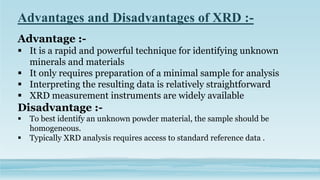

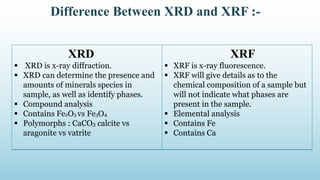

XRD and XRF are analytical techniques used to characterize materials. XRD determines the crystalline structure of materials by measuring diffraction patterns of X-rays. It can identify phases and minerals present in a sample. XRF determines the elemental composition of materials by detecting X-ray fluorescence emitted from a sample. Both techniques are non-destructive and provide qualitative and quantitative analysis of materials' composition and structure.

![XRD And XRF

PRESENTED BY :-

DR. REKHA RAM

P.G. 1ST YEAR

Guided BY :-

DR. AVADHESH KUMAR BHATT

PROFESSOR & HOD

M.D. [Ayu.]

POST GRADUATE DEPARTMENT OF

RAS SHASTRA AND BHAISHAJYA KALPANA

M.M.M. GOVERNMENT AYURVED COLLEGE,

UDAIPUR (RAJ.)](https://image.slidesharecdn.com/xrdandxrf2-230520050247-e367df38/85/XRD-And-XRF2-pptx-1-320.jpg)