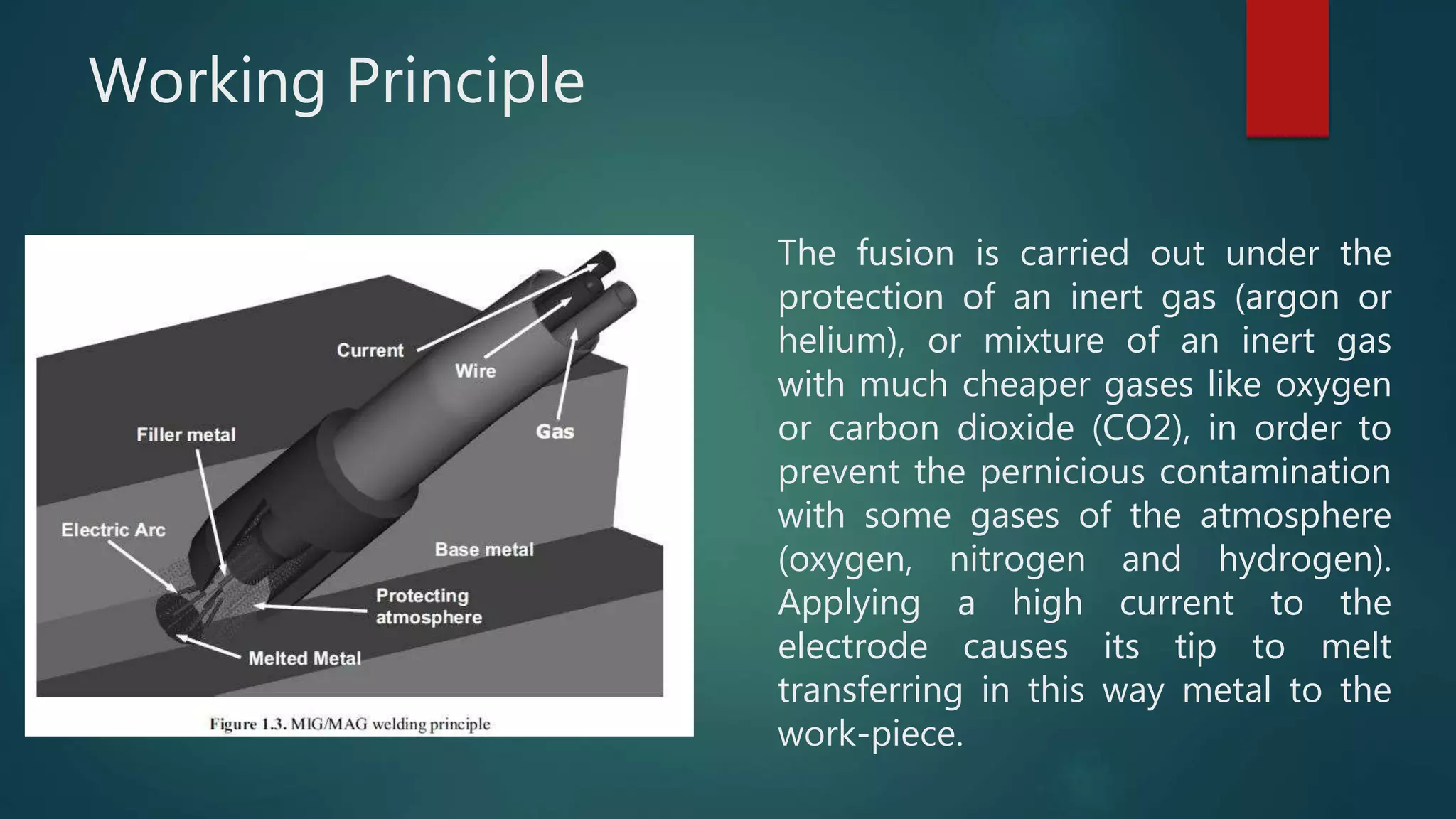

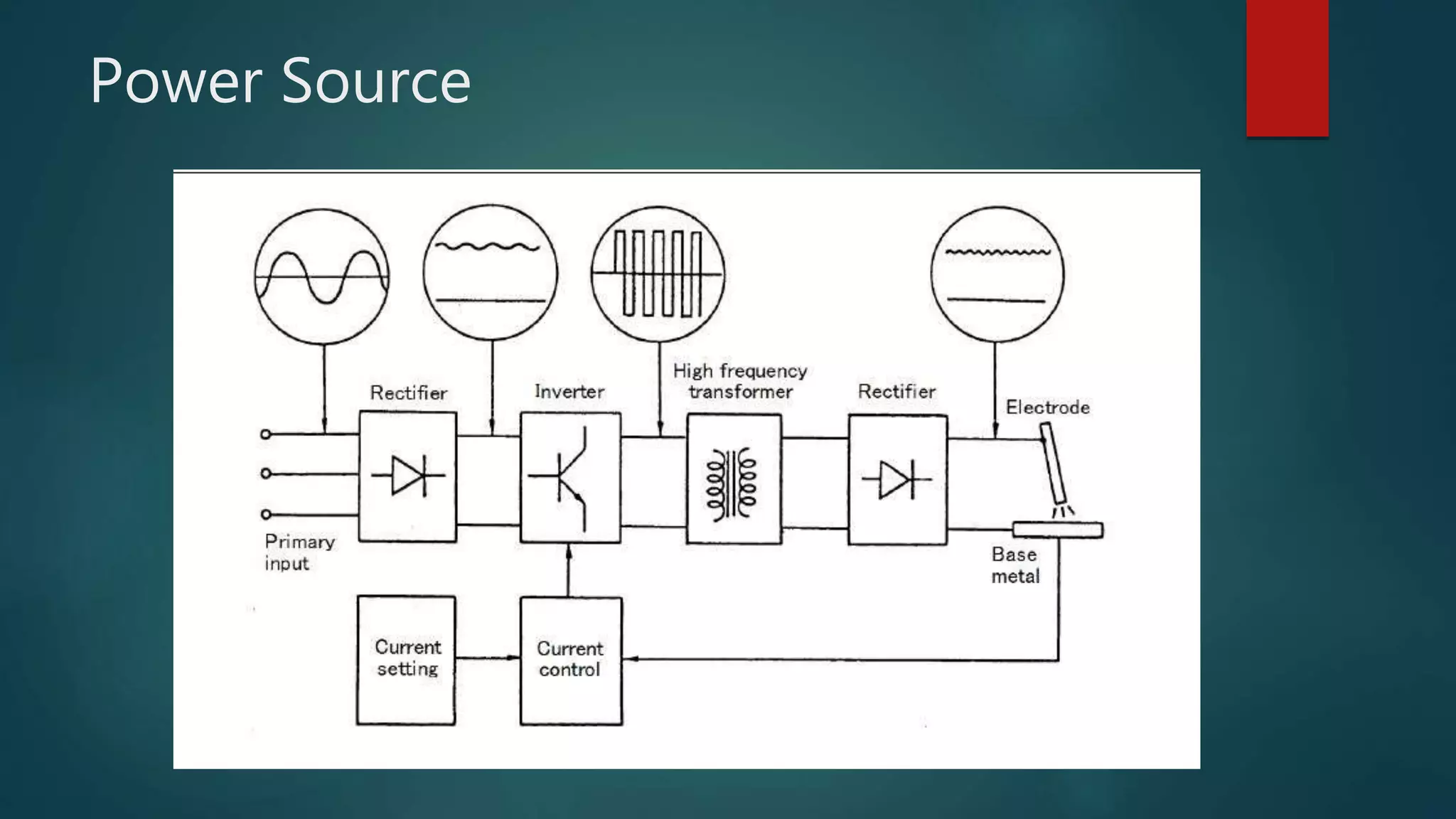

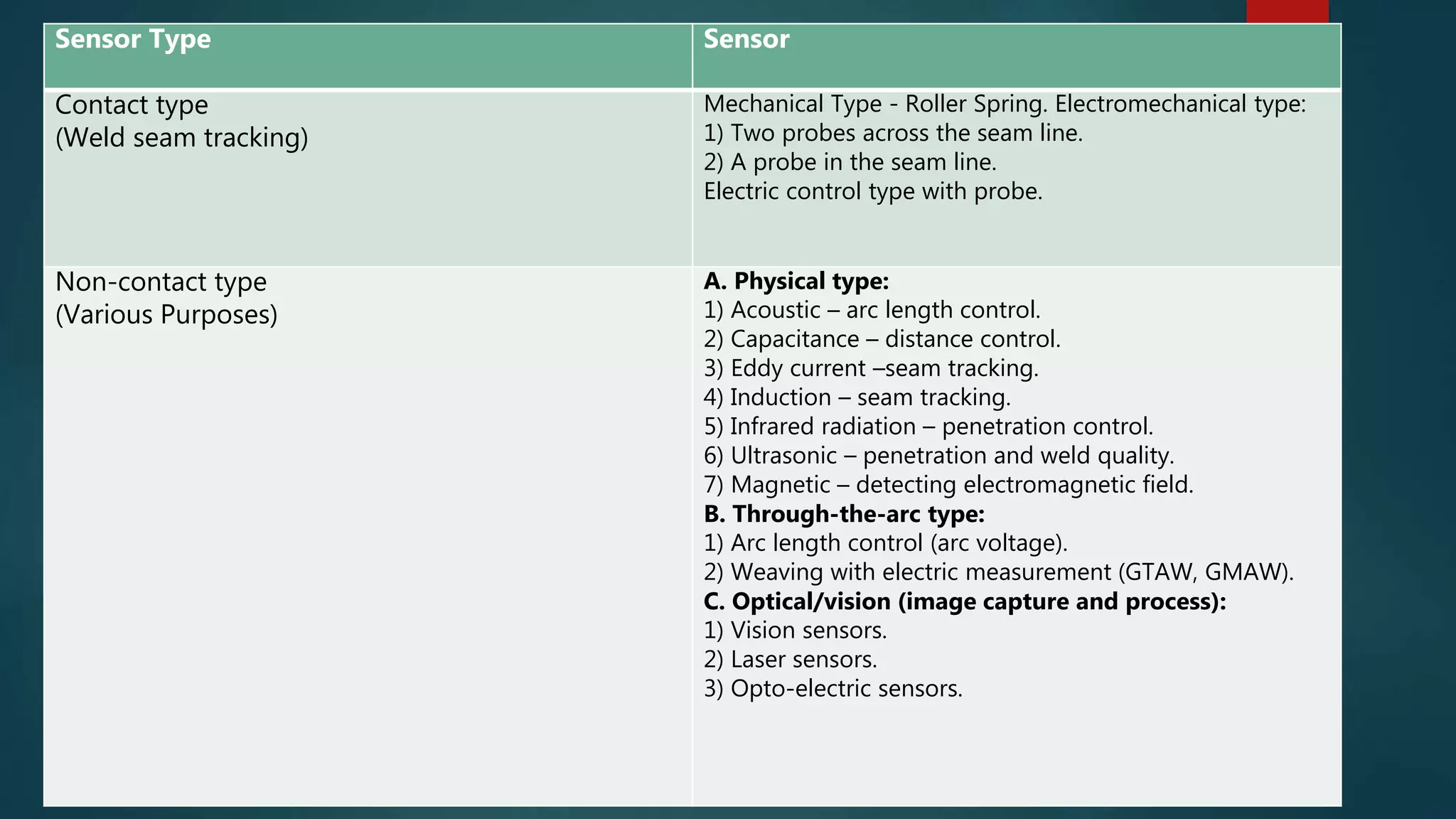

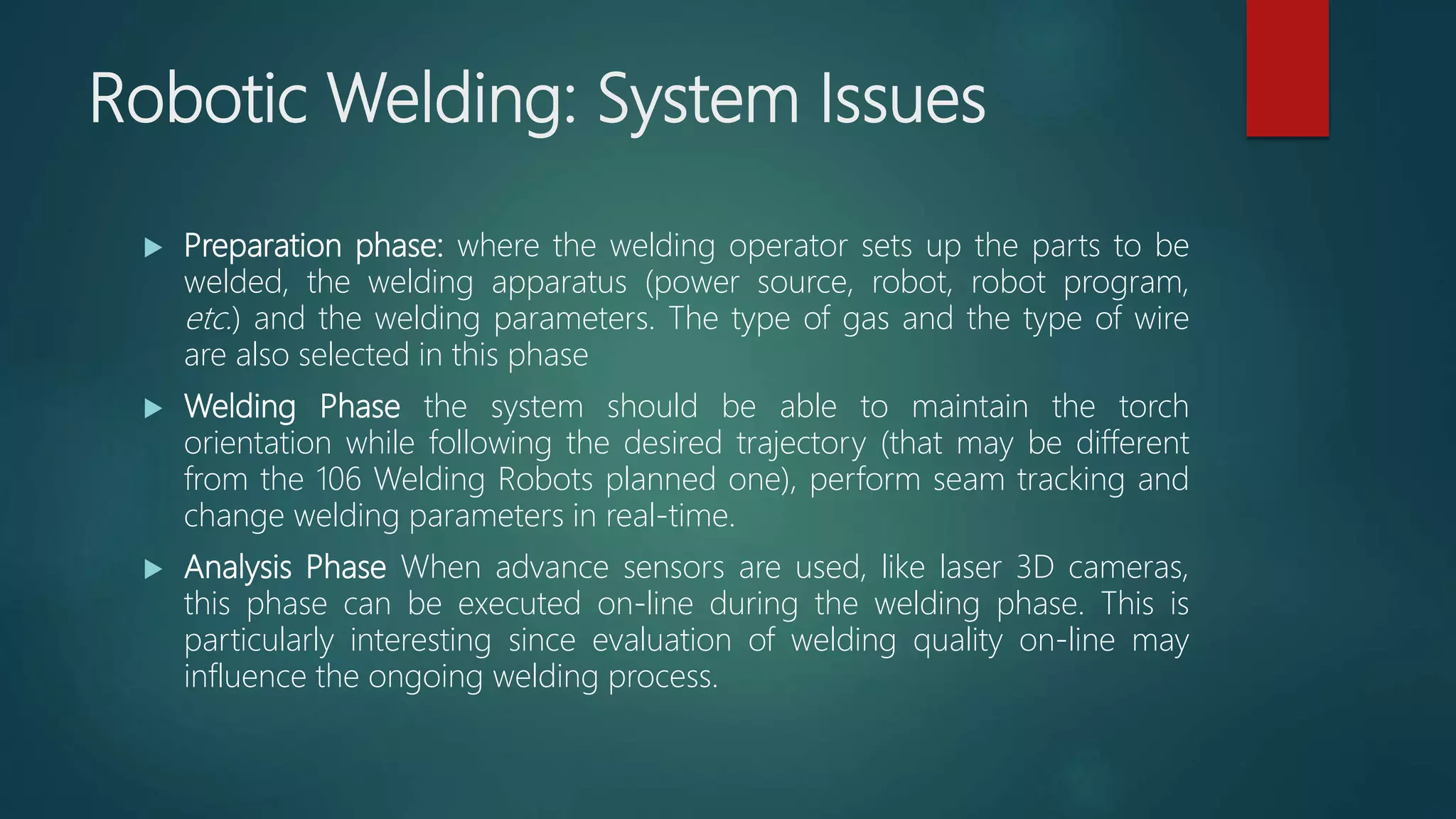

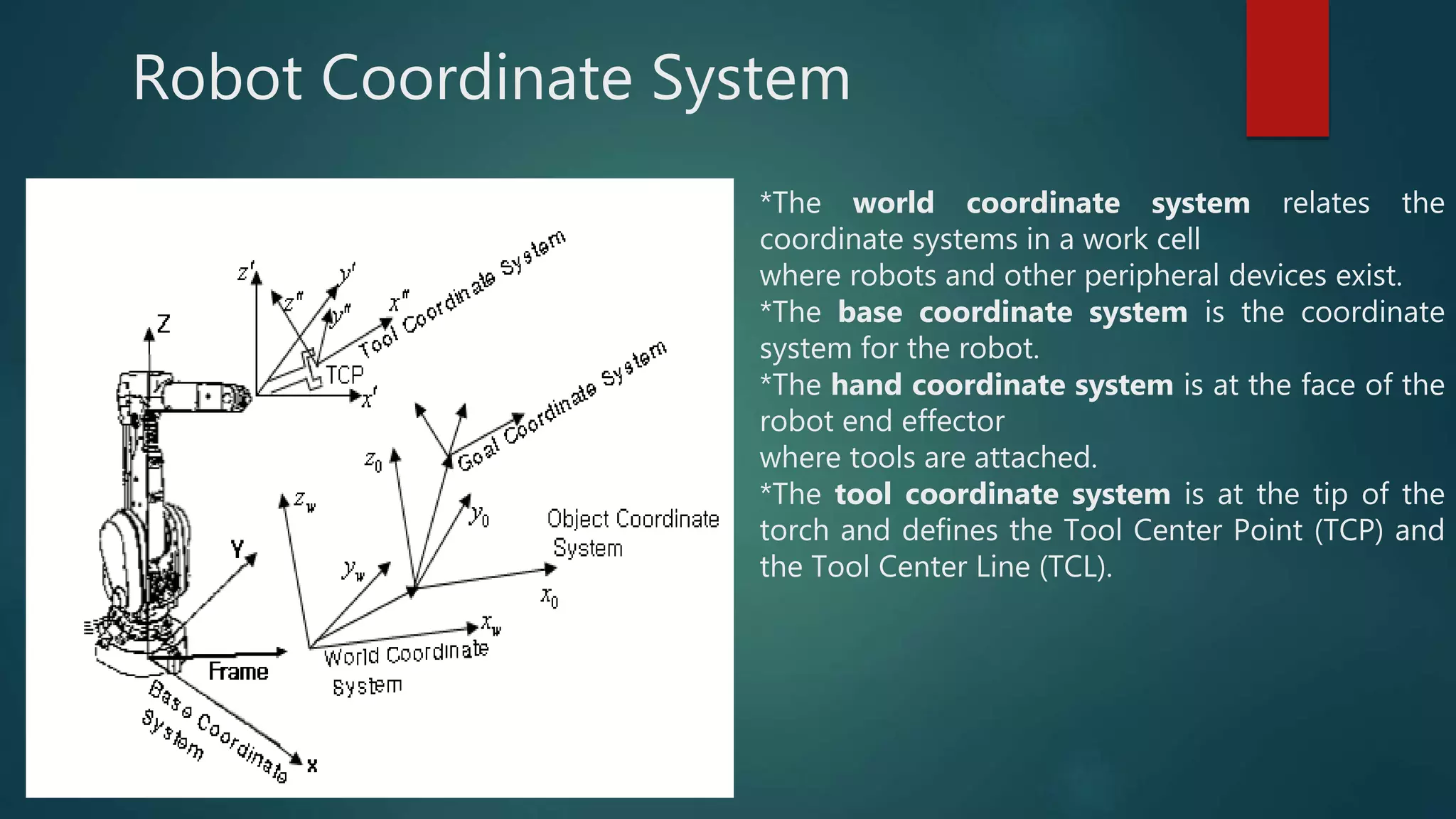

The document discusses robotic welding technology, detailing its principles, processes, and the advantages of automation in welding applications. It covers various welding techniques, the role of sensors, and the requirements for effective robotic systems, including setup, execution, and monitoring phases. Additionally, it highlights the importance of adaptability and precision in manufacturing environments that utilize welding robots.