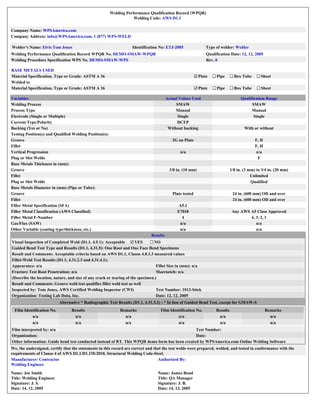

This document is a Welding Performance Qualification Record (WPQR) that qualifies a welder according to the AWS D1.1 welding code. It details the welding procedure used including the base metals, welding process, filler metal, welding positions qualified, and test results. The welder, Elvis Tom Jones, used SMAW with E7018 electrode to weld ASTM A36 steel plate in the flat and horizontal positions. Visual and guided bend tests of the welds met the acceptance criteria of AWS D1.1, qualifying the welding procedure and welder.