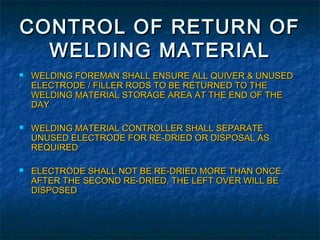

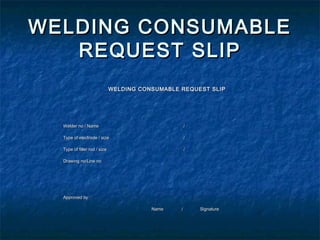

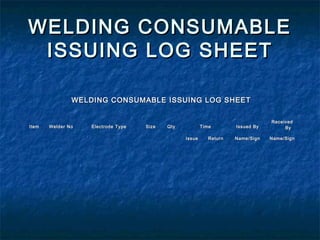

This document outlines the controls for welding consumables at the Dung Quat Refinery Project. It discusses responsibilities for monitoring consumables, proper storage according to manufacturer recommendations, drying and keeping electrodes warm as specified, and issuing electrodes only with approved request slips. Welding foremen must ensure unused electrodes are returned daily and the material controller will separate for re-drying or disposal. Logs are maintained to record baking, issuing, and returns of welding materials. The goal is to provide welders with quality electrodes to achieve high quality welds and safe plant operations.