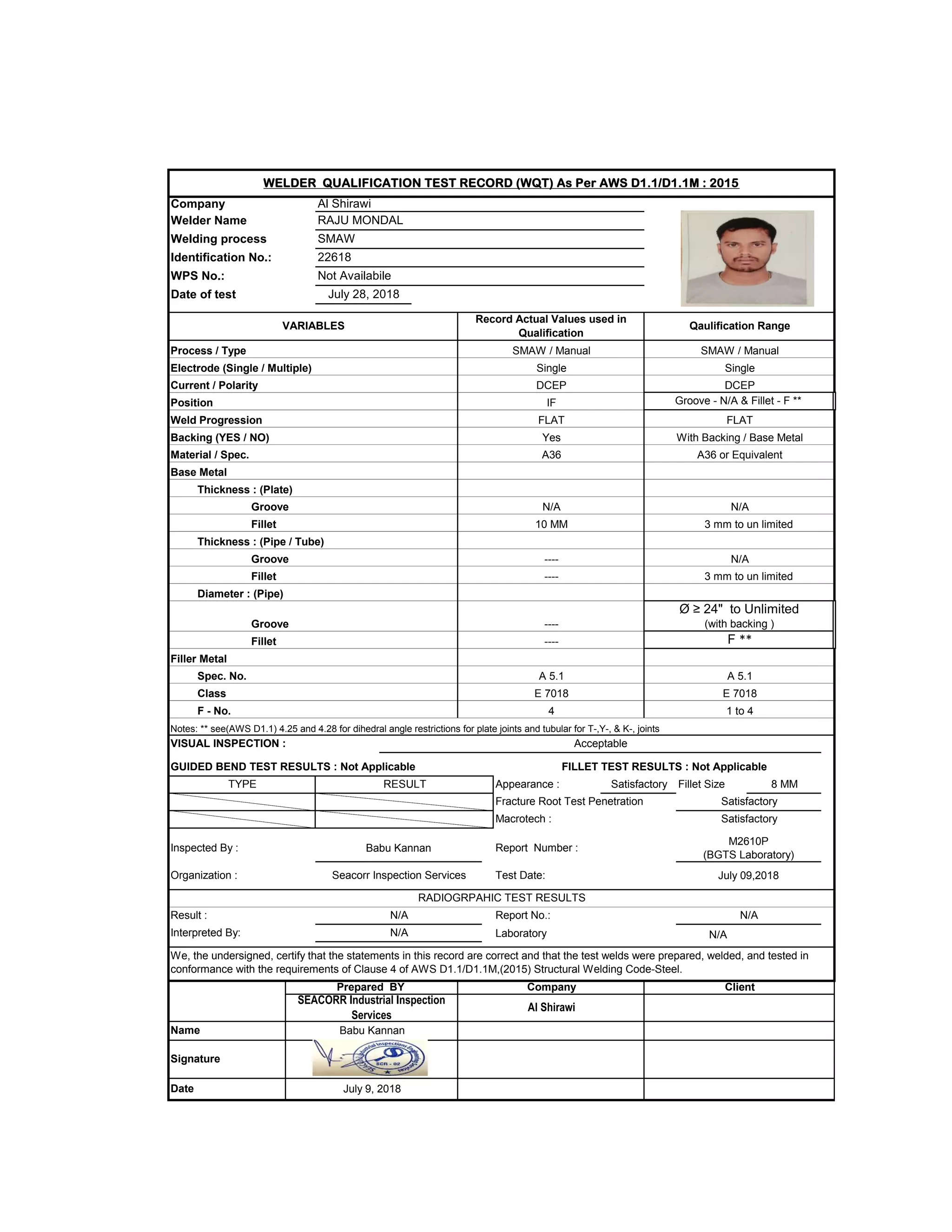

This document summarizes welder qualification test results for welder Raju Mondal using the shielded metal arc welding (SMAW) process. Key details include:

- Test was conducted on July 9, 2018 according to AWS D1.1/D1.1M (2015) requirements

- Visual and macroetch inspections of the test welds found them to be satisfactory

- Welds were made in the flat position with E7018 electrodes on an A36 steel backing using direct current electrode positive polarity

- Test qualified the welder for unlimited fillet welds 3mm or greater in thickness