The document provides an overview of the typical duties of welding inspectors, which include assisting with quality control activities to ensure welded items meet specifications. Welding inspectors must understand quality control procedures and have sound welding technology knowledge. Visual inspection is a key non-destructive examination technique used by inspectors, along with other methods like surface crack detection and volumetric inspection of butt welds depending on application. Standards provide acceptance criteria for inspections, and ISO 17637 provides basic requirements for visual inspections.

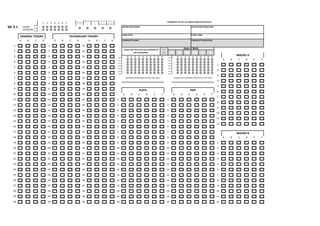

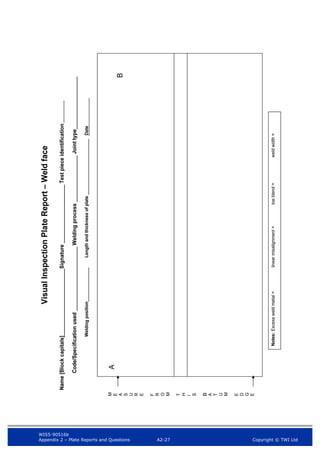

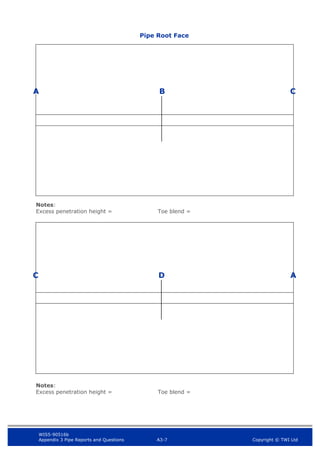

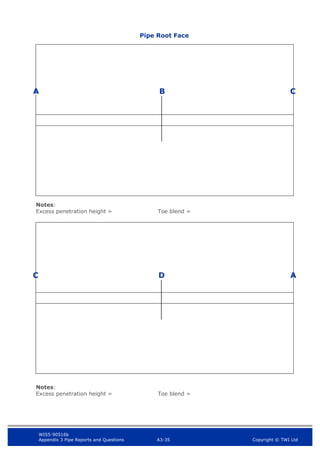

![WIS5-90516b

Appendix 3 Pipe Reports and Questions A3-6 Copyright © TWI Ltd

Visual Inspection Pipe Report

Name [Block capitals]

Signature Pipe Ident#

Code/Specification used Welding Process Joint type

Welding position OutsideØ and Thickness Date

Weld face

A B

C D

Notes:

Excess weld metal height = Misalignment = Weld width = Toe blend =

Notes:

Excess weld metal height = Misalignment = Toe blend = Weld width =

A

C](https://image.slidesharecdn.com/mainbookcswip31weldinginspectorwi-221218121938-b54ec8e9/85/Main_book_CSWIP_3_1_Welding_Inspector_WI-pdf-607-320.jpg)

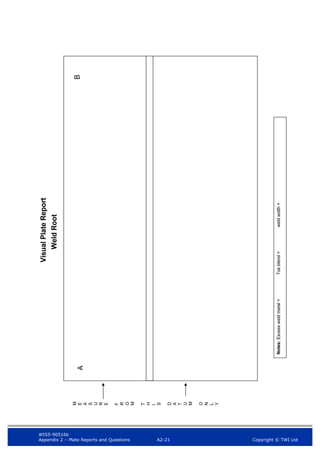

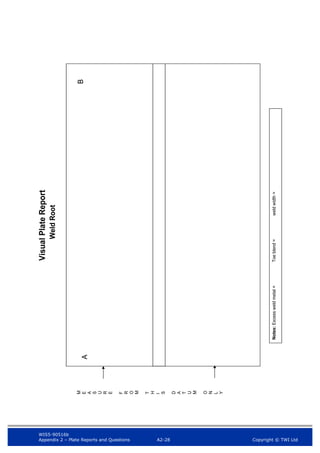

![WIS5-90516b

Appendix 3 Pipe Reports and Questions A3-13 Copyright © TWI Ltd

Visual Inspection Pipe Report

Name [Block capitals]

Signature Pipe Ident#

Code/Specification used Welding Process Joint type

Welding position OutsideØ and Thickness Date

Weld face

A B

C D

Notes:

Excess weld metal height = Misalignment = Weld width = Toe blend =

Notes:

Excess weld metal height = Misalignment = Toe blend = Weld width =

A

C](https://image.slidesharecdn.com/mainbookcswip31weldinginspectorwi-221218121938-b54ec8e9/85/Main_book_CSWIP_3_1_Welding_Inspector_WI-pdf-619-320.jpg)

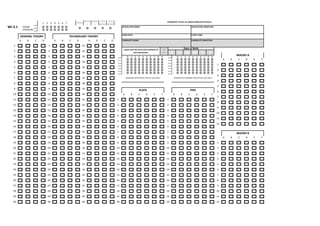

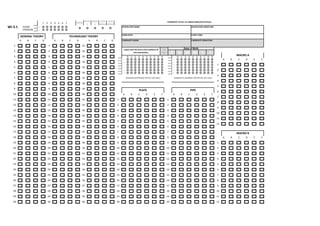

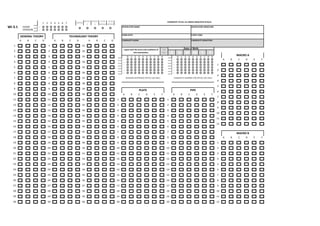

![WIS5-90516b

Appendix 3 Pipe Reports and Questions A3-20 Copyright © TWI Ltd

Visual Inspection Pipe Report

Name [Block capitals]

Signature Pipe Ident#

Code/Specification used Welding Process Joint type

Welding position OutsideØ and Thickness Date

Weld face

A B

C D

Notes:

Excess weld metal height = Misalignment = Weld width = Toe blend =

Notes:

Excess weld metal height = Misalignment = Toe blend = Weld width =

A

C](https://image.slidesharecdn.com/mainbookcswip31weldinginspectorwi-221218121938-b54ec8e9/85/Main_book_CSWIP_3_1_Welding_Inspector_WI-pdf-631-320.jpg)

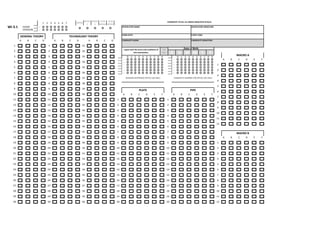

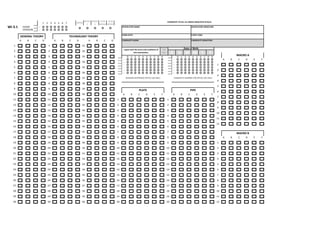

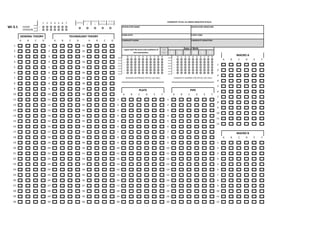

![WIS5-90516b

Appendix 3 Pipe Reports and Questions A3-27 Copyright © TWI Ltd

Visual Inspection Pipe Report

Name [Block capitals]

Signature Pipe Ident#

Code/Specification used Welding Process Joint type

Welding position OutsideØ and Thickness Date

Weld face

A B

C D

Notes:

Excess weld metal height = Misalignment = Weld width = Toe blend =

Notes:

Excess weld metal height = Misalignment = Toe blend = Weld width =

A

C](https://image.slidesharecdn.com/mainbookcswip31weldinginspectorwi-221218121938-b54ec8e9/85/Main_book_CSWIP_3_1_Welding_Inspector_WI-pdf-643-320.jpg)

![WIS5-90516b

Appendix 3 Pipe Reports and Questions A3-34 Copyright © TWI Ltd

Visual Inspection Pipe Report

Name [Block capitals]

Signature Pipe Ident#

Code/Specification used Welding Process Joint type

Welding position OutsideØ and Thickness Date

Weld face

A B

C D

Notes:

Excess weld metal height = Misalignment = Weld width = Toe blend =

Notes:

Excess weld metal height = Misalignment = Toe blend = Weld width =

A

C](https://image.slidesharecdn.com/mainbookcswip31weldinginspectorwi-221218121938-b54ec8e9/85/Main_book_CSWIP_3_1_Welding_Inspector_WI-pdf-655-320.jpg)

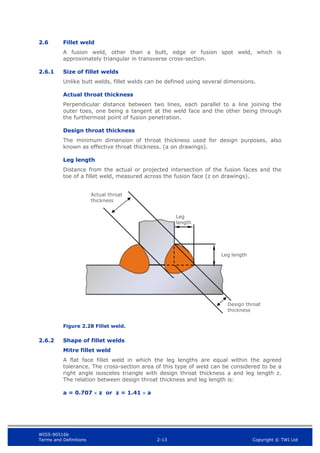

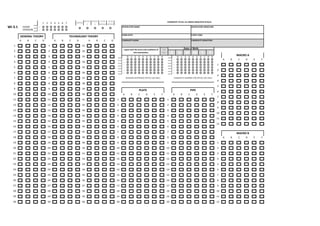

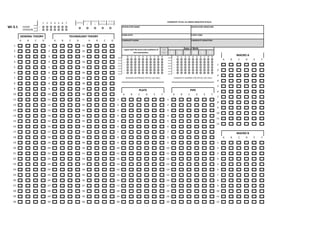

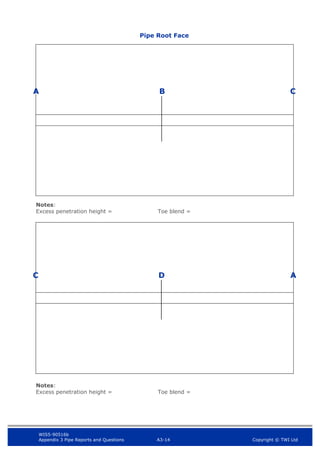

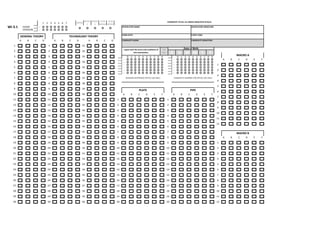

![Copyright © TWI Ltd

Practical Pipe Inspection

Copyright © TWI Ltd

When these presentation have been completed

you will have a greater understanding of the

examination requirement and how to identify

and plot weld defects around real life welds and

the classroom specimens on which you will be

examined.

Practical Sessions Objective

Copyright © TWI Ltd

Pipe Inspection

Copyright © TWI Ltd

HI-LO

Single

Purpose

Welding

Gauge

1

2

3

4

5

6

Root gap

dimension

Internal

alignment

Hi-Low and Root Gap Measurements

Copyright © TWI Ltd

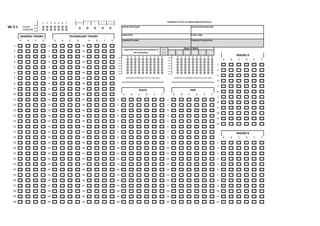

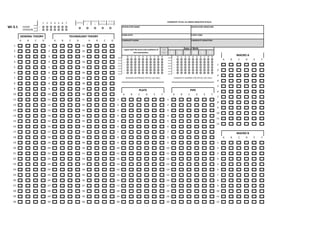

Pipe Inspection Examination

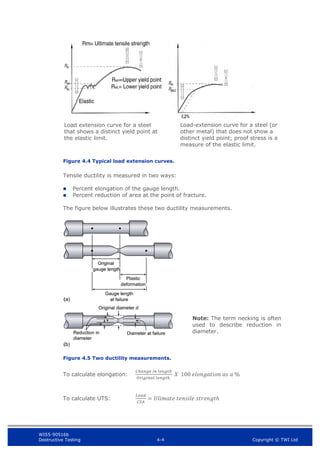

After you have observed an imperfection and

determined its type, you must be able to take

measurements and complete the thumb print

report sketch.

The first thumb print report sketch should be in

the form of a repair map of the weld. (ie all

observations are Identified sized and located).

The thumb print report sketch used in CSWIP

exam will look like the following example.

The thumb print is to used in conjunction with

the multiple choice questions during the

examination .

Pipe Inspection Examination

Copyright © TWI Ltd

EXAMPLE PIPE REPORT

Name: [Block capitals] ….............................. Signature: ……………….

Date…………………….

Code/Specification used: …………………… Welding process: ……………… Joint type: …………….

Welding position: …………………. Outside Dia & thickness …………… Date ……………………

WELD FACE

C

B

A

98

Arc Strike

20 15

Lack of side

wall fusion

90 10

Undercut

>1.0 mm

140 8

Lack of side

wall fusion

180

46

Under fill

40 12

Under fill

60 5

Slag

inclusion

NOTES:

A

D

C

12

0

15

Slag

2

5

Arc Strike

3

8

8

Lack of side wall fusion

/ incomplete fill

Excess Weld Metal Height = Misalignment = Weld Width = Toe Blend =

NOTES:

Excess Weld Metal Height = Misalignment = Weld Width = Toe Blend =

Pipe Inspection Examination

A3-1](https://image.slidesharecdn.com/mainbookcswip31weldinginspectorwi-221218121938-b54ec8e9/85/Main_book_CSWIP_3_1_Welding_Inspector_WI-pdf-663-320.jpg)