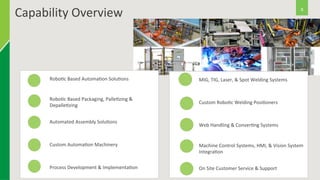

Midwest Engineering Systems Inc. provides automation and robotics solutions for manufacturers. It has over 110 employees across multiple locations and offers services including custom automation equipment, robot integration, assembly line automation, and retrofitting of existing systems. The document provides an overview of Midwest Engineering's capabilities, industries it serves, and technical areas of expertise.