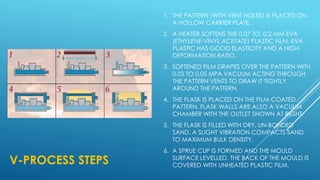

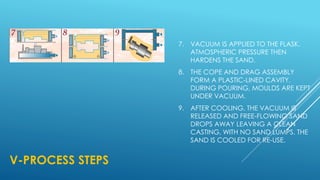

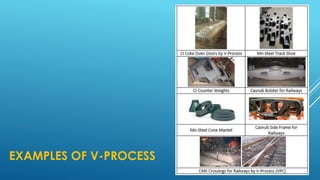

V-process (vacuum process casting) is a binder-free moulding technique that significantly reduces sand costs and pollution, making it particularly suitable for Indian foundries producing railway castings and large wear-resistant steel castings. The process involves several steps using EVA plastic film and vacuum to create high-quality, accurate moulds with minimal sand consumption and no toxic emissions. Benefits include a cost reduction of about 20%, improved surface finish, and increased pattern life.