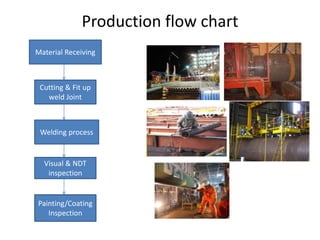

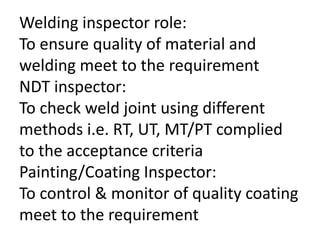

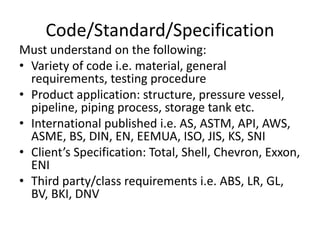

This document provides an overview of Rahman Suwandhi's role and responsibilities as a Quality/Welding Engineer conducting inspections during offshore pipeline and platform installations. It outlines the required qualifications and certifications, describes the production and inspection workflow, and details the various inspection activities conducted, including material, welding, non-destructive testing (NDT), and painting/coating inspections. Specific areas of inspection focus are ensuring materials and welding meet requirements, using NDT methods to check weld joints, and controlling and monitoring coating quality. Relevant quality documents, codes/standards, inspection variables, and acceptance criteria are also summarized.