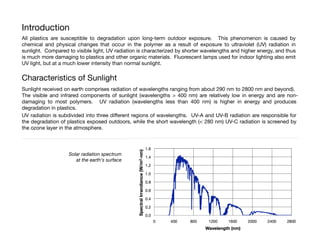

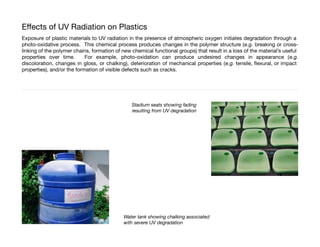

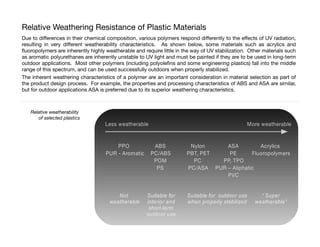

The document discusses the susceptibility of plastics to degradation due to UV radiation from sunlight, detailing the photo-oxidative processes that lead to structural changes in polymers. It highlights the differing weathering resistance of various plastics based on their chemical composition, emphasizing the importance of selecting materials with suitable weatherability for outdoor applications. Accelerated weathering testing methods, particularly for the automotive industry, are addressed, with warnings about the limitations of using such tests to predict outdoor performance.