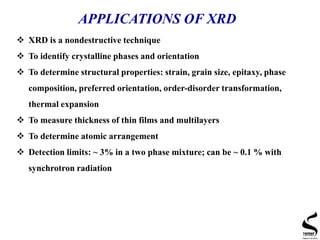

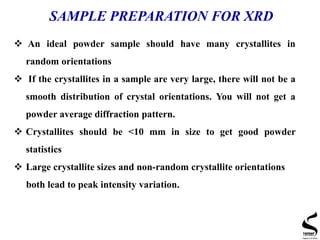

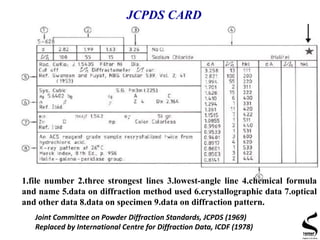

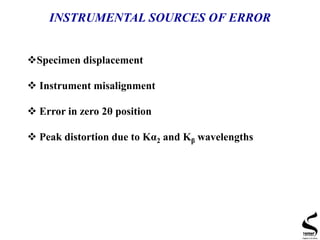

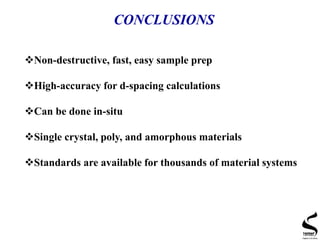

X-ray diffraction is a technique used to analyze the crystal structure of materials. It works by firing x-rays at a crystalline sample and measuring the angles and intensities of the x-rays that are diffracted. The document discusses key concepts like Bragg's law, unit cells, miller indices, and how x-ray diffraction is used to determine properties like phase identification, crystallite size, strain, and lattice parameters. It also outlines the basic components of an x-ray diffractometer and sources of error in measurements.

![CRSYSTALLOGRAPHIC DIRECTIONS

A crystallographic direction is defined as the line between two vectors. The

following steps are utilized in the determination of the three dimensional

indices:

1. A vector of conventional length is positioned such that it passes through

the origin of the coordinate system.

2. The length of the vector projection on each of the three axes is

determined; these are measured in terms of the unit cell dimensions a,b

and c.

3. These three numbers are multiplied or divided by a common factor to

reduce them to the smallest integer values.

4. The three indices are enclosed in square brackets :

[uvw]. The u, v and w integers

correspond to the reduced projections along

the x, y and z axes, respectively](https://image.slidesharecdn.com/xrdtechniqueandapplication-151216181023/85/XRD-principle-and-application-4-320.jpg)