What is mold exhaust?

•

0 likes•9 views

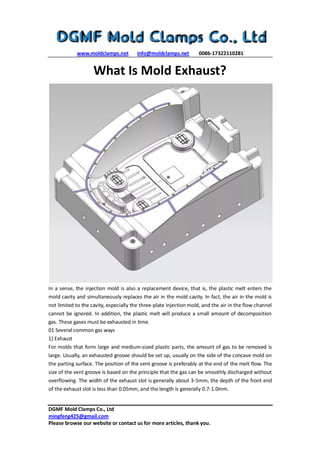

In a sense, the injection mold is also a replacement device, that is, the plastic melt enters the mold cavity and simultaneously replaces the air in the mold cavity. In fact, the air in the mold is not limited to the cavity, especially the three-plate injection mold, and the air in the flow channel cannot be ignored. In addition, the plastic melt will produce a small amount of decomposition gas. These gases must be exhausted in time.

Report

Share

Report

Share

Download to read offline

Recommended

The Indian Dental Academy is the Leader in continuing dental education , training dentists in all aspects of dentistry and offering a wide range of dental certified courses in different formats.

Indian dental academy provides dental crown & Bridge,rotary endodontics,fixed orthodontics,

Dental implants courses.for details pls visit www.indiandentalacademy.com ,or call

0091-9248678078Casting procedures /certified fixed orthodontic courses by Indian dental aca...

Casting procedures /certified fixed orthodontic courses by Indian dental aca...Indian dental academy

More Related Content

What's hot

The Indian Dental Academy is the Leader in continuing dental education , training dentists in all aspects of dentistry and offering a wide range of dental certified courses in different formats.

Indian dental academy provides dental crown & Bridge,rotary endodontics,fixed orthodontics,

Dental implants courses.for details pls visit www.indiandentalacademy.com ,or call

0091-9248678078Casting procedures /certified fixed orthodontic courses by Indian dental aca...

Casting procedures /certified fixed orthodontic courses by Indian dental aca...Indian dental academy

What's hot (20)

To prepare a green sand mould for the solid, split pattern

To prepare a green sand mould for the solid, split pattern

IIIE SECTION A MANUFACTURING TECHNOLOGY NOTES 7.centrifugal casting

IIIE SECTION A MANUFACTURING TECHNOLOGY NOTES 7.centrifugal casting

IIIE SECTION A MANUFACTURING TECHNOLOGY NOTES 6.investment casting

IIIE SECTION A MANUFACTURING TECHNOLOGY NOTES 6.investment casting

Casting procedures /certified fixed orthodontic courses by Indian dental aca...

Casting procedures /certified fixed orthodontic courses by Indian dental aca...

Unit 1 manufacturing technology I Metal casting process

Unit 1 manufacturing technology I Metal casting process

Casting laws/certified fixed orthodontic courses by Indian dental academy

Casting laws/certified fixed orthodontic courses by Indian dental academy

Similar to What is mold exhaust?

International Journal of Excellence Innovation and Development

||Volume 2, Issue 1, Jan. 2019||Page No. 012-015||

Minimization of Sink Mark Defects in Injection Molding Process

Minimization of Sink Mark Defects in Injection Molding ProcessIJEID :: International Journal of Excellence Innovation and Development

Similar to What is mold exhaust? (20)

Casting procedures/cosmetic dentistry course by Indian dental academy

Casting procedures/cosmetic dentistry course by Indian dental academy

How to deal with sink marks on the surface of injection molded products

How to deal with sink marks on the surface of injection molded products

Minimization of Sink Mark Defects in Injection Molding Process

Minimization of Sink Mark Defects in Injection Molding Process

6 points about ejector pins help your injection molding work increase 50%!

6 points about ejector pins help your injection molding work increase 50%!

Manufacturing Technology of Materials in Engineering

Manufacturing Technology of Materials in Engineering

Plastic Ceramic and Glass Processing ppt GTU MANUFACTURING PROCESSES - 2

Plastic Ceramic and Glass Processing ppt GTU MANUFACTURING PROCESSES - 2

Basic requirements for plastic injection molded part design

Basic requirements for plastic injection molded part design

8 tips to troubleshoot injection mold failures -dgmf mold clamps co., ltd

8 tips to troubleshoot injection mold failures -dgmf mold clamps co., ltd

More from JasmineHL

More from JasmineHL (20)

What are the key points of precision injection molding

What are the key points of precision injection molding

Five elements of injection molding process parameters

Five elements of injection molding process parameters

What is the 4 process of plastic injection molding?

What is the 4 process of plastic injection molding?

How to solve flow lines in injection molded products?

How to solve flow lines in injection molded products?

What is the difference between blow molding and injection molding

What is the difference between blow molding and injection molding

Recently uploaded

Recently uploaded (20)

Seizure stage detection of epileptic seizure using convolutional neural networks

Seizure stage detection of epileptic seizure using convolutional neural networks

Software Engineering Practical File Front Pages.pdf

Software Engineering Practical File Front Pages.pdf

NO1 Best Powerful Vashikaran Specialist Baba Vashikaran Specialist For Love V...

NO1 Best Powerful Vashikaran Specialist Baba Vashikaran Specialist For Love V...

Research Methodolgy & Intellectual Property Rights Series 1

Research Methodolgy & Intellectual Property Rights Series 1

Developing a smart system for infant incubators using the internet of things ...

Developing a smart system for infant incubators using the internet of things ...

NEWLETTER FRANCE HELICES/ SDS SURFACE DRIVES - MAY 2024

NEWLETTER FRANCE HELICES/ SDS SURFACE DRIVES - MAY 2024

Theory of Time 2024 (Universal Theory for Everything)

Theory of Time 2024 (Universal Theory for Everything)

Interfacing Analog to Digital Data Converters ee3404.pdf

Interfacing Analog to Digital Data Converters ee3404.pdf

Filters for Electromagnetic Compatibility Applications

Filters for Electromagnetic Compatibility Applications

Working Principle of Echo Sounder and Doppler Effect.pdf

Working Principle of Echo Sounder and Doppler Effect.pdf

Fuzzy logic method-based stress detector with blood pressure and body tempera...

Fuzzy logic method-based stress detector with blood pressure and body tempera...

Seismic Hazard Assessment Software in Python by Prof. Dr. Costas Sachpazis

Seismic Hazard Assessment Software in Python by Prof. Dr. Costas Sachpazis

What is mold exhaust?

- 1. www.moldclamps.net info@moldclamps.net 0086-17322110281 DGMF Mold Clamps Co., Ltd mingfeng425@gmail.com Please browse our website or contact us for more articles, thank you. What Is Mold Exhaust? In a sense, the injection mold is also a replacement device, that is, the plastic melt enters the mold cavity and simultaneously replaces the air in the mold cavity. In fact, the air in the mold is not limited to the cavity, especially the three-plate injection mold, and the air in the flow channel cannot be ignored. In addition, the plastic melt will produce a small amount of decomposition gas. These gases must be exhausted in time. 01 Several common gas ways 1) Exhaust For molds that form large and medium-sized plastic parts, the amount of gas to be removed is large. Usually, an exhausted groove should be set up, usually on the side of the concave mold on the parting surface. The position of the vent groove is preferably at the end of the melt flow. The size of the vent groove is based on the principle that the gas can be smoothly discharged without overflowing. The width of the exhaust slot is generally about 3-5mm, the depth of the front end of the exhaust slot is less than 0.05mm, and the length is generally 0.7-1.0mm.

- 2. www.moldclamps.net info@moldclamps.net 0086-17322110281 DGMF Mold Clamps Co., Ltd mingfeng425@gmail.com Please browse our website or contact us for more articles, thank you. 2) Parting surface exhaust For small molds, the gap between the parting surfaces can be used for exhaust, but the parting surface must be located at the end of the melt flow. 3) Exhaust in the gap of the mosaic For the combined concave mold or cavity, the split gap can be used to exhaust. 4) Exhaust gap clearance Use the gap between the pushrod and the template or core to exhaust, or intentionally add the gap between the pushrod and the template. 5) The exhaust of powder unsintered alloy block Powder unsintered alloy is a material sintered with spherical particle alloy, which has poor strength but the loose texture, allowing gas to pass through. A piece of such an alloy can be placed on the part to be exhausted to meet the exhaust requirements, but the diameter of the bottom vent hole should not be too large to prevent the cavity pressure from squeezing and deforming it. 6) Exhaust well exhaust On the outside of the confluence of plastic melts, a cavity is provided to allow gas to be discharged into it, and a good exhaust effect can also be obtained. 7) Mandatory exhaust In the place where the gas is closed, an exhaust rod is provided. This method has a good exhaust effect but will leave a trace of the rod on the plastic part. Therefore, the exhaust rod should be located in a hidden place of the plastic part. 02 Matters needing attention in exhaust design 1. When the exhaust is extremely difficult, the mosaic structure is adopted. If the dead corner of some molds is not easy to open the exhaust groove, first of all, the mold should be changed to mosaic processing without affecting the appearance and accuracy of the product. Exhaust can also improve the original processing difficulty and facilitate maintenance. 2. At the closed shape of the plastic product, a thimble must be added for exhausting to prevent burns and fusion marks. 3. For product molds with complex geometric shapes, the opening of the exhaust slot is best determined after several trial molds. 4. The more thin-walled products, the farther away from the gate, the opening of the exhaust slot is particularly important. 5. For small parts or precision parts, we must pay attention to the opening of the exhaust slot, because it can avoid the surface burns and insufficient injection volume of the product, and can also eliminate various defects of the product. To sum up Properly opening the exhaust groove can greatly reduce the injection pressure, injection time, holding time and mold clamping pressure, making the plastic parts from difficult to easy, thereby improving production efficiency, reducing production costs, and reducing the energy consumption of the machine.