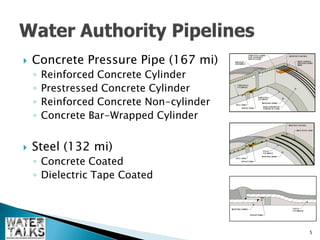

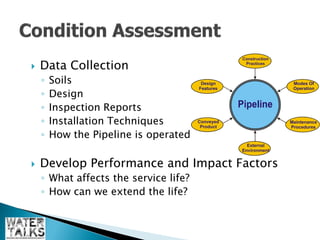

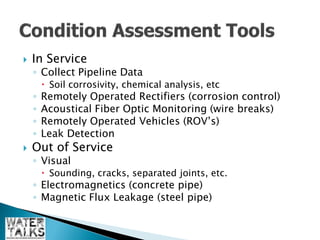

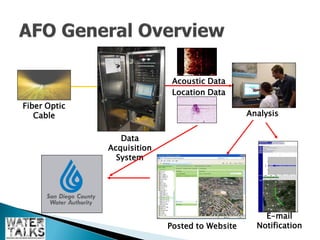

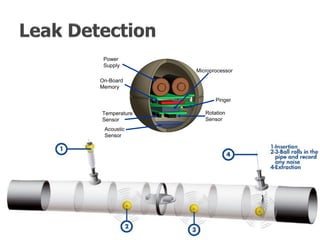

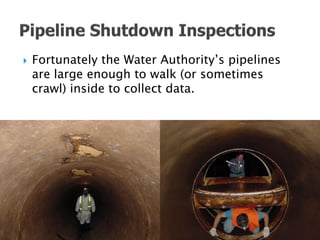

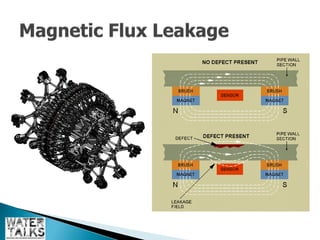

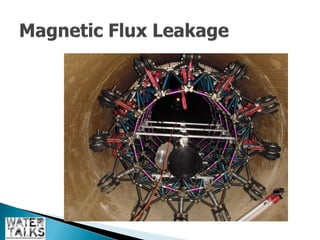

The document outlines the operations and maintenance practices for water pipelines, detailing the types of pipes used and construction methods. It emphasizes the importance of data collection for assessing pipeline performance and health, including techniques for both in-service and out-of-service evaluation. Additionally, it discusses the benefits of utilizing remotely operated vehicles (ROVs) for inspections, highlighting their role in reducing costs and environmental impacts.