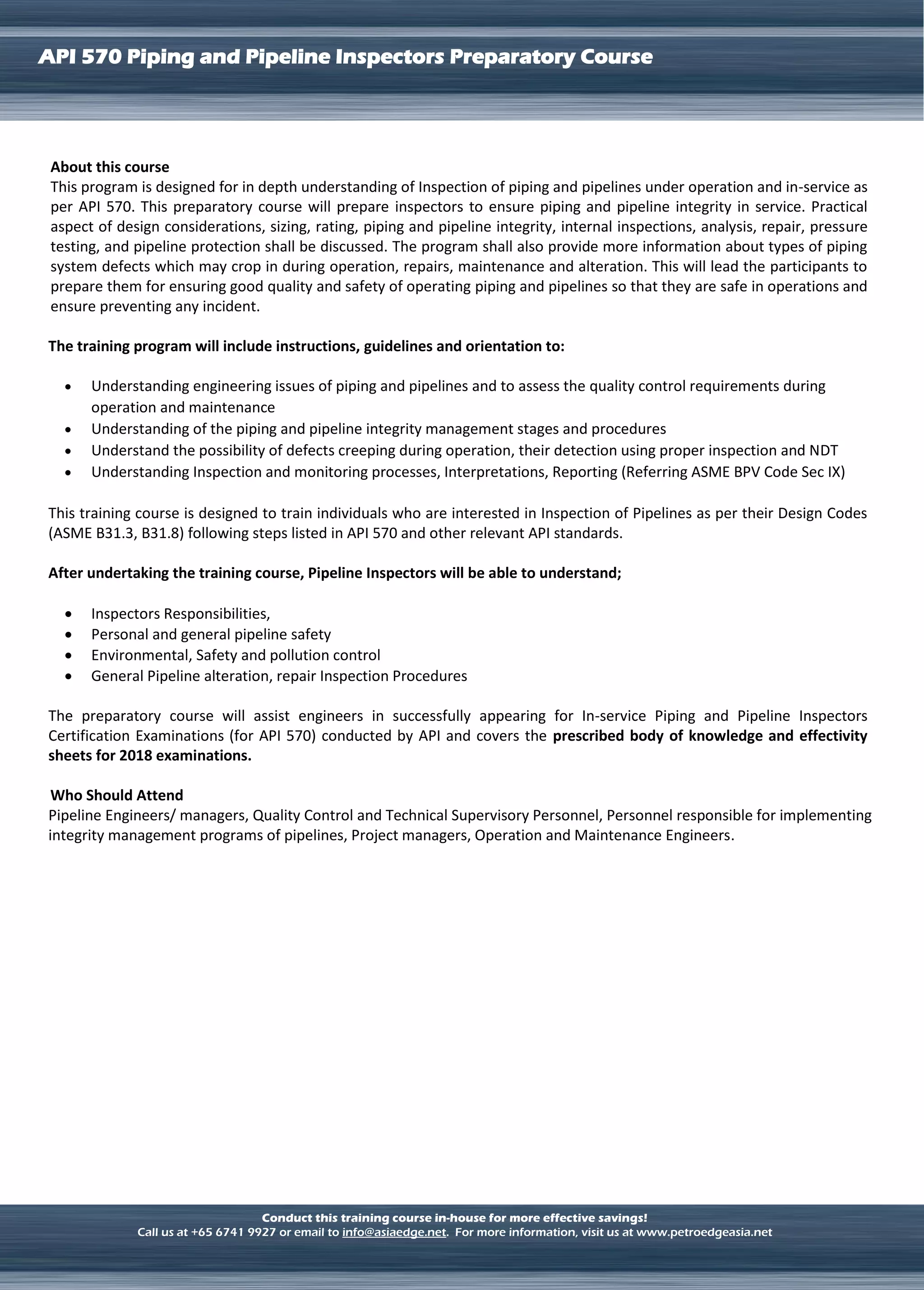

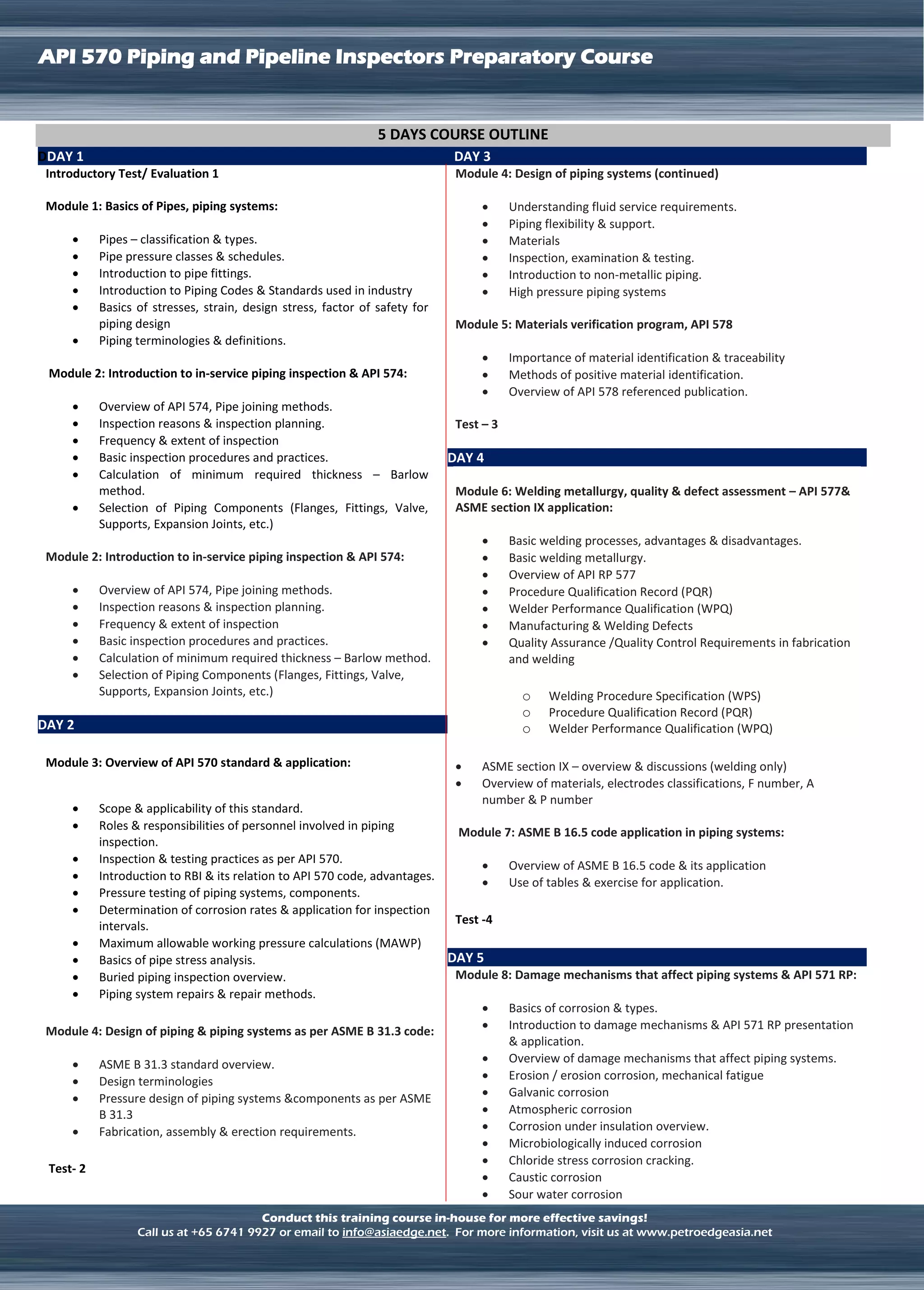

The document outlines a preparatory course for API 570 piping and pipeline inspectors, led by Ganapathy Balasubramaniam, who has over 30 years of experience in the industry. The course covers various aspects of piping inspection, integrity management, defects, and includes practical applications in line with relevant codes and standards. It is aimed at professionals involved in pipeline engineering and quality control, preparing them for certification examinations and enhancing their skills in maintaining pipeline safety and integrity.