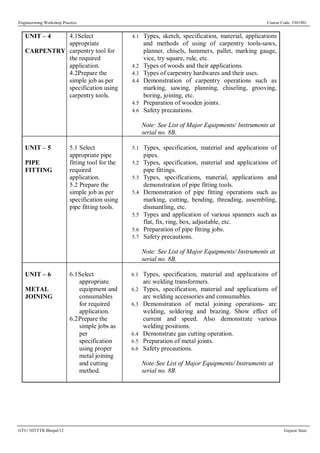

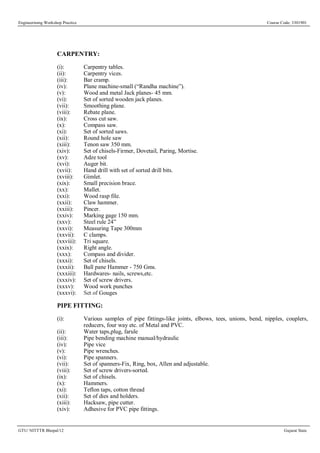

This document outlines the curriculum for an Engineering Workshop Practice course offered at GTU. The course aims to develop relevant technical hand skills for engineering technicians. It covers six units: Introduction to Workshop, Fitting, Tin Smithy, Carpentry, Pipe Fitting, and Metal Joining. Students will learn to use various hand tools in each area and complete simple jobs. The course involves 4 credits of practical work. Assessment includes a practical exam worth 60% and progressive assessments. A list of suggested exercises gives examples of demonstrating tools and completing jobs in each workshop area. Safety is emphasized throughout.