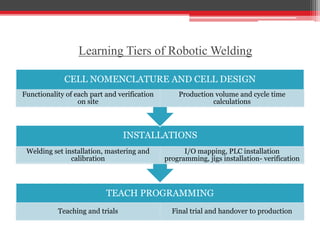

Prateek Sood completed an industrial training at VEEGEE KAUSHICKO ENGINEERING PVT. LTD. The training focused on learning about robotic welding through teaching programming, installations, cell design, and hands-on work. During the training, Prateek learned robotic functionality, welding machine basics, robot teaching, PLC programming, and production calculations. The training helped develop practical skills and confidence needed to work in the robotics and manufacturing field.