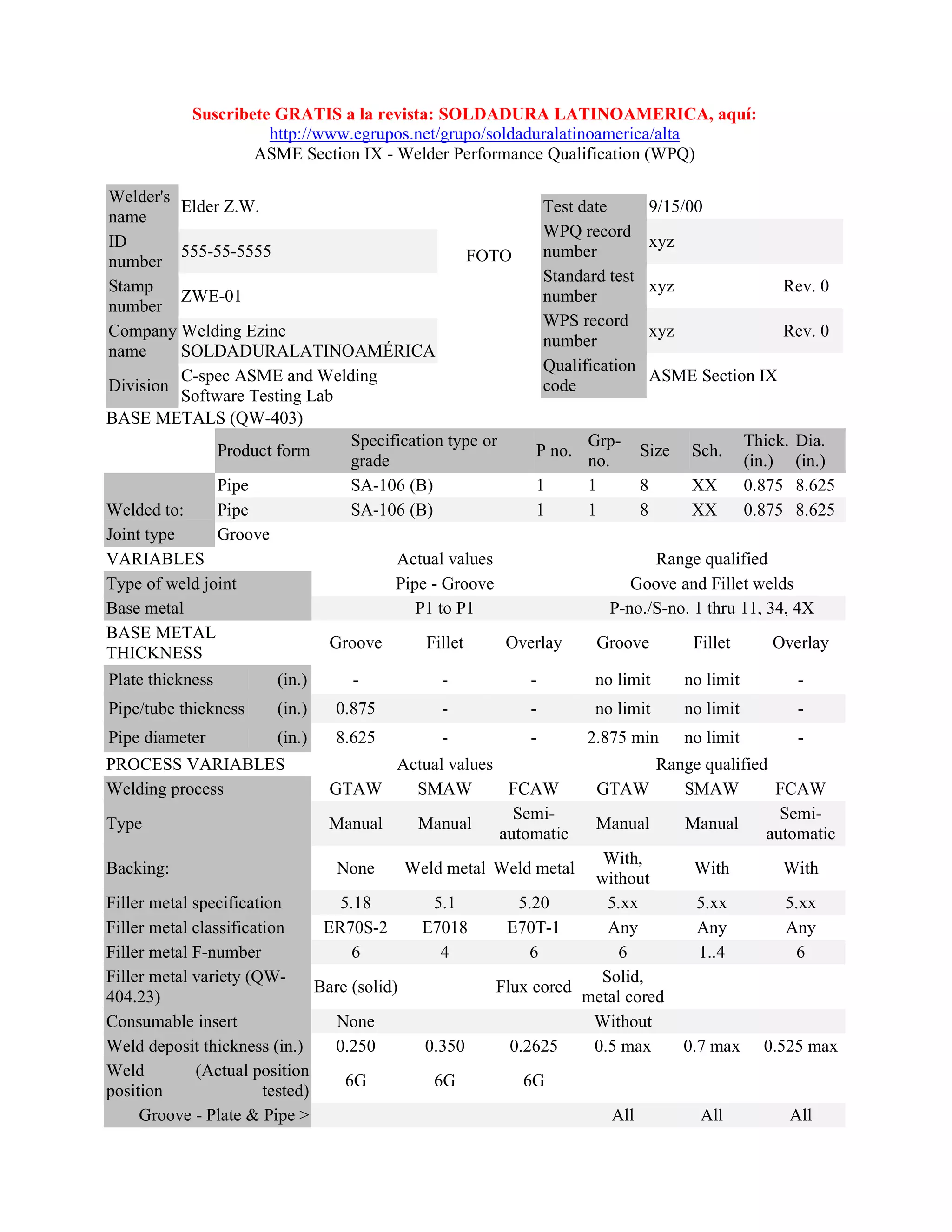

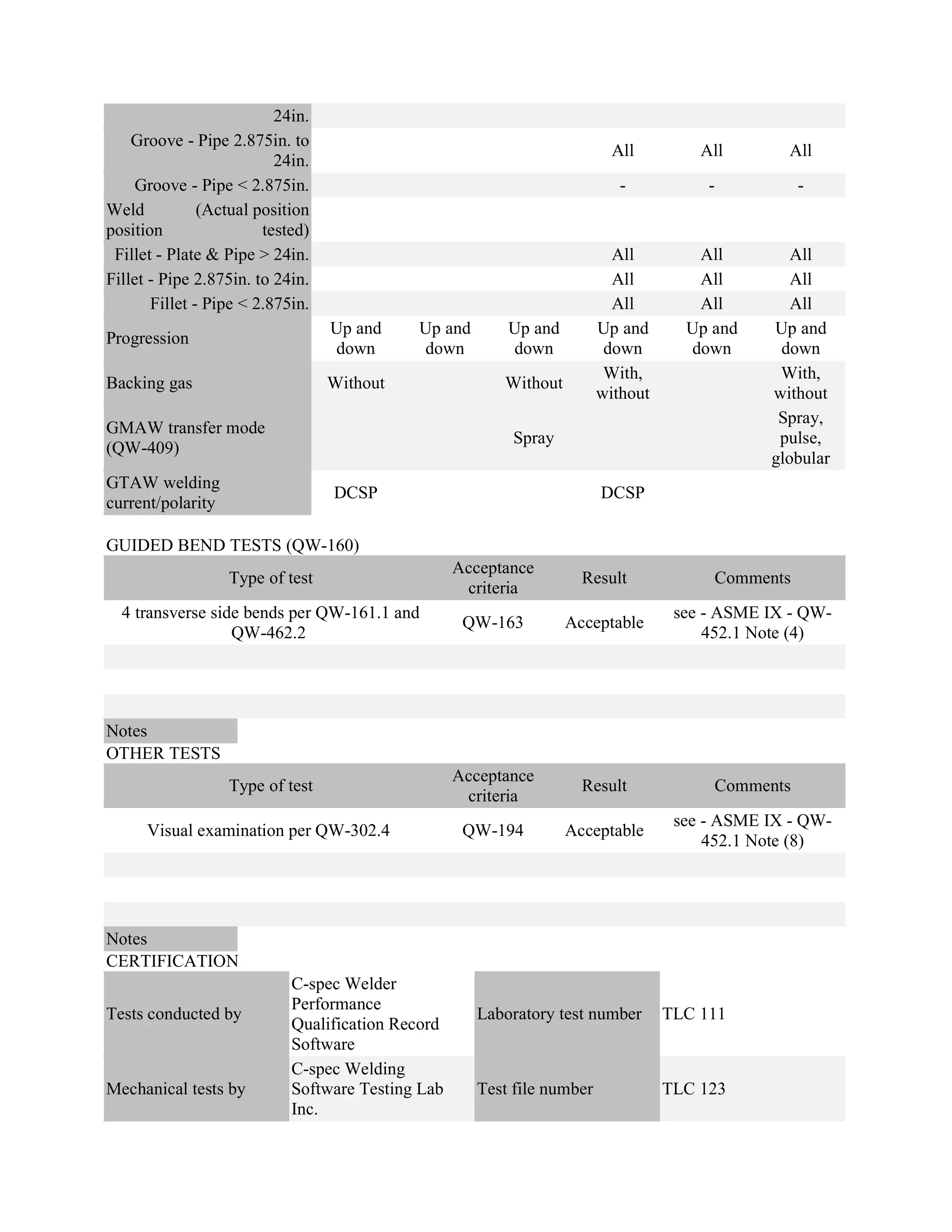

This document is a welder performance qualification record that certifies welder Elder Z.W. It summarizes the tests conducted including:

- Welding process used was gas tungsten arc welding in the 6G position.

- Materials welded were SA-106 Grade B carbon steel pipes 0.875 inches thick.

- Visual and guided bend tests were conducted and met the acceptance criteria of ASME Section IX.