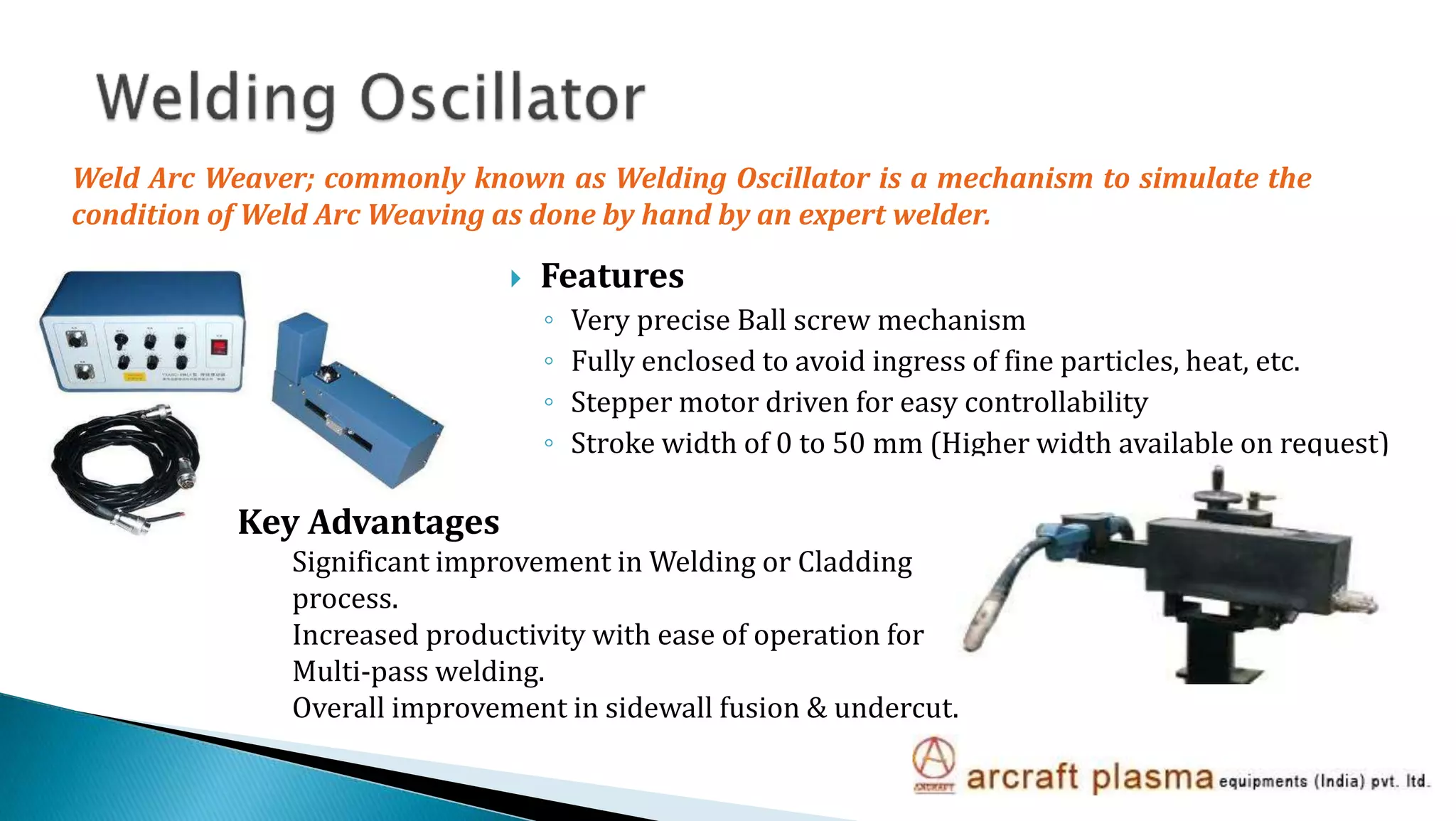

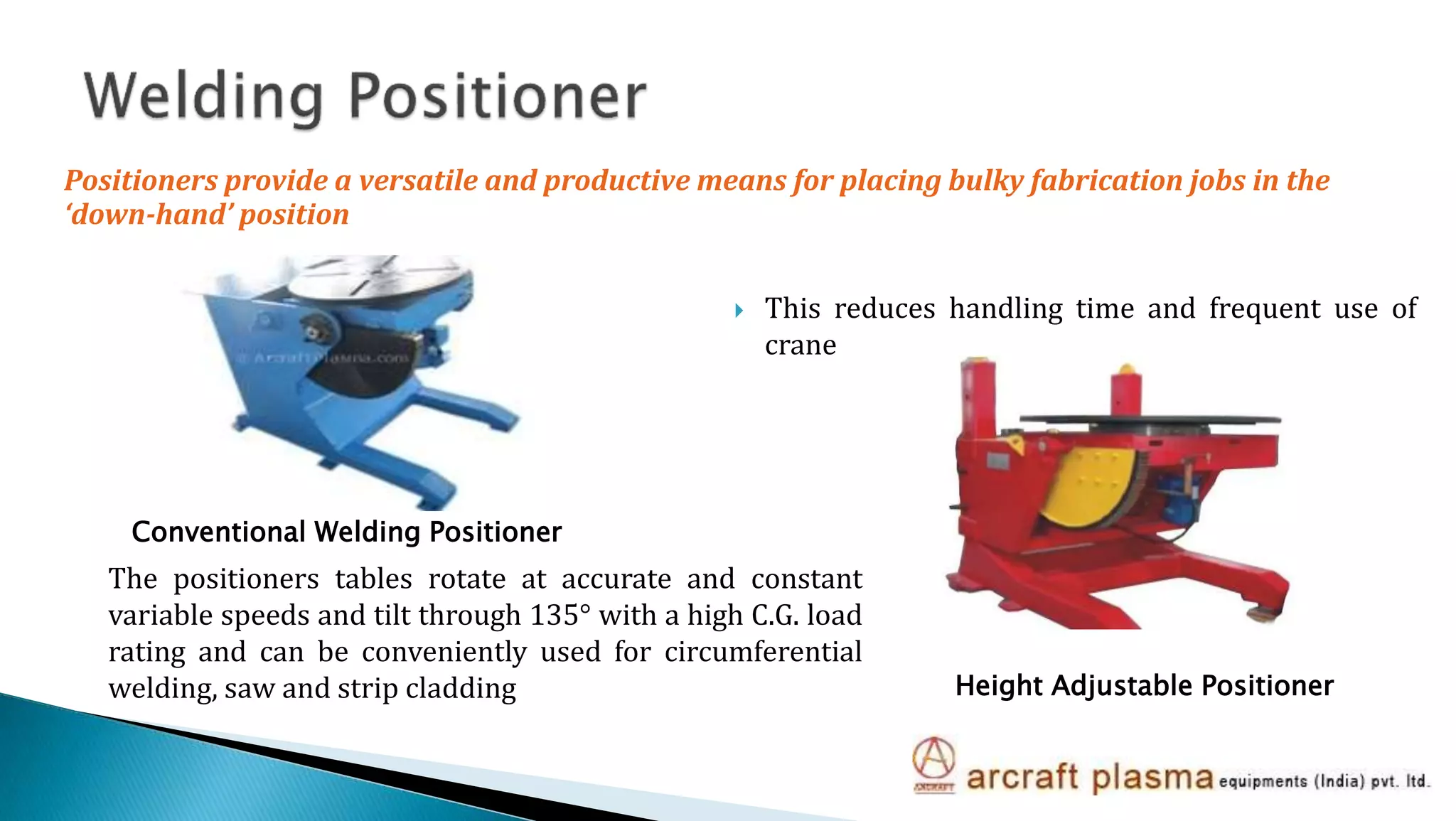

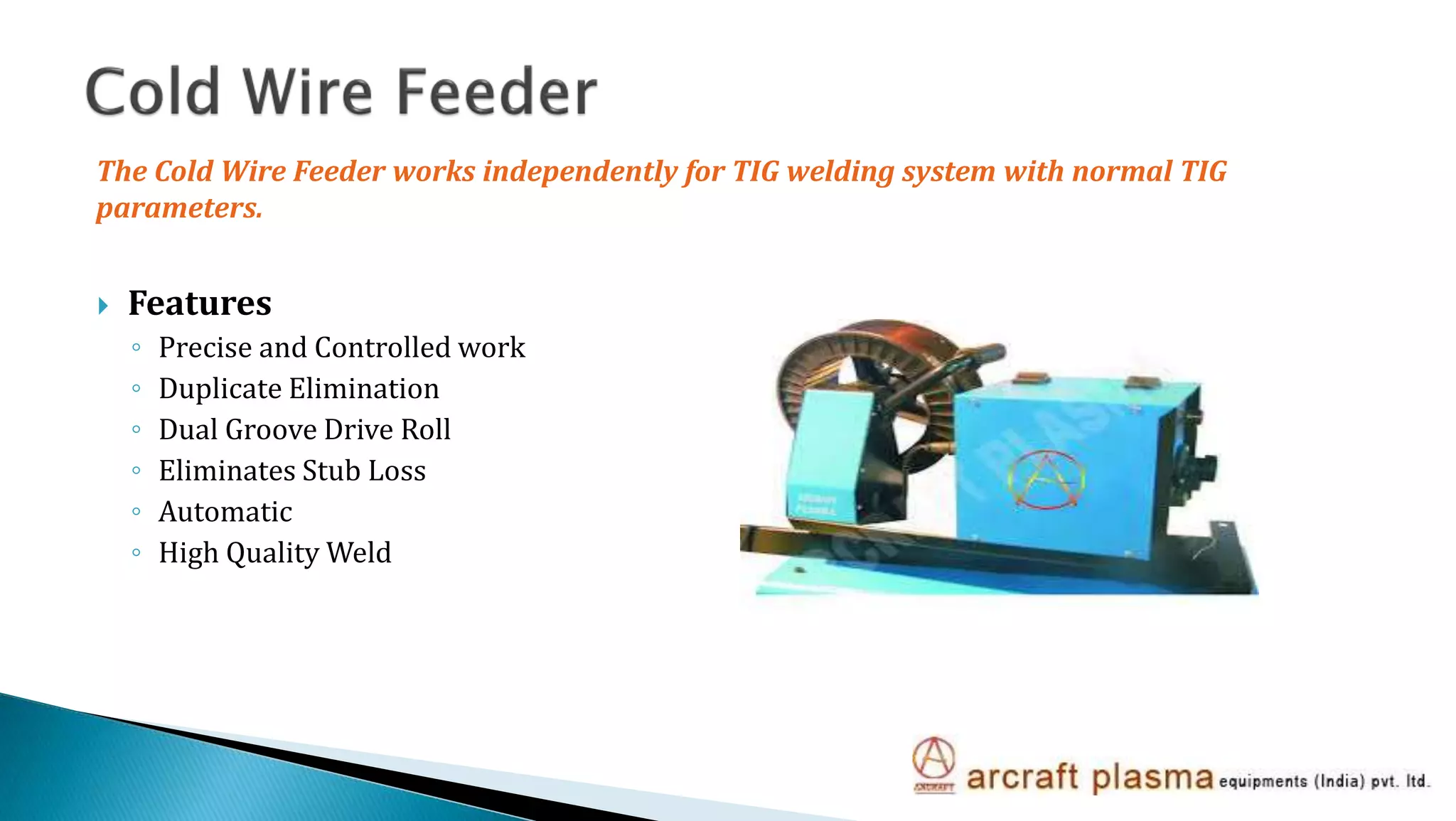

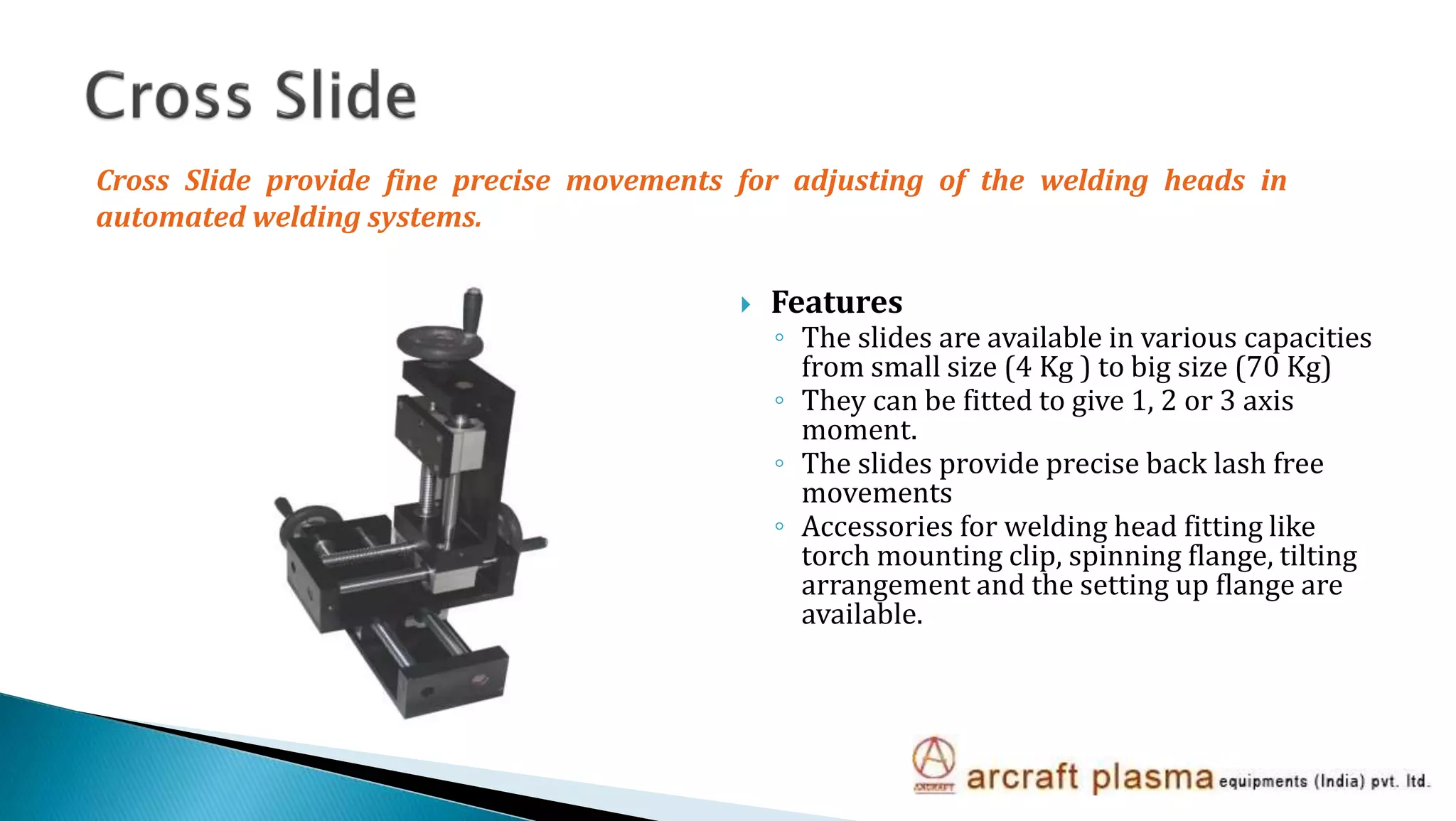

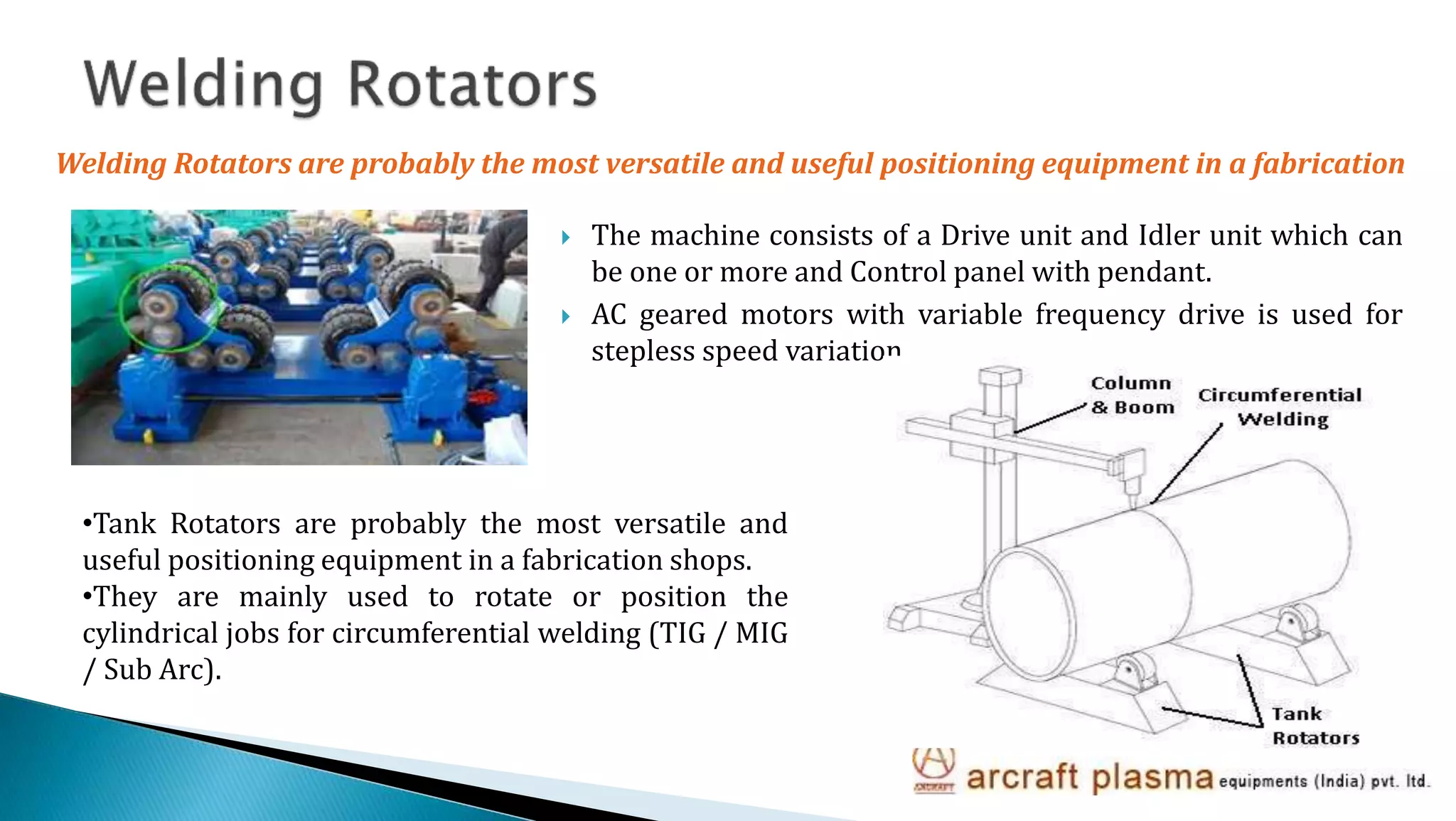

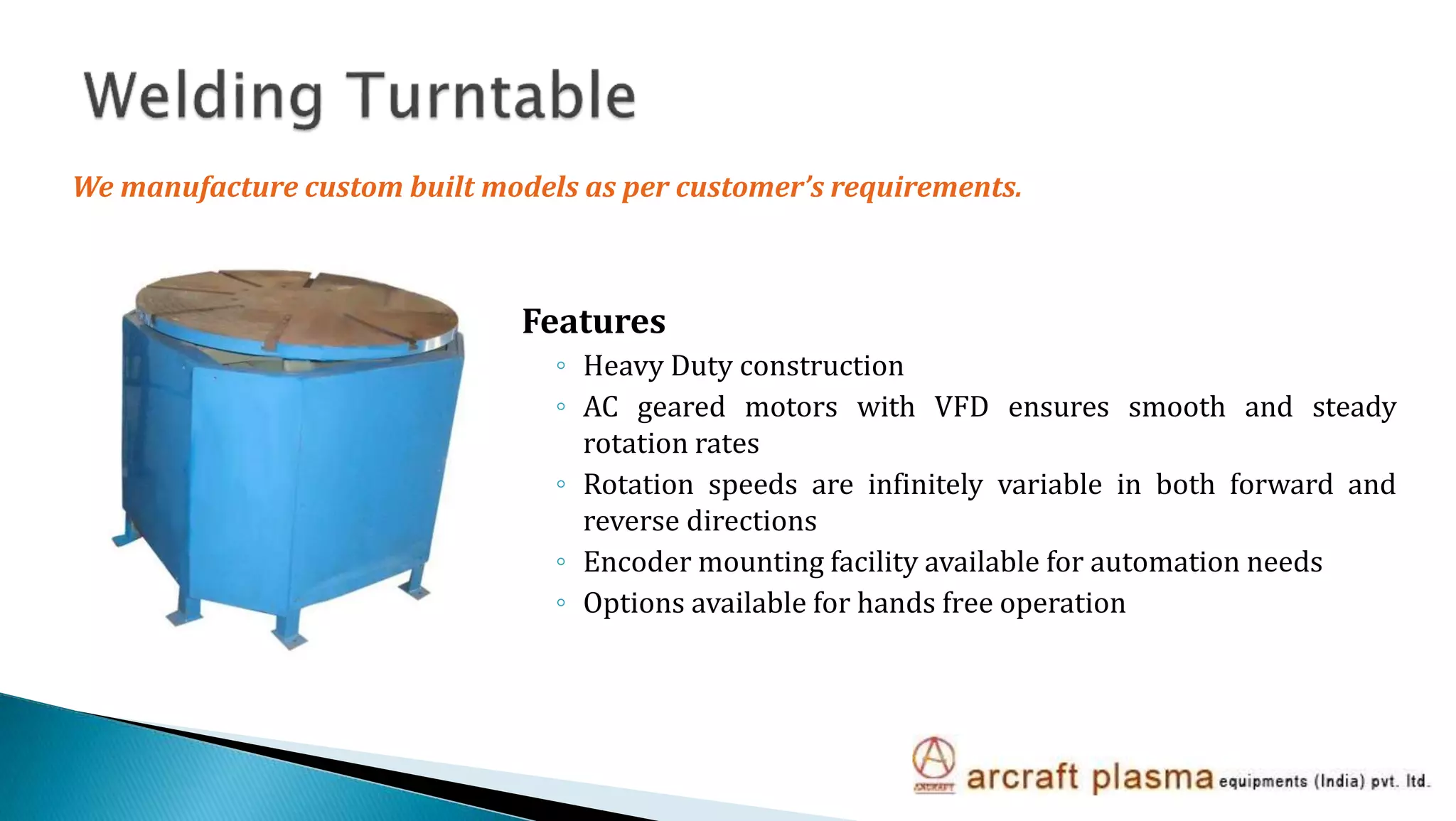

Arcraft provides automated welding systems to improve welding quality and productivity while reducing costs. Their equipment includes welding oscillators, positioners, guns, columns, booms, cross slides, lathes, turntables, wire feeders, seam trackers, and tank rotators. These systems automate welding to enhance the working environment. Features include precision mechanisms, enclosure, controllability, stroke control, and duplication elimination. The document provides details on various automation equipment and their advantages in improving welding processes.