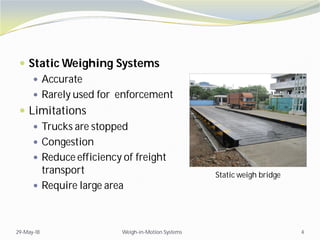

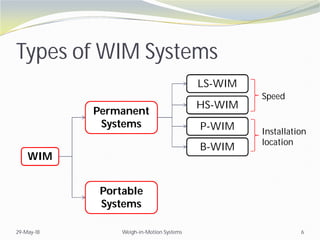

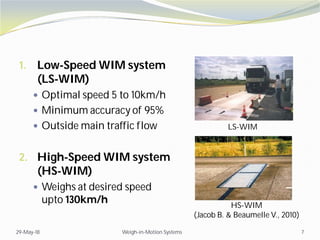

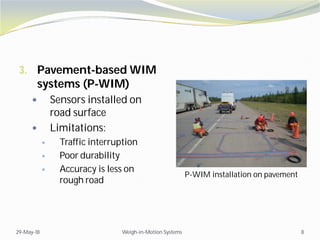

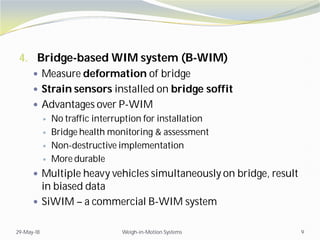

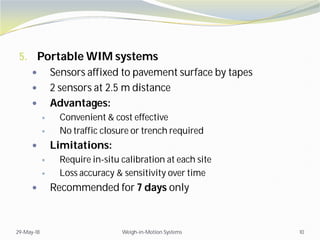

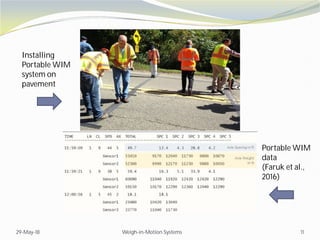

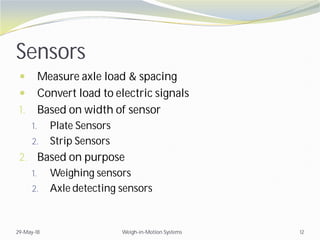

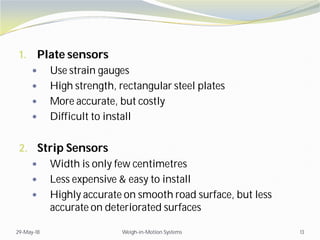

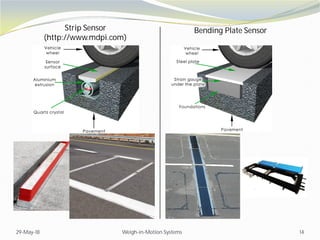

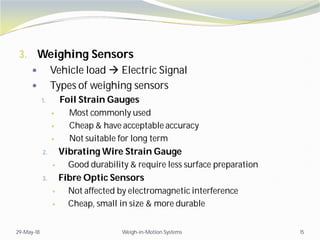

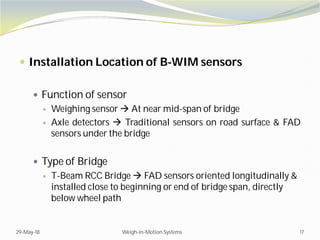

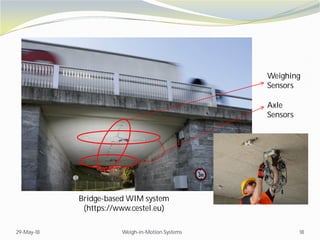

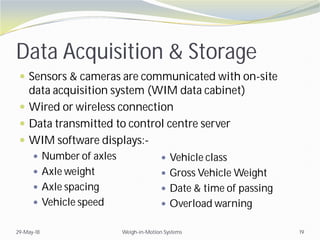

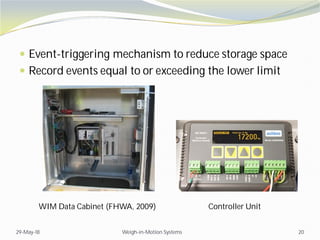

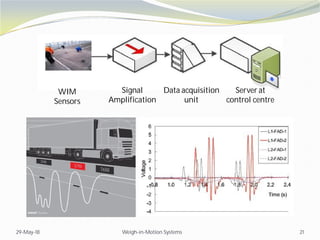

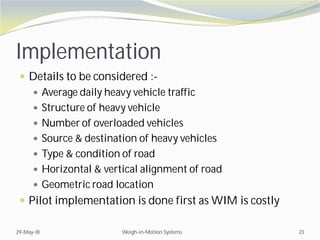

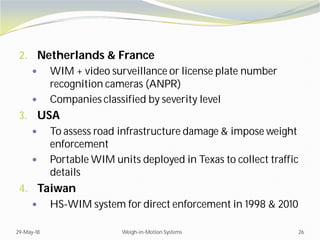

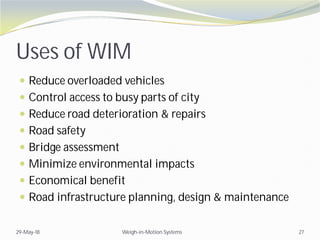

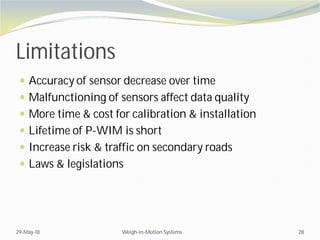

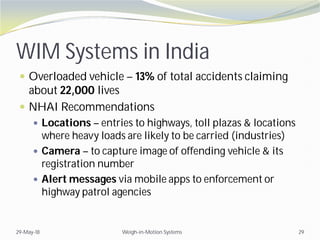

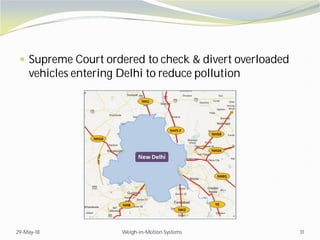

The document discusses weigh-in-motion (WIM) technology, its types, sensors, and data acquisition methods, highlighting its significance in managing vehicle overloading and improving road safety. It details various WIM systems such as low-speed and high-speed installations, along with their advantages and limitations. The effectiveness and implementation of WIM systems in traffic management, including case studies from various countries, are also examined, emphasizing their role in reducing road deterioration and enhancing traffic data collection.