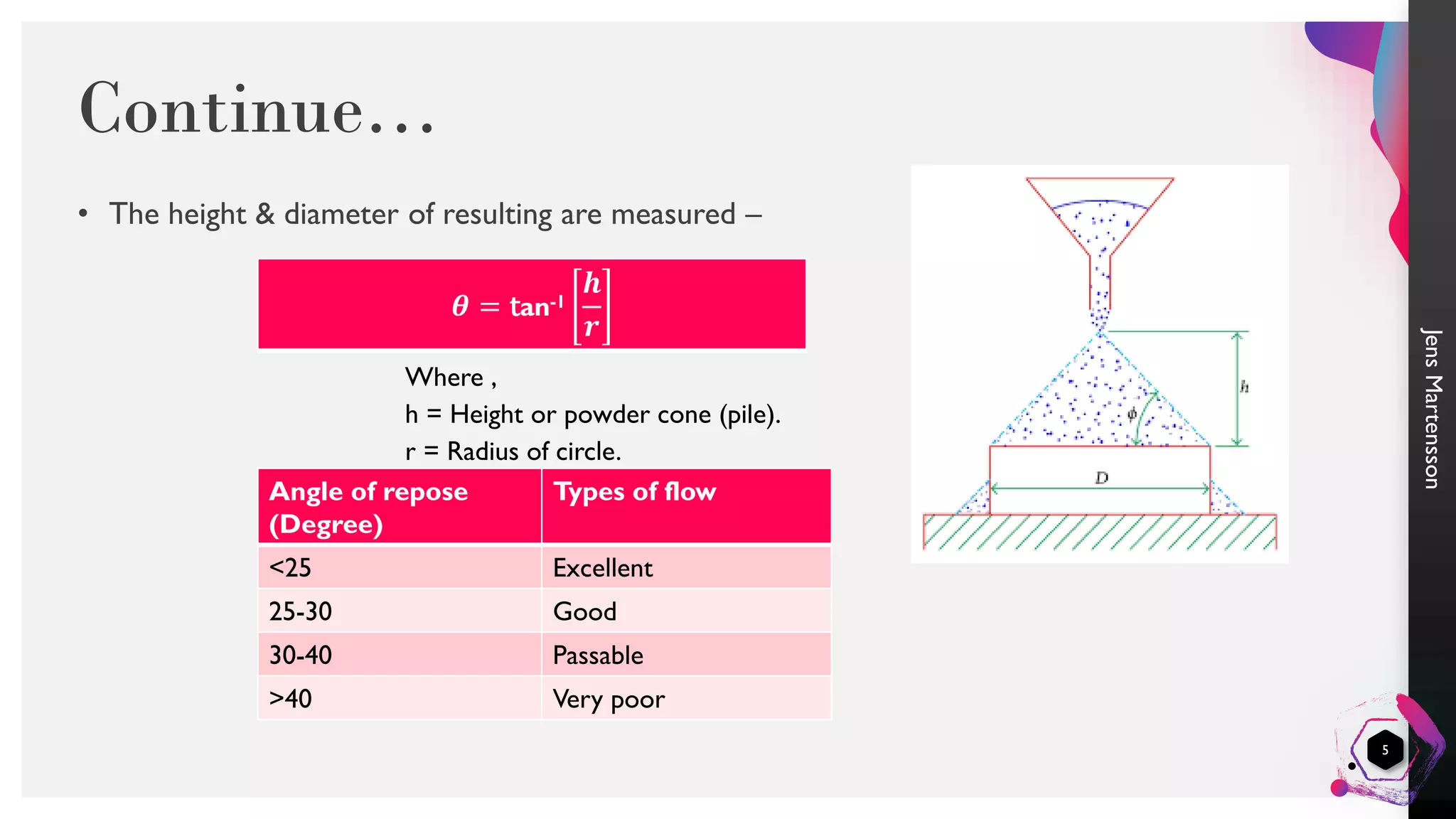

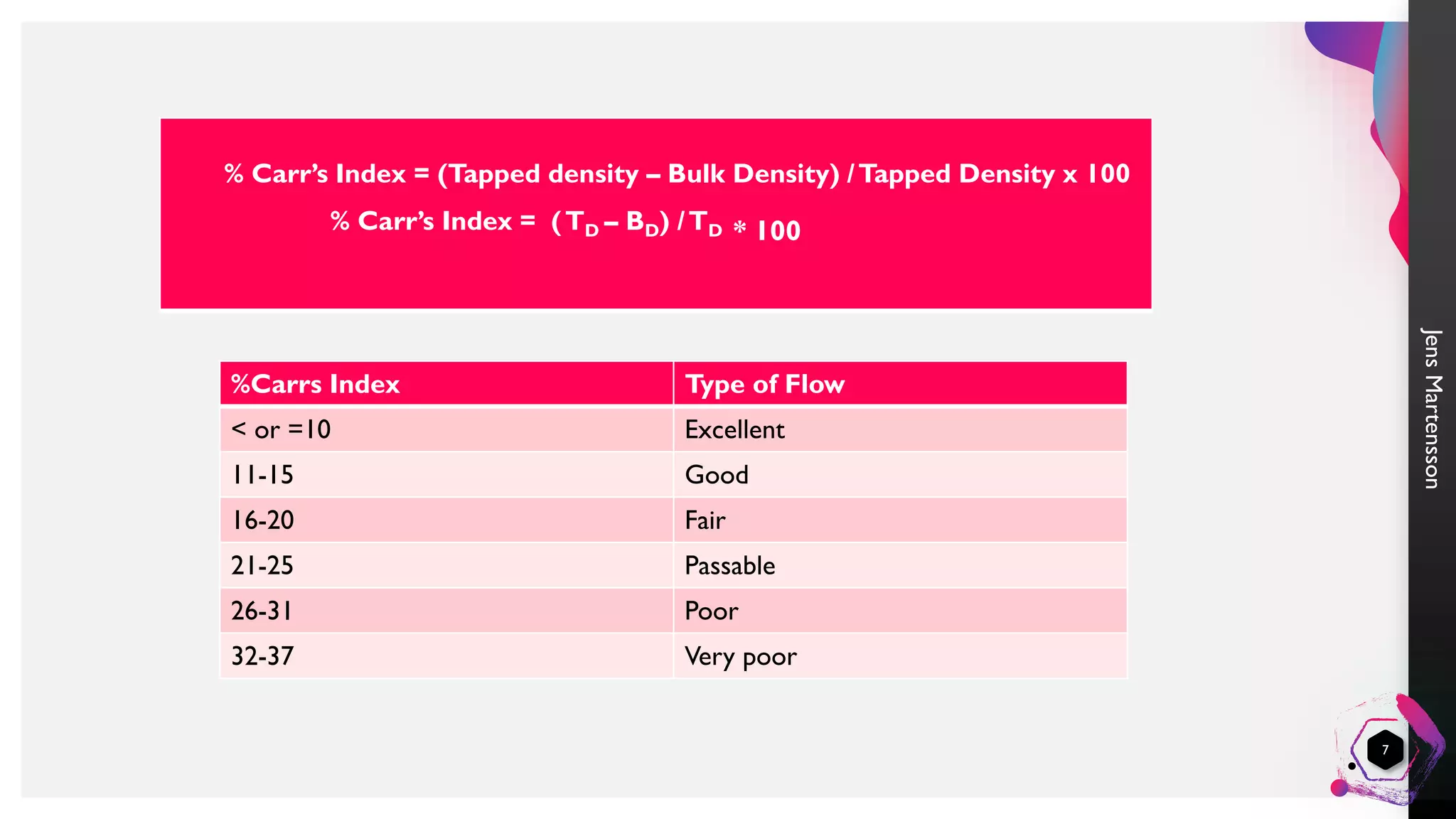

Powder flow properties are affected by particle size, shape, density, and forces like friction and cohesion between particles. Tests like angle of repose, Carr's compressibility index, and Hausner's ratio are used to evaluate a powder's flowability, with lower angles and ratios generally indicating better flow. The angle of repose is determined by allowing powder to flow through a funnel onto a surface, with flow classified as excellent below 25 degrees and very poor above 40 degrees. Carr's index and Hausner's ratio both compare a powder's bulk and tapped densities to characterize flow, with better flow indicated by lower percentage values.