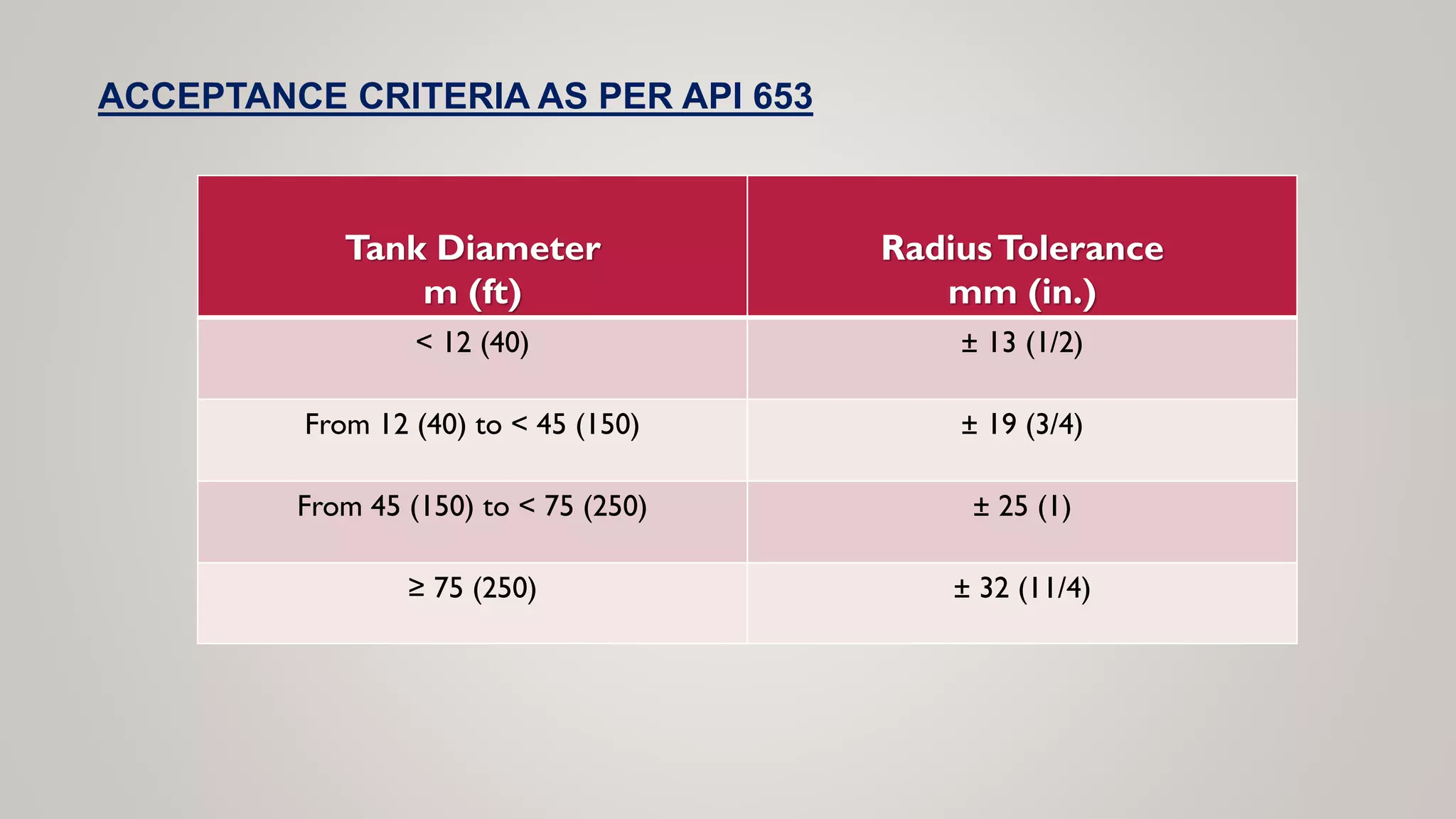

The document discusses methods for measuring the plumbness and roundness of storage tank shells during construction and maintenance. Plumbness is measured using a total station to determine the verticality of each shell course, while roundness is measured to check how circular each course is. Measurements are taken at regular intervals and positions around the tank circumference and shell height. The document provides acceptance criteria from API standards, specifying maximum allowable deviations for plumbness and roundness based on tank size.