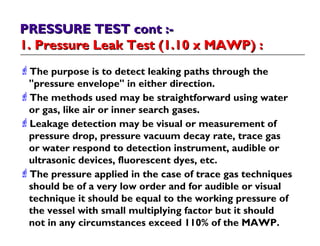

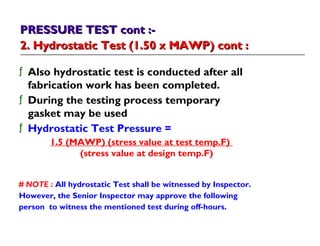

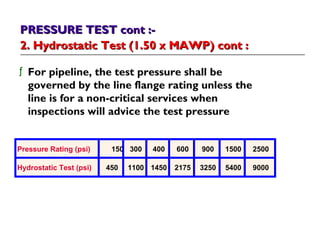

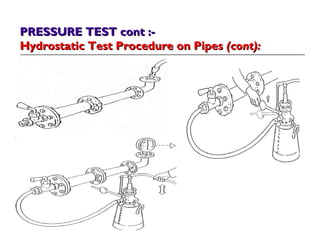

The document outlines the procedure and regulations for pressure testing of pressure vessels in Malaysia, highlighting two main types of tests: pressure leak tests and hydrostatic tests. It emphasizes the importance of these tests to ensure safety, prevent accidents, and protect the environment. Additionally, it provides detailed definitions, test procedures, and safety requirements to be followed during the testing process.