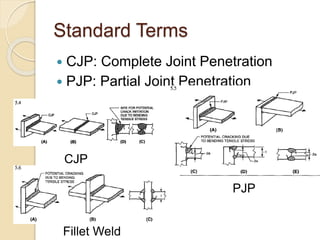

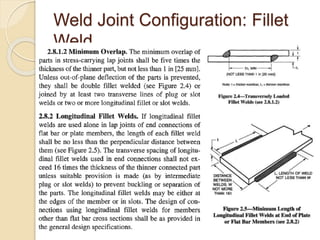

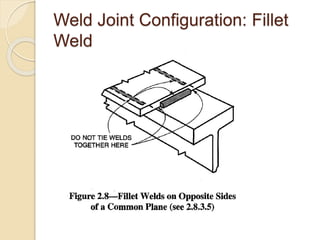

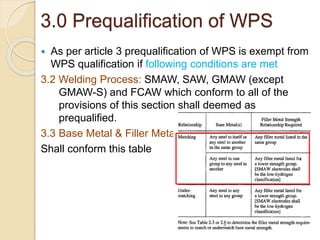

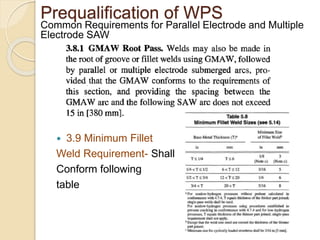

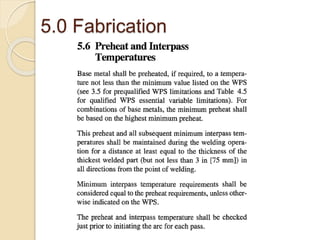

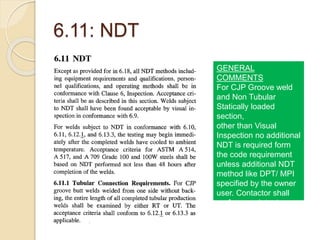

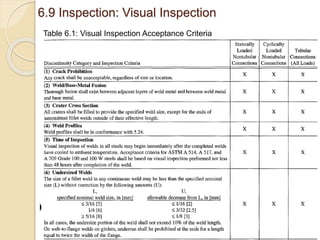

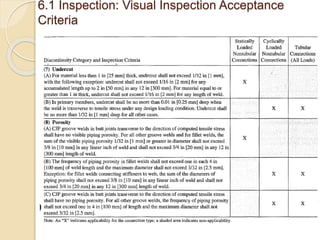

This document provides generalized guidelines for structural steel welding inspection as per the AWS D1.1 Structural Welding Code for Steel. It covers standard terms, the scope of the code, limitations on its use, design of welded connections, weld joint configurations, prequalification of welding procedures, qualification requirements, fabrication, inspection, and non-destructive testing requirements. Key areas addressed include complete and partial joint penetration welds, fillet welds, prequalification criteria for common welding processes and materials, visual inspection acceptance standards, and additional non-destructive testing as required.