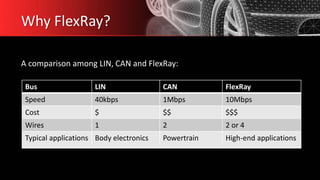

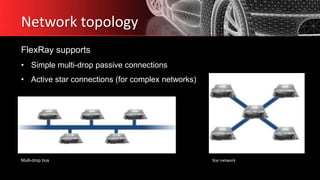

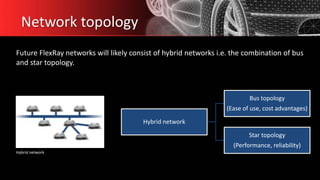

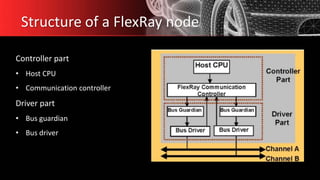

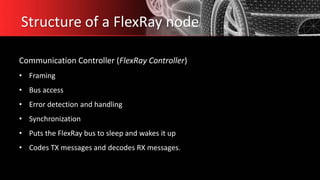

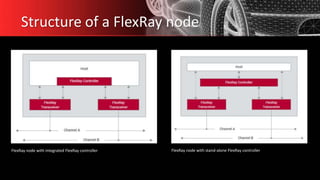

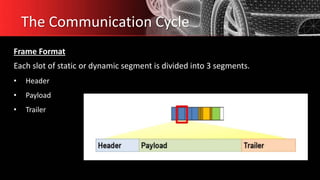

The document provides an overview of the FlexRay protocol, detailing its benefits such as time determinism, fault tolerance, and high speed applications in automotive systems. It discusses the network topology, the structure of a FlexRay node, the communication cycle, and its frame format. FlexRay is positioned as a robust communication technology crucial for modern automotive control systems, emphasizing its flexibility and performance advantages over older protocols.