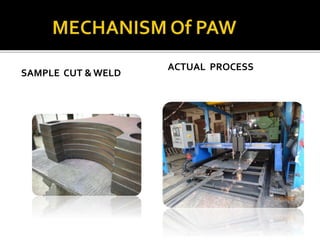

The document presents information on plasma arc welding. It discusses two types of plasma arc welding: transferred arc and non-transferred arc. Plasma arc welding uses an arc between a tungsten electrode and workpiece to weld metals like steel, iron, aluminum and alloys. The plasma jet reaches temperatures over 50,000 degrees Fahrenheit, much hotter than a standard electric arc, allowing it to melt and blow away molten metal during cutting. The document also provides details on plasma cutting and welding systems, including their portability, controls, consumables, cutting capacities and applications on various metals.