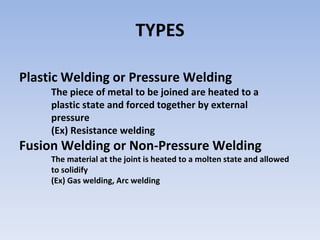

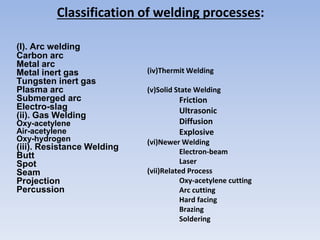

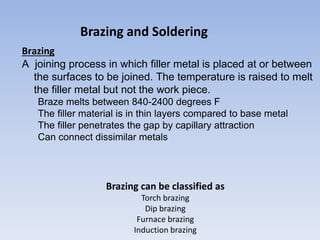

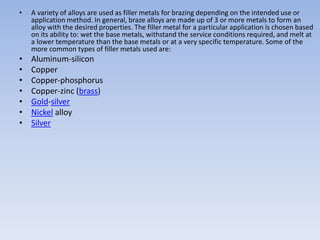

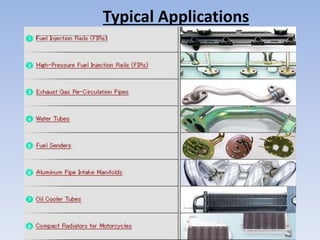

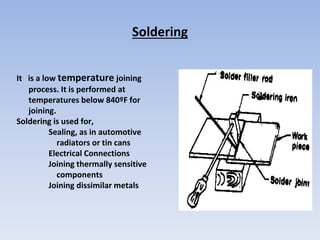

This document discusses different welding and joining processes. It begins by defining welding as a process that joins materials through heating and sometimes the use of filler material. It then discusses different types of welding processes, including plastic/pressure welding and fusion/non-pressure welding. The document further classifies welding into several categories such as arc, gas, resistance, thermit, solid state, and newer welding processes. It also discusses related processes like cutting and brazing. Finally, it provides details on brazing and soldering, defining them as lower temperature joining processes compared to welding and discussing their applications and advantages/disadvantages.