This document provides an overview of x-ray diffraction principles and practices. It begins with an introduction to materials characterization and the importance of x-ray diffraction. It then covers the basics of diffraction and Bragg's law. The document discusses different x-ray diffraction methods and techniques for analyzing crystal structure, phase, texture, stress, and particle size. It provides examples of analyzing diffraction patterns from single and multiple phases. Finally, it touches on concepts like broadening, texture, and pole figures.

![Texture

Fiber Texture

A particular direction [uvw] for all grains is more or less parallel to

the wire or fiber axis

e.g. [111] fiber texture in Al cold drawn wire

Double axis is also possible

Example: [111] and [100] fiber textures in Cu wire

Sheet Texture

Most of the grains are oriented with a certain crystallographic plane

(hkl) roughly parallel to the sheet surface and certain direction [uvw]

parallel to the rolling direction

Notation: (hkl)[uvw]](https://image.slidesharecdn.com/termprojectsaxs-230209084404-1883ec68/75/Small-angle-X-ray-Diffraction-43-2048.jpg)

![Texture in materials

[uvw] i.e. perpendicular to

the surface of all grains is

parallel to a direction [uvw]

Also, if the direction [u1v1w1]

is parallel for all regions, the

structure is like a single

crystal

However, the direction [u1v1w1]

is not aligned for all regions,

the structure is like a mosaic

structure, also called as

Mosaic Texture](https://image.slidesharecdn.com/termprojectsaxs-230209084404-1883ec68/75/Small-angle-X-ray-Diffraction-44-2048.jpg)

![Degree of orientation

Substrate

Film

Side view

[uvw] corresponding

to planes parallel to

the surface

But what if the planes when looked from top have random orientation?

Top view](https://image.slidesharecdn.com/termprojectsaxs-230209084404-1883ec68/75/Small-angle-X-ray-Diffraction-45-2048.jpg)

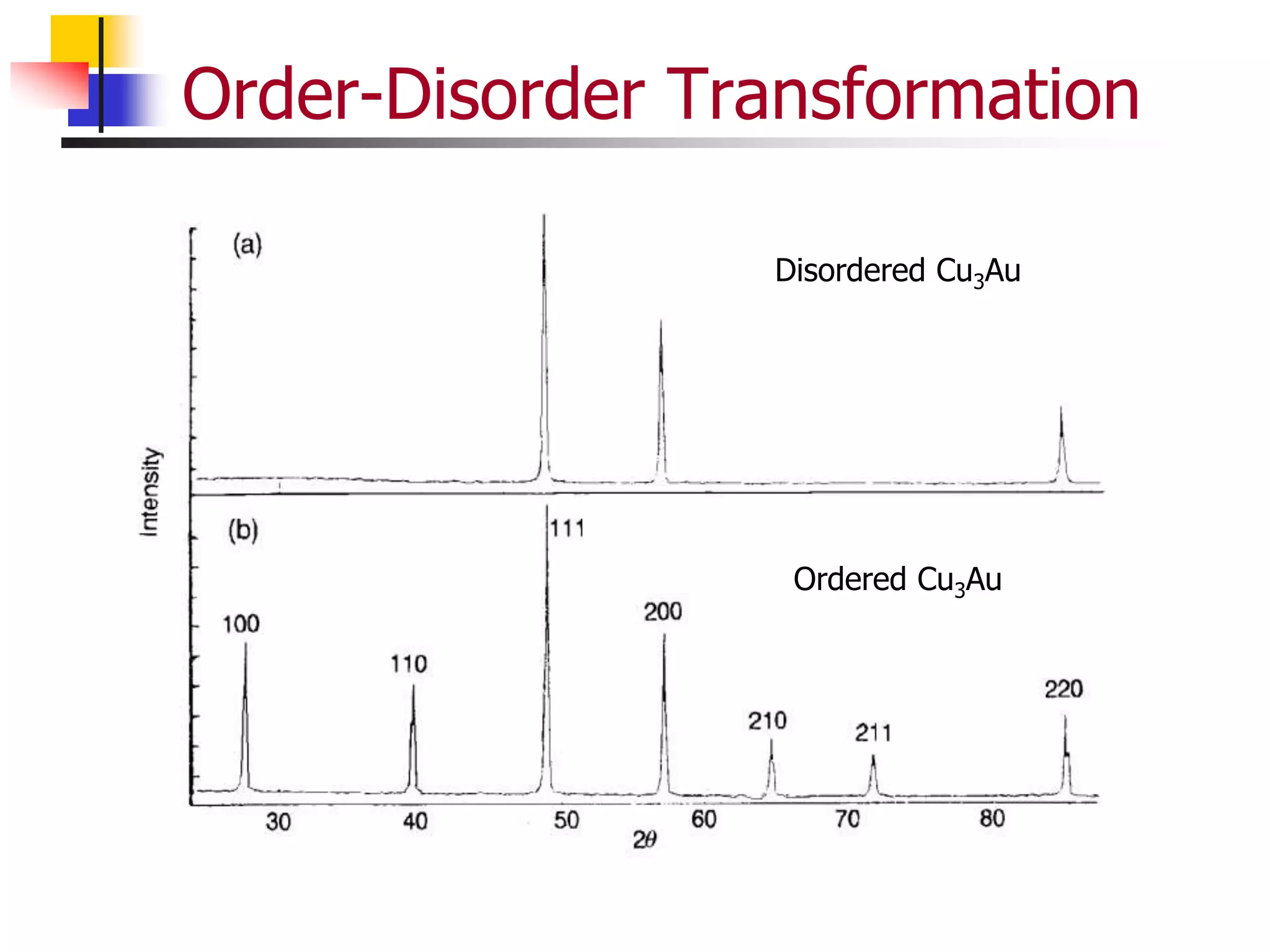

![Order Disorder Transformation

Structure factor is dependent on the presence

of order or disorder within a material.

Complete Disorder

Example: AB with A and B atoms

randomly distributed in the lattice

Lattice positions: (000) and (½ ½ ½)

Atomic scattering factor

favj= ½ (fA+fB)

Structure Factor, F, is given by

F = Σf exp[2i (hu+kv+lw)]

= favj [1+e( i (h+k+l))]

= 2. favj when h+k+l is even

= 0 when h+k+l is odd

The expected pattern is like a BCC crystal

A

B](https://image.slidesharecdn.com/termprojectsaxs-230209084404-1883ec68/75/Small-angle-X-ray-Diffraction-49-2048.jpg)

![Order Disorder Transformation

Complete Order

Example: AB with A at (000) and B at (½ ½ ½)

Structure Factor, F, is given by

F = fA e[2i (h.0+k.0+l.0)]+ fA e[2i (h. ½+k. ½+l. ½)]

= fA+fB when h+k+l is even

= fA-fB when h+k+l is odd

The expected pattern is not like a BCC crystal,

rather like a simple cubic crystal where all the

reflections are present.

Extra reflections present are called as

superlattice reflections

A

B](https://image.slidesharecdn.com/termprojectsaxs-230209084404-1883ec68/75/Small-angle-X-ray-Diffraction-50-2048.jpg)