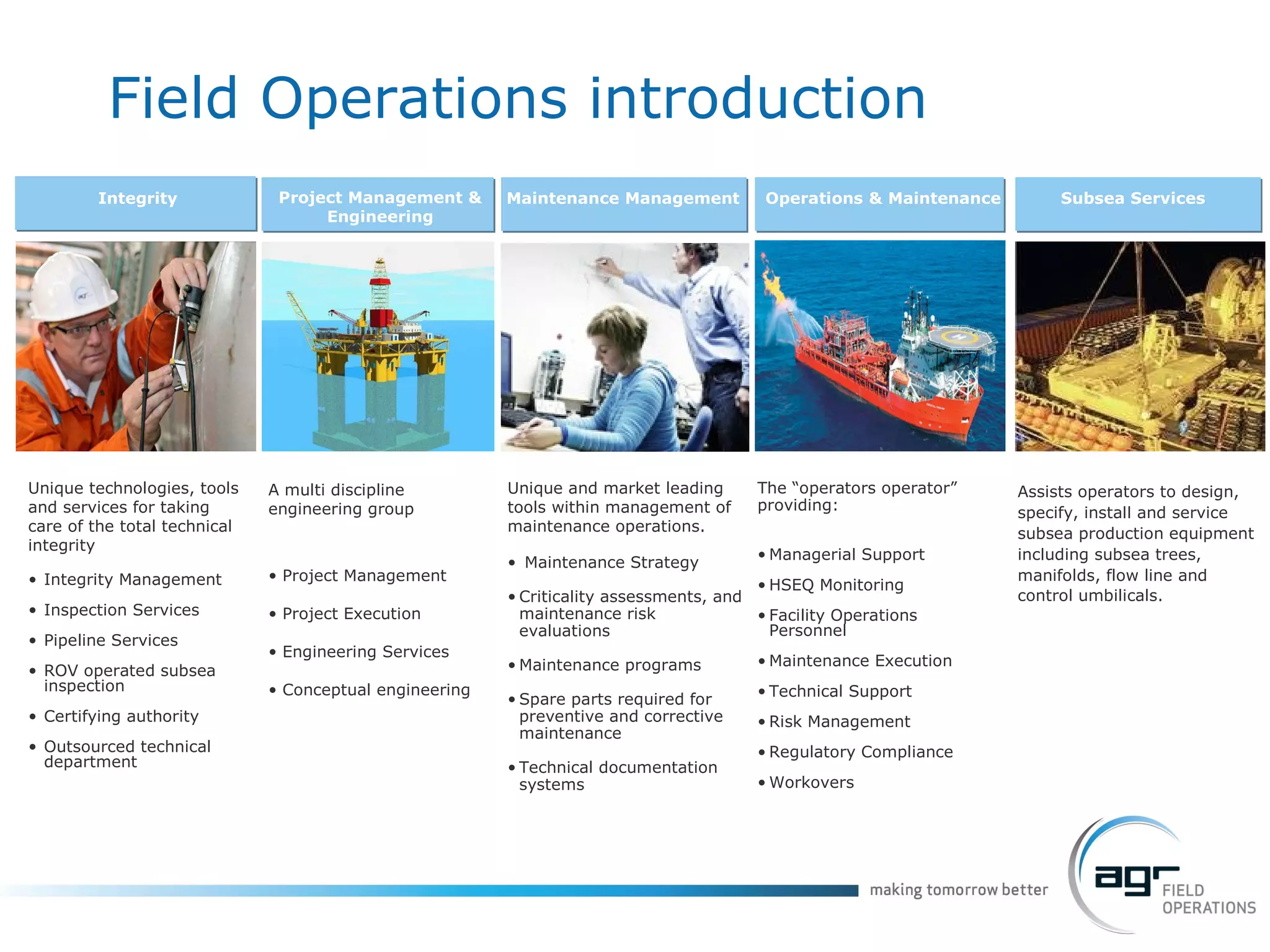

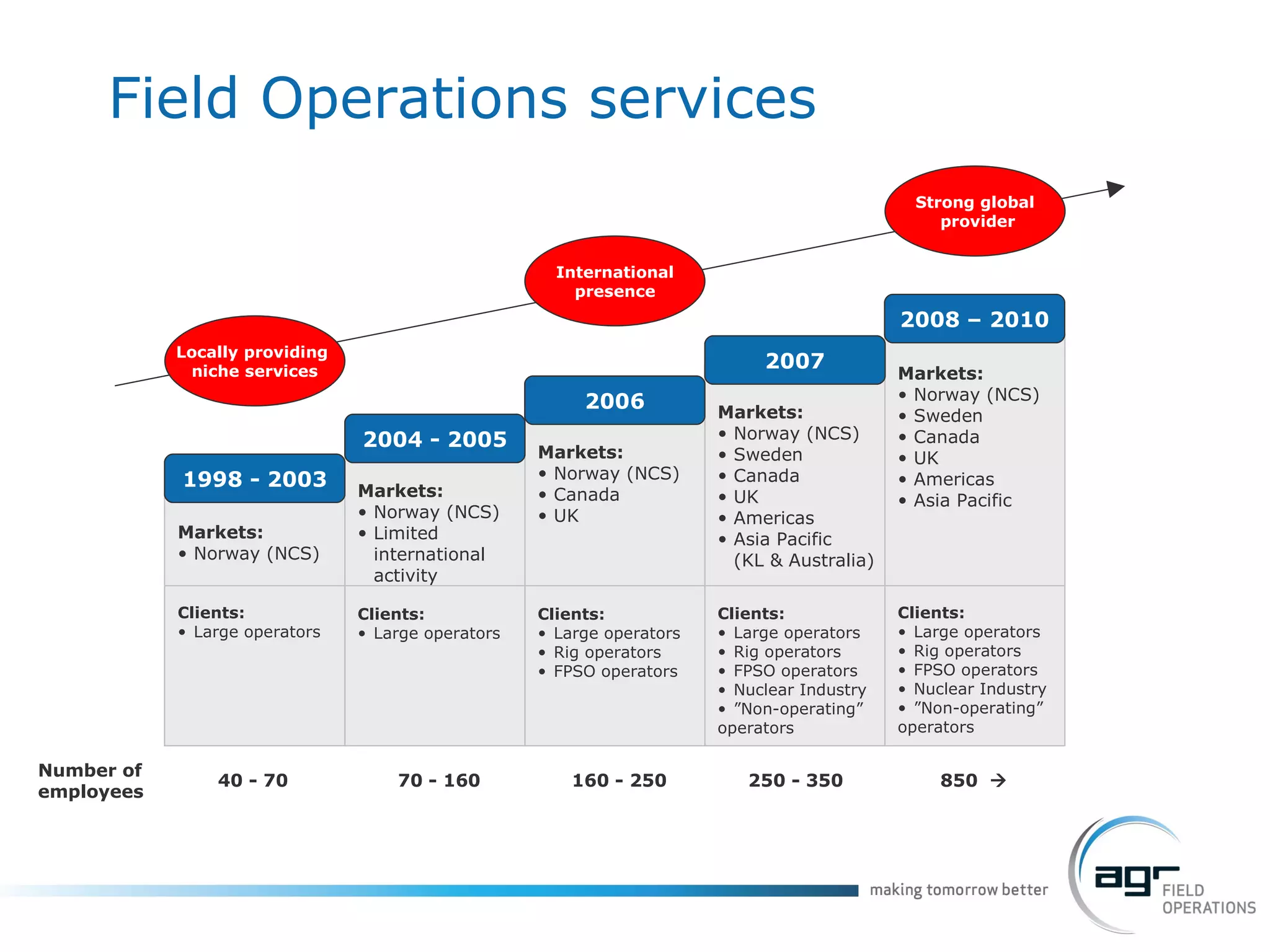

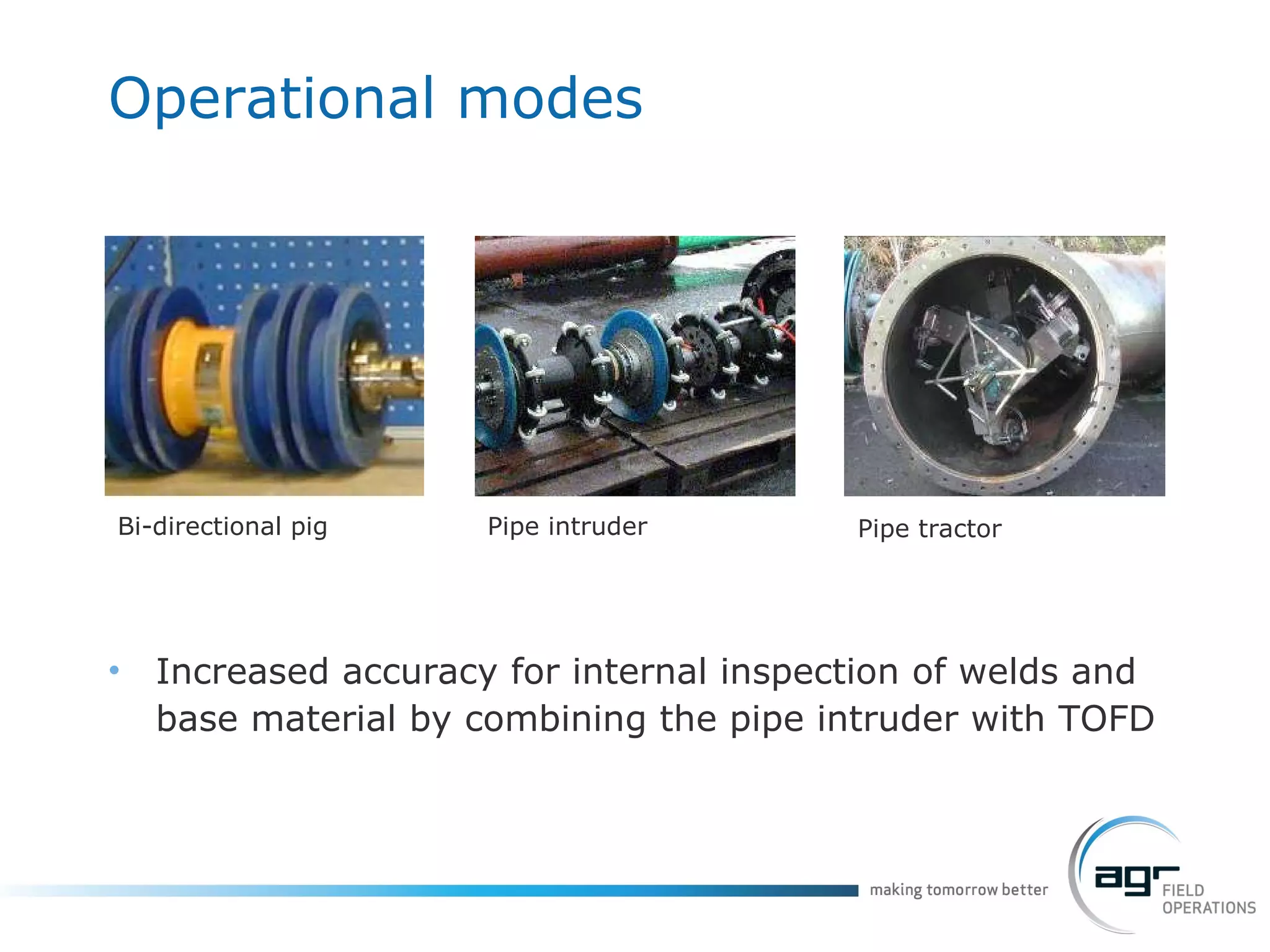

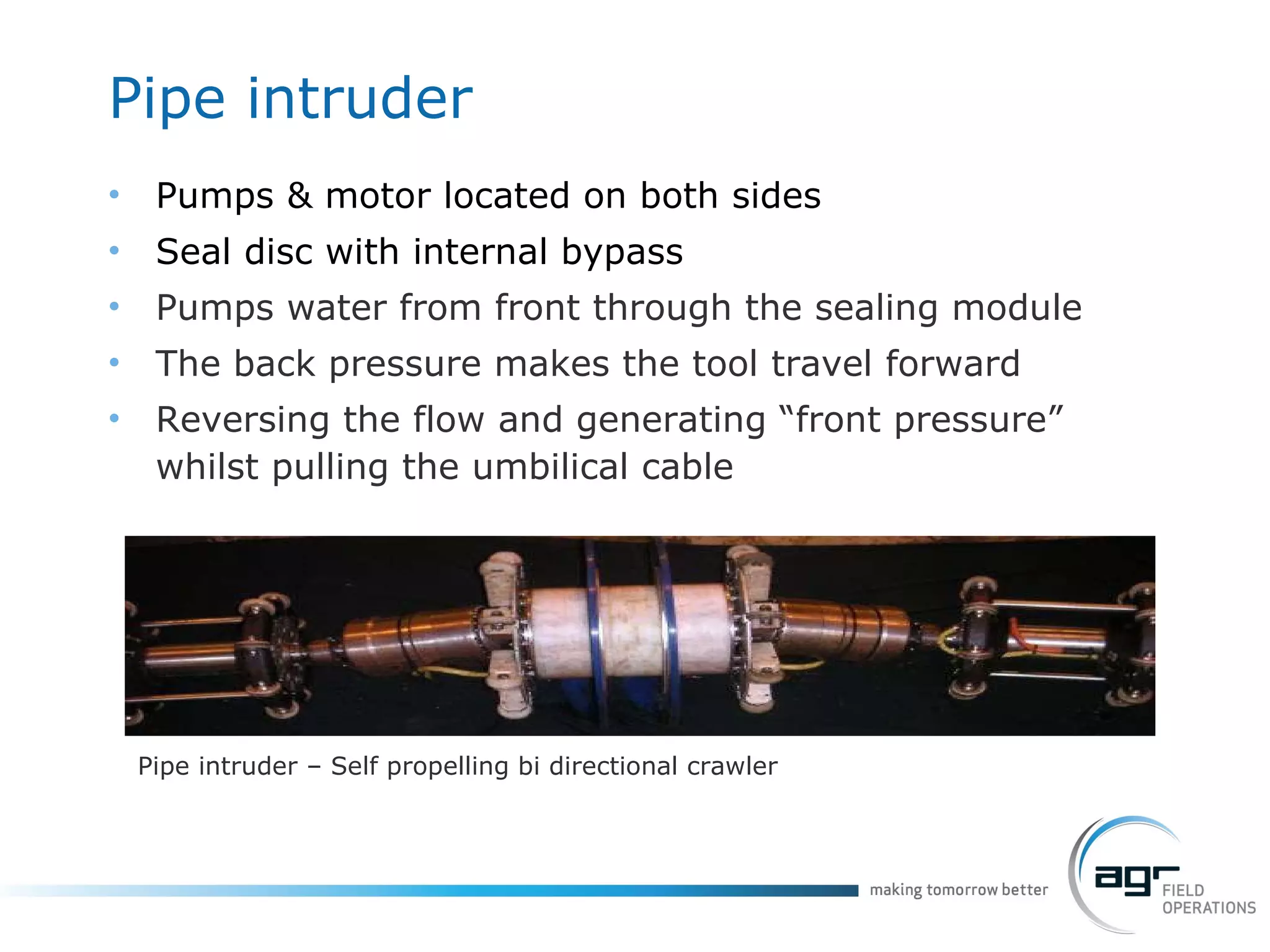

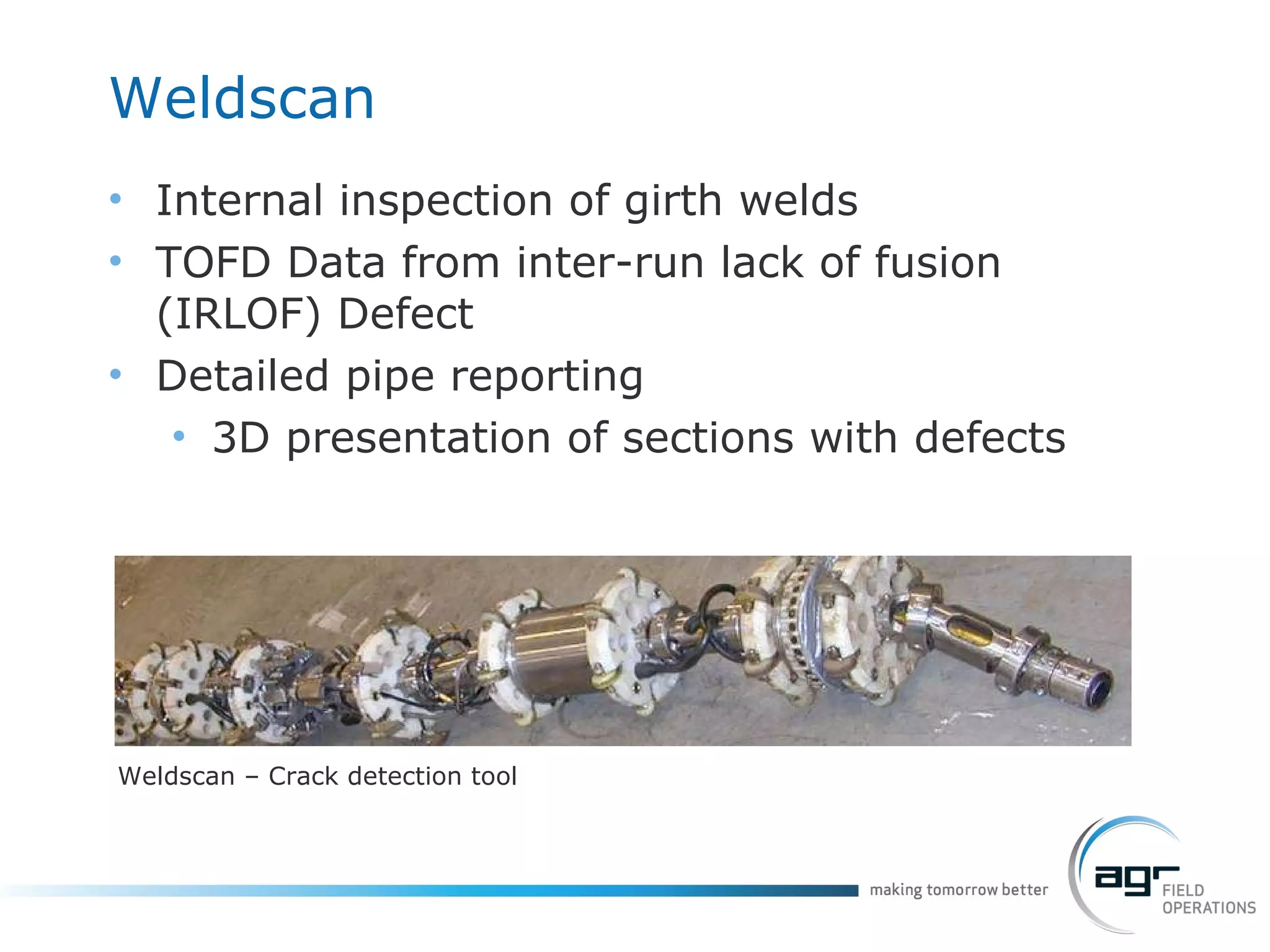

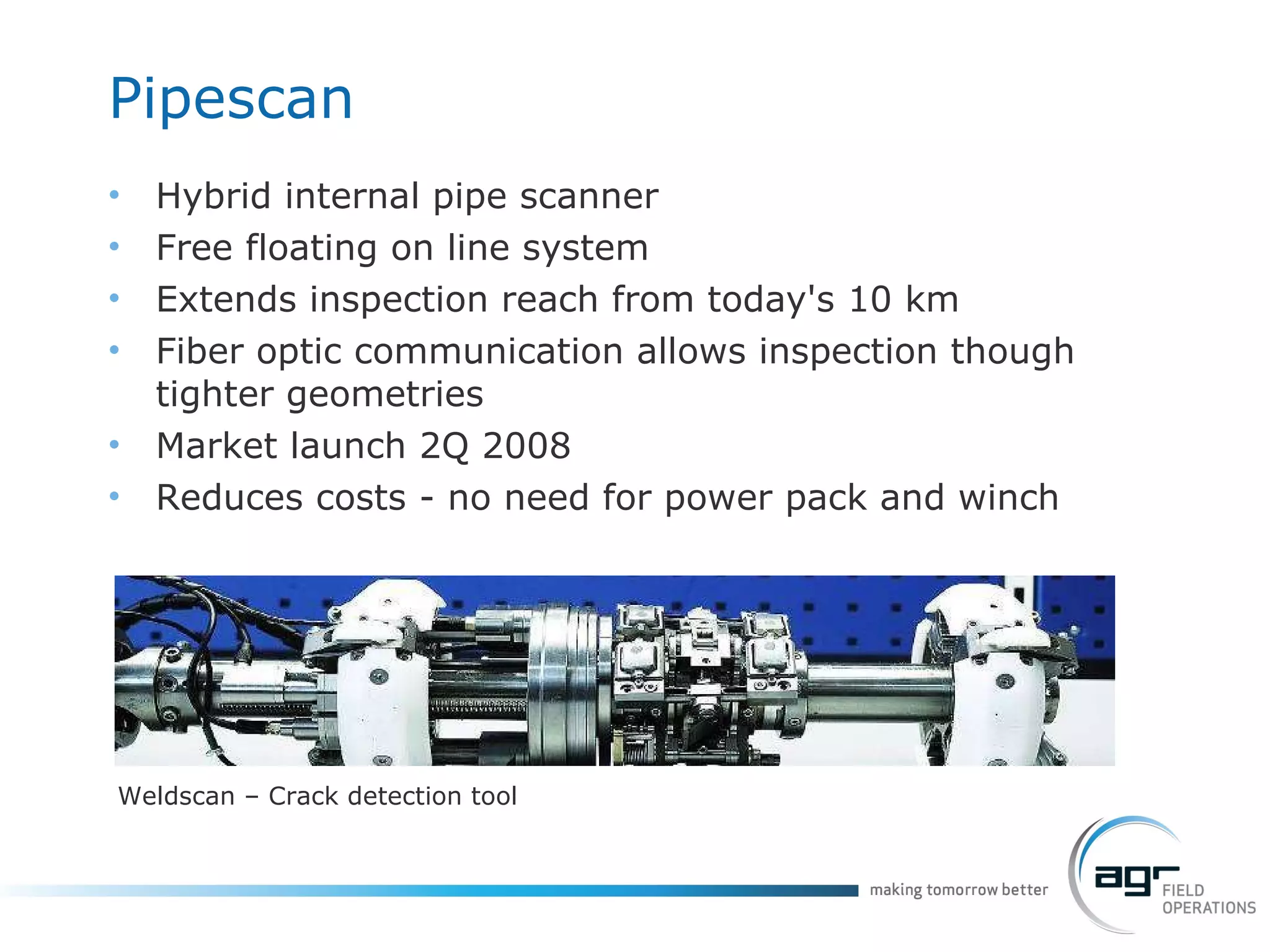

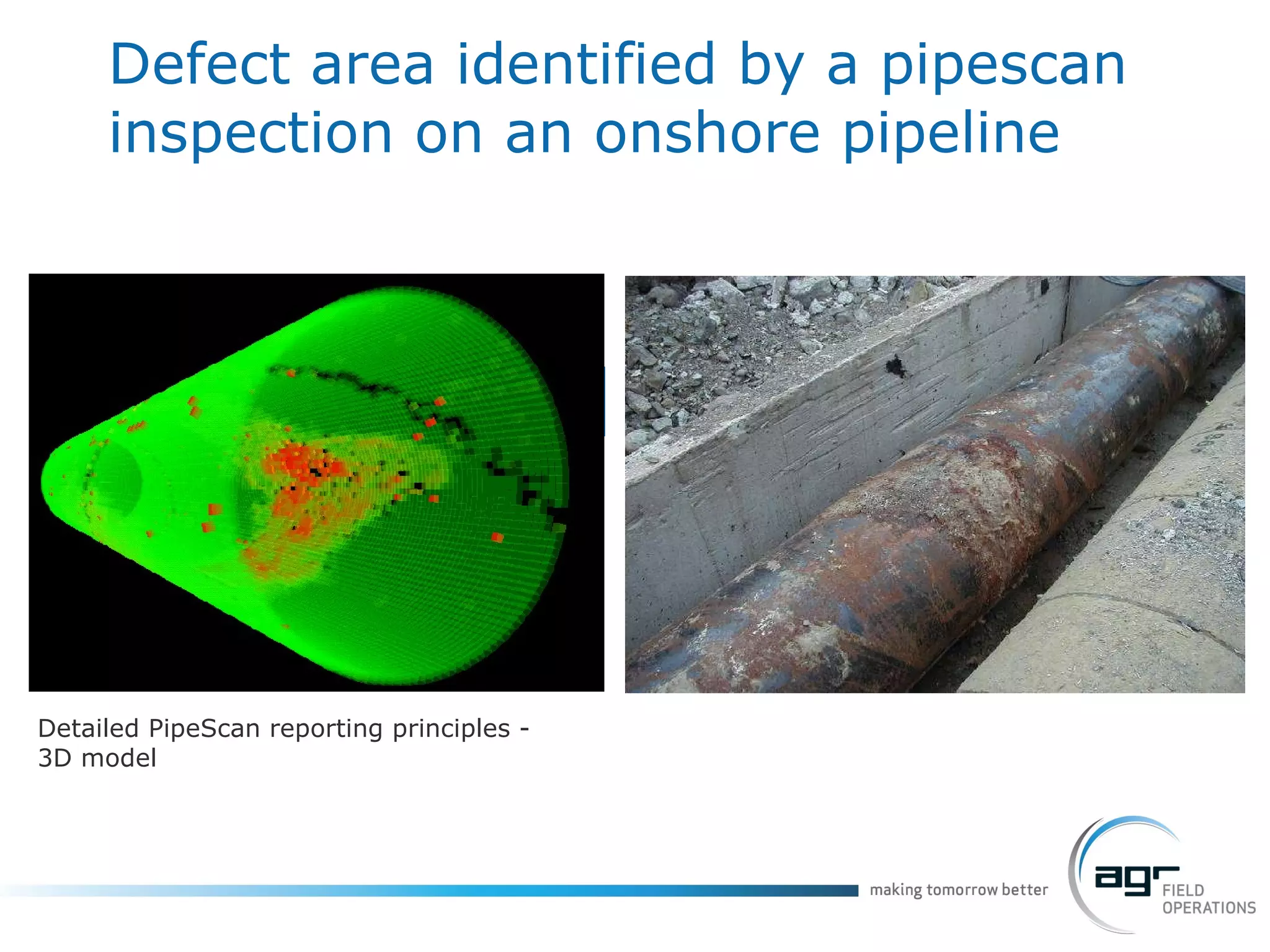

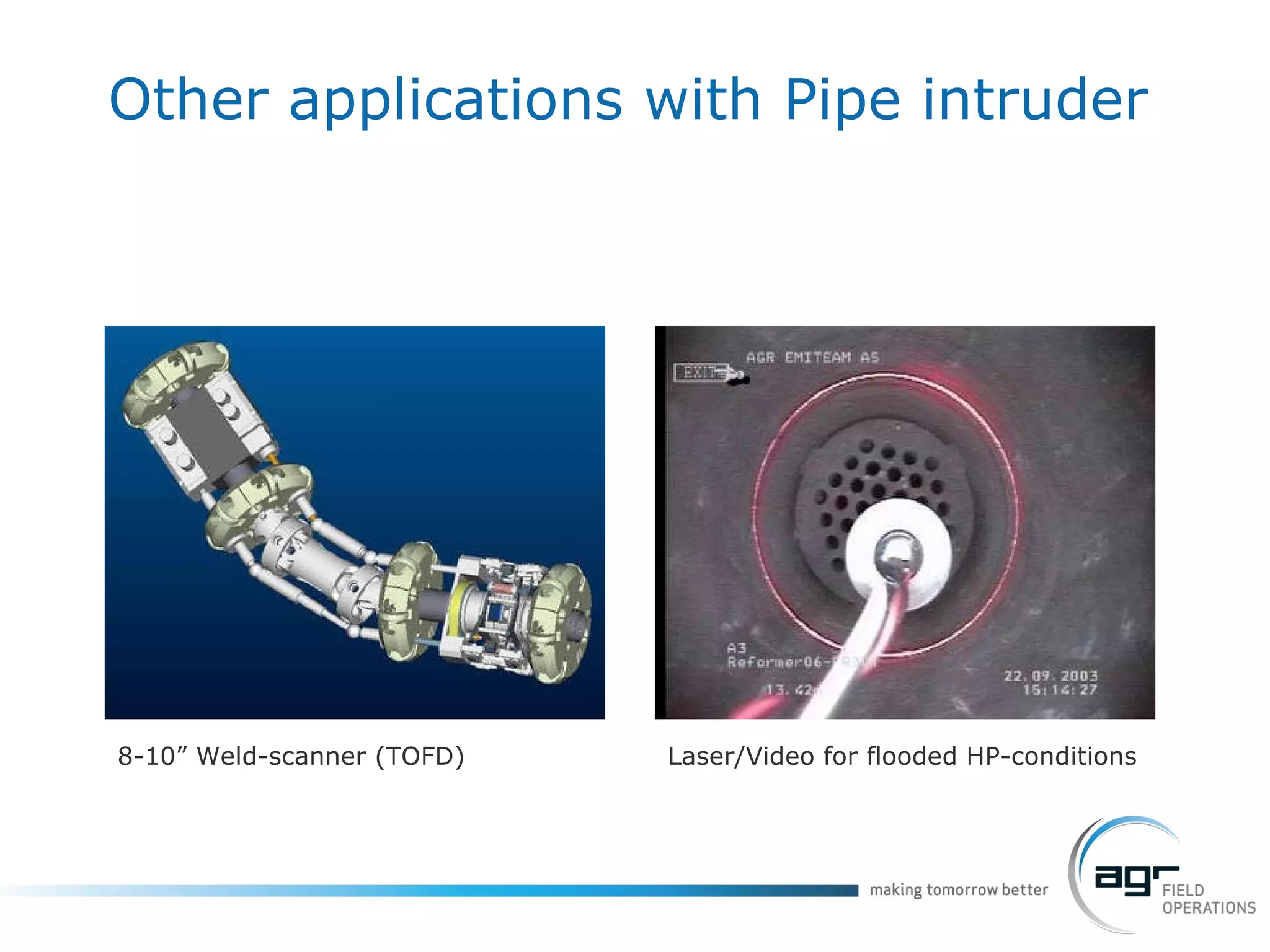

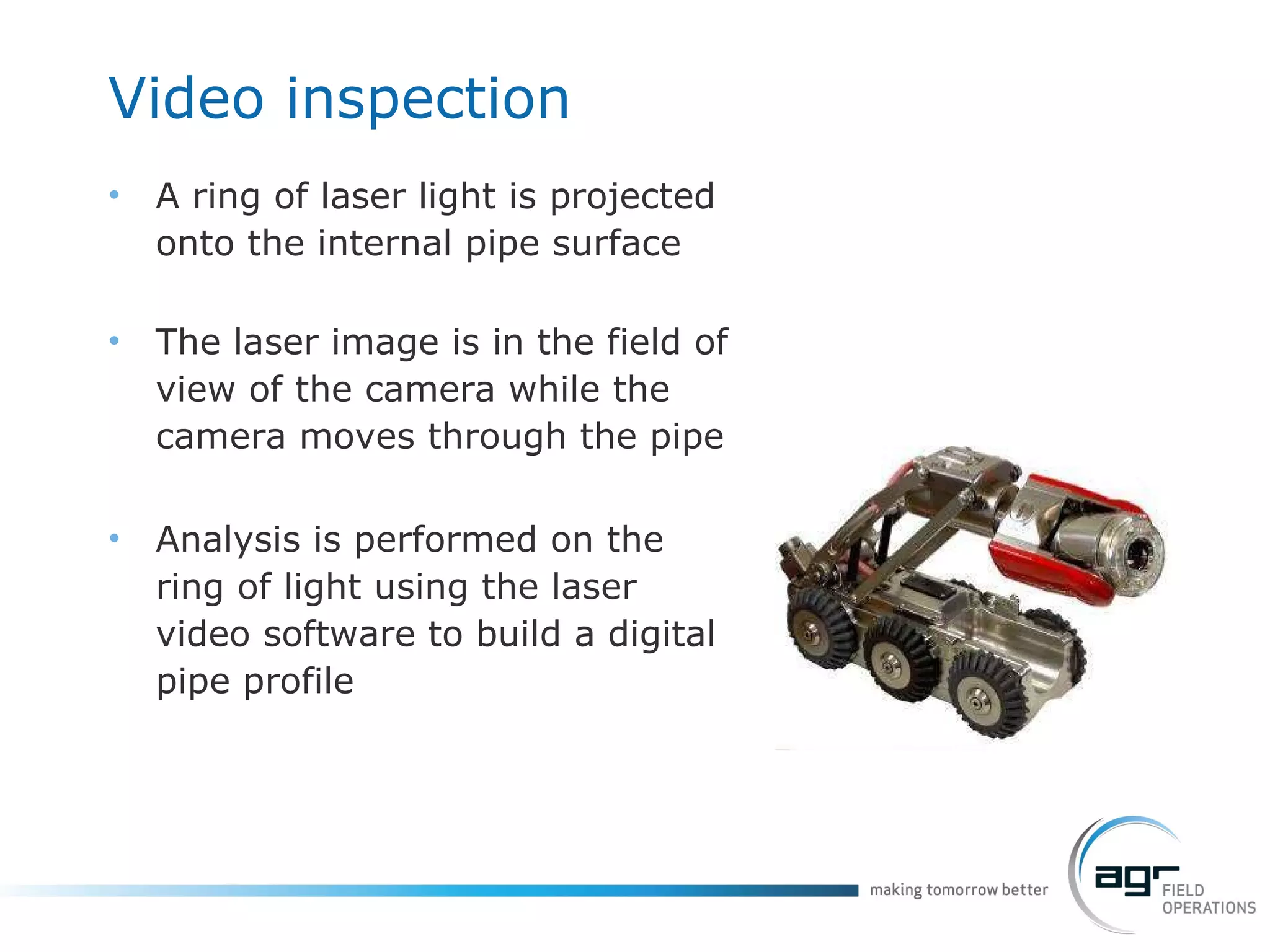

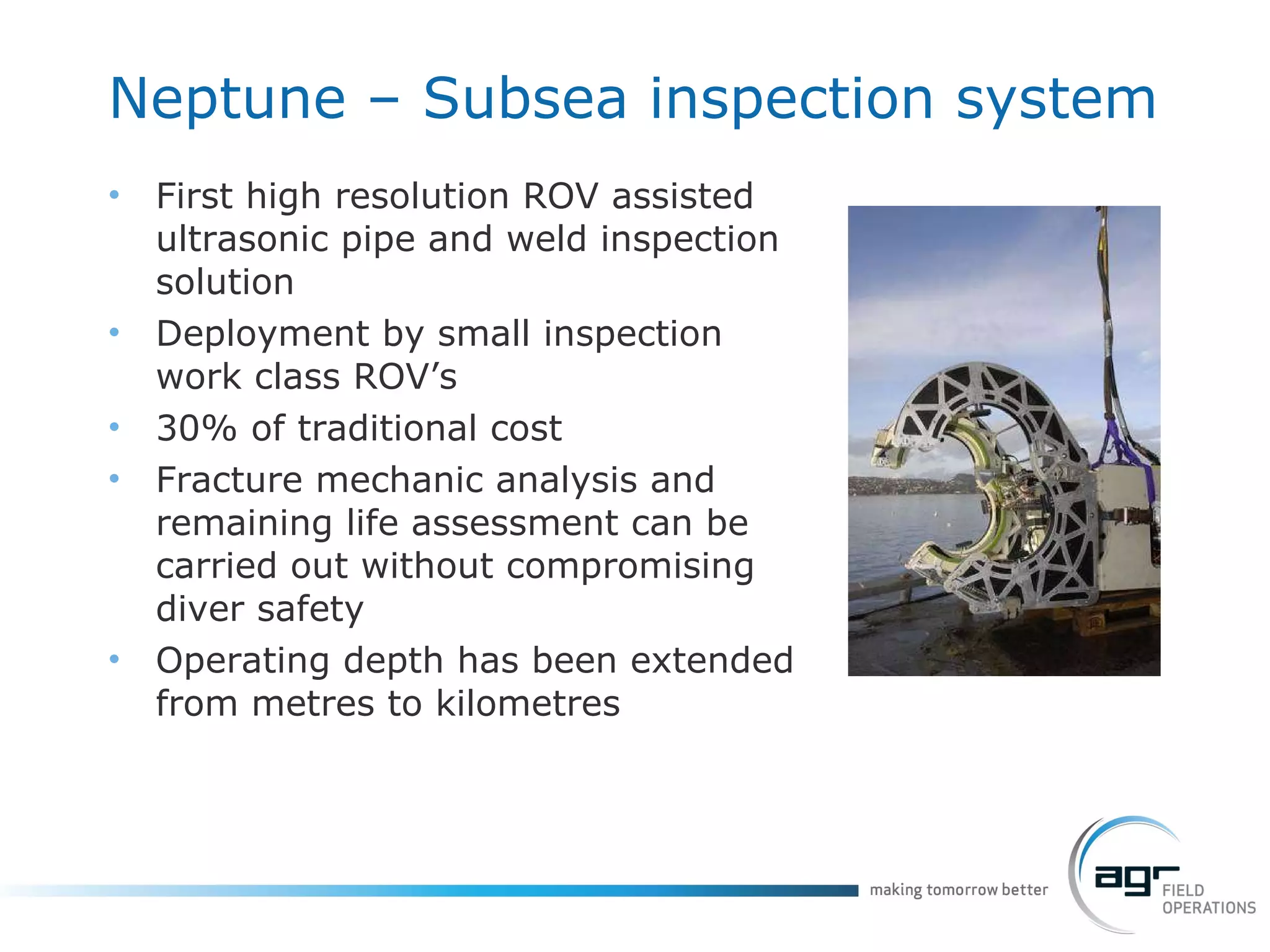

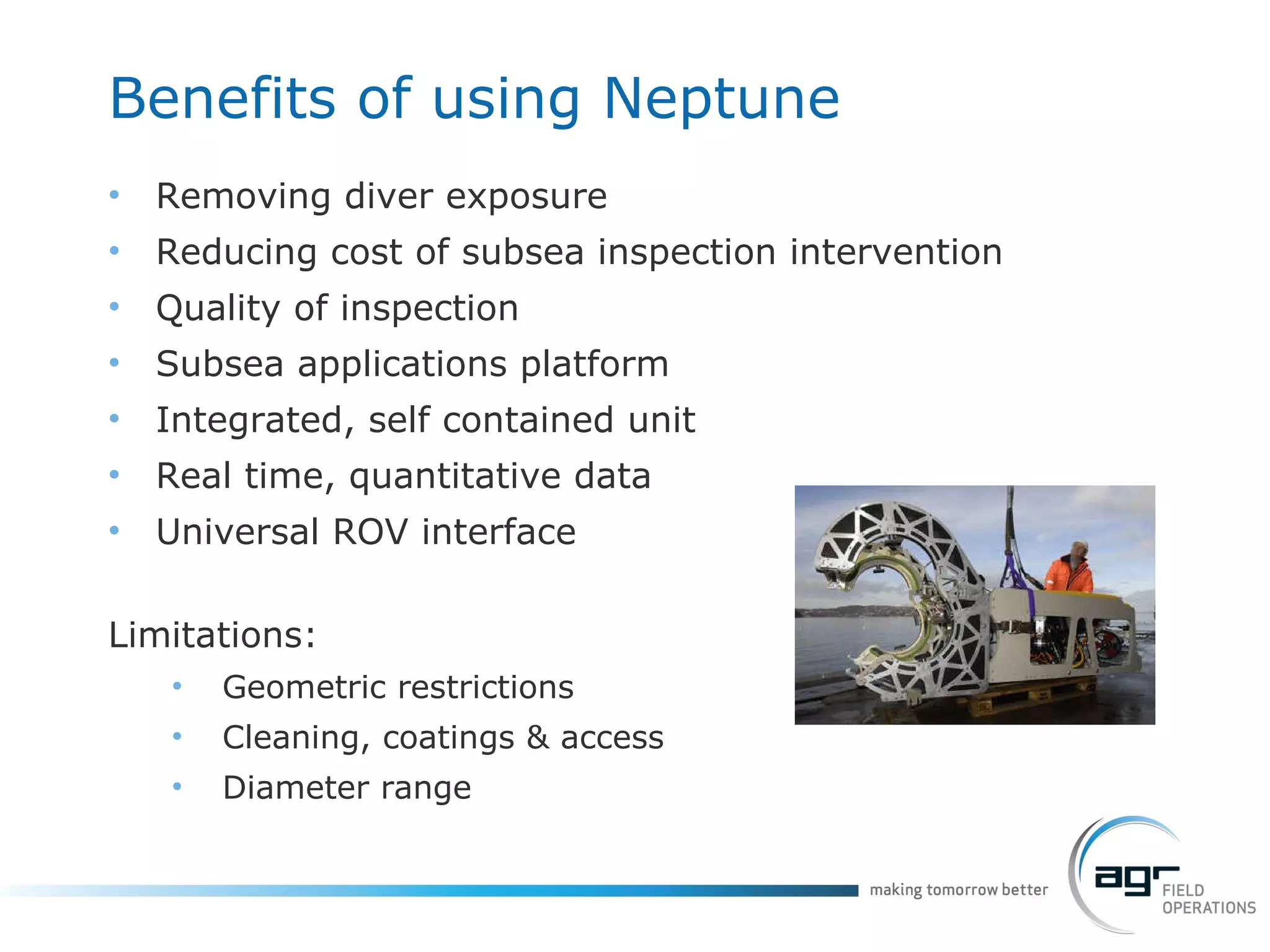

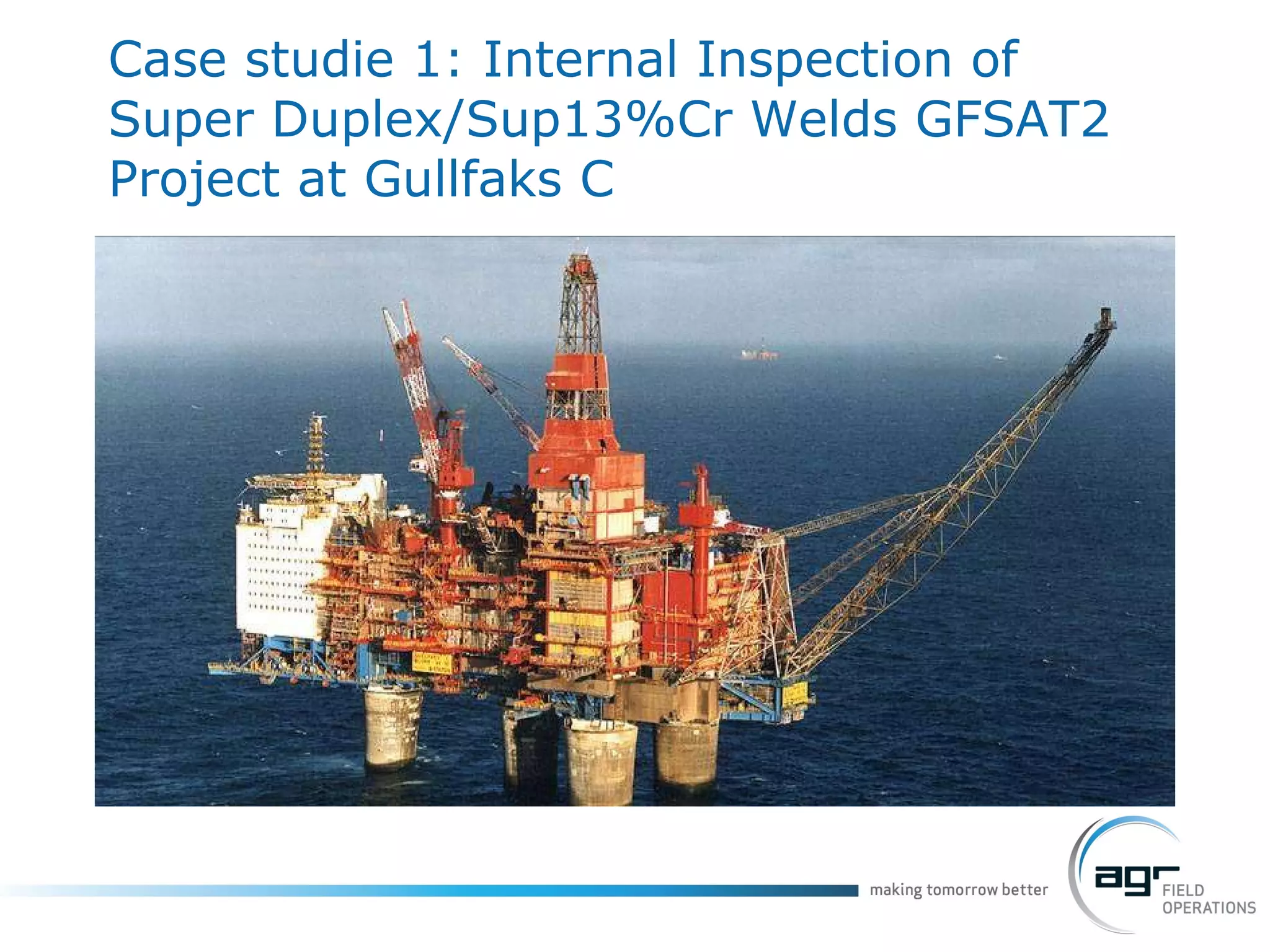

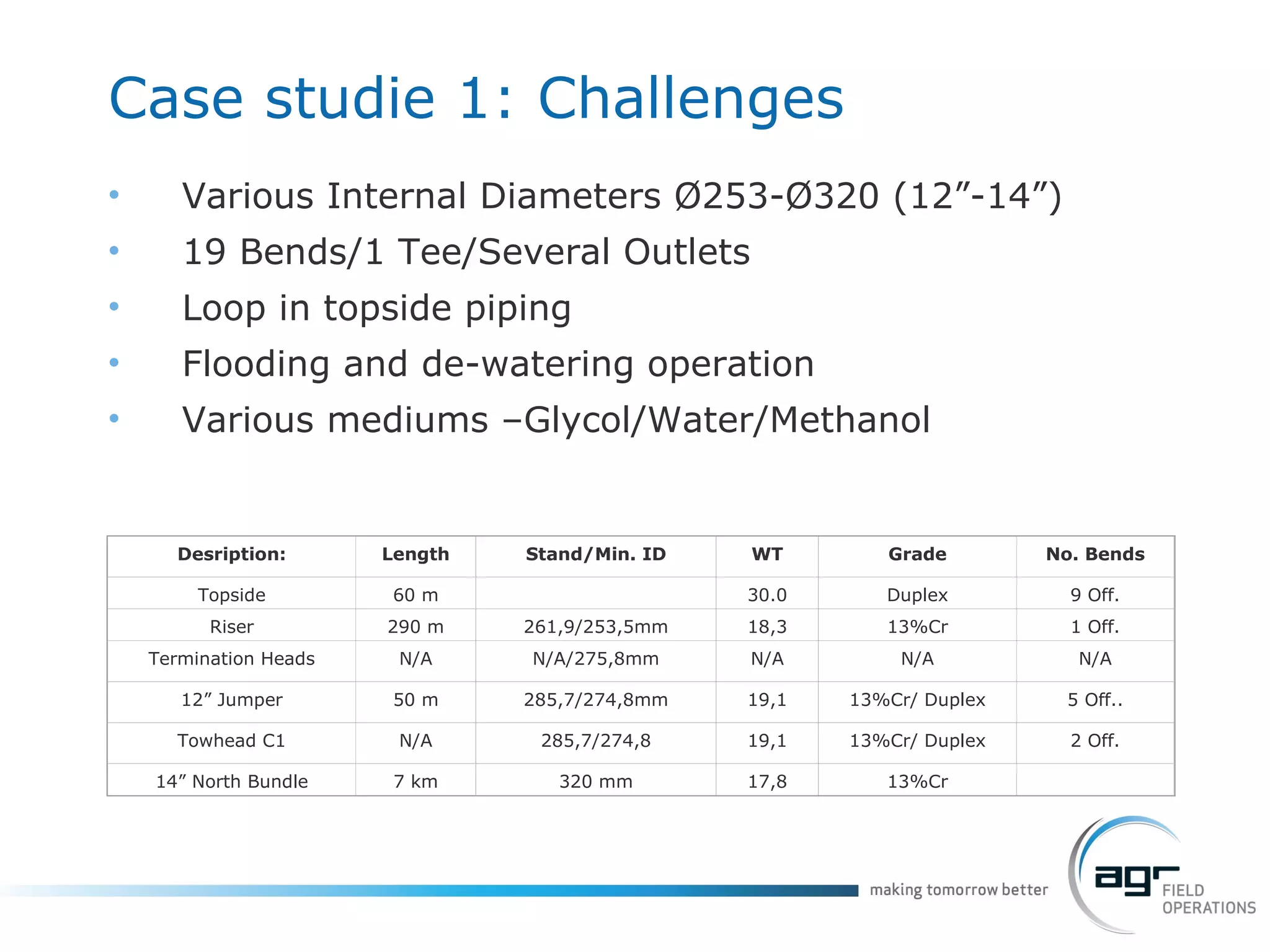

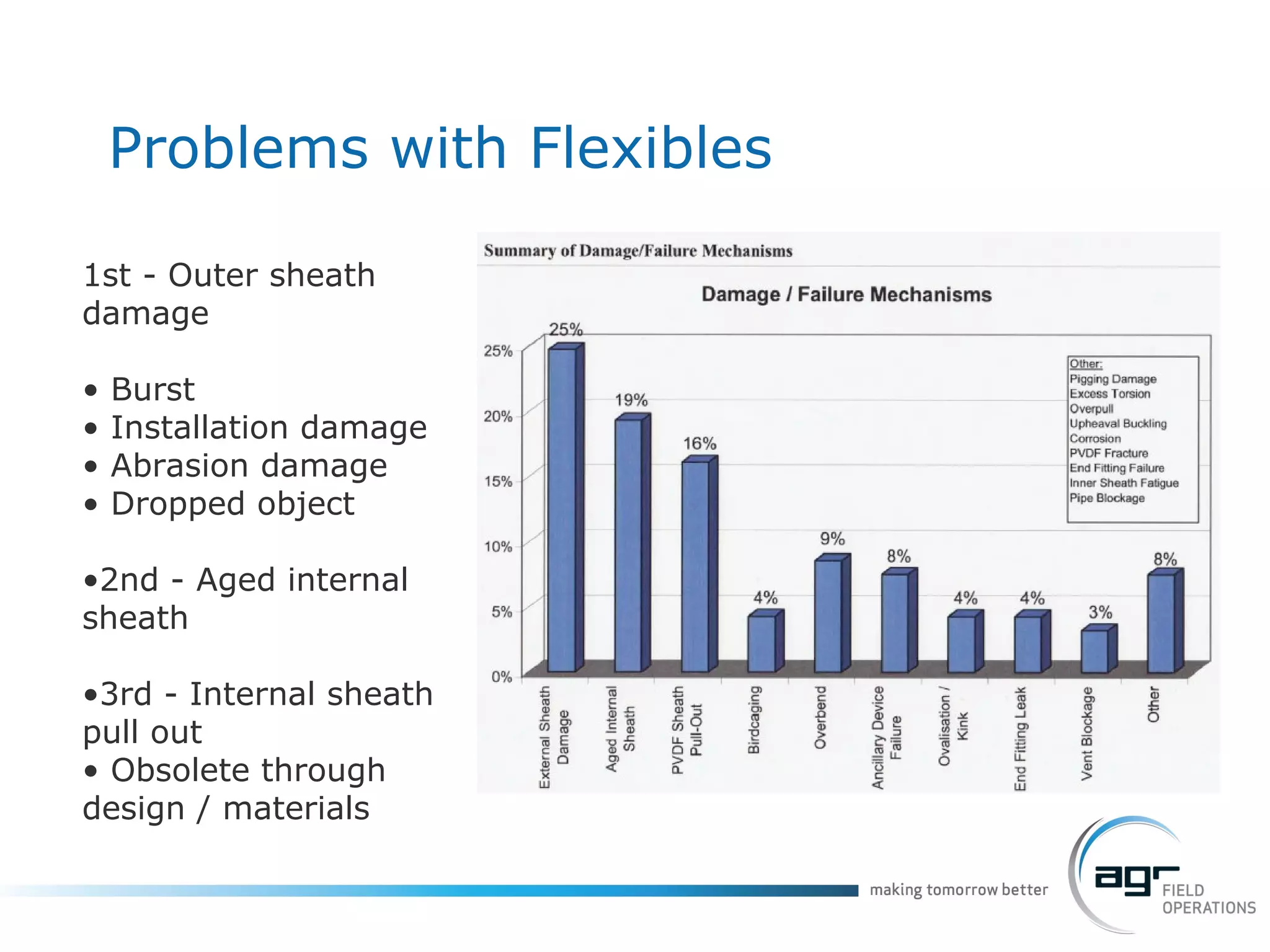

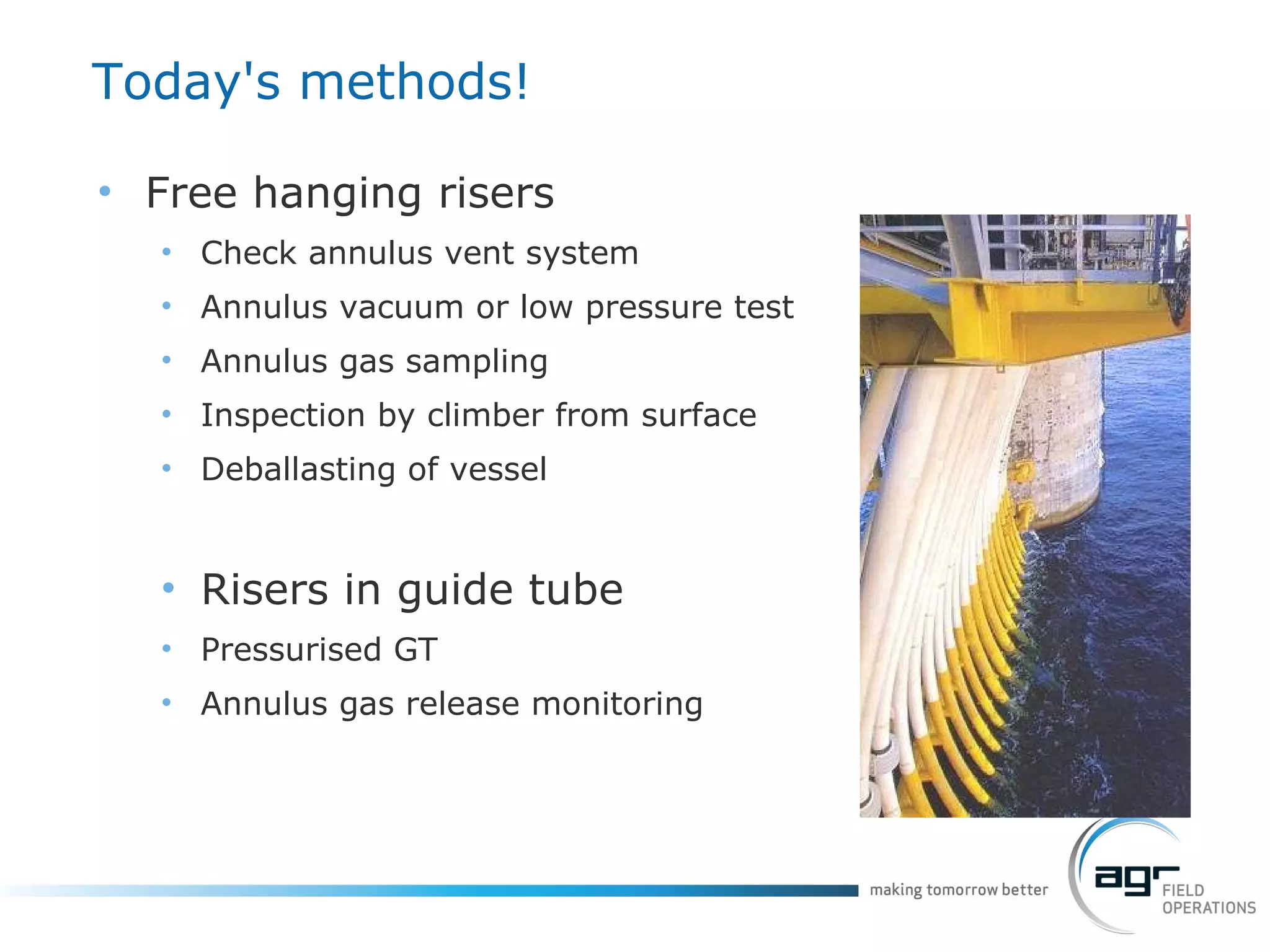

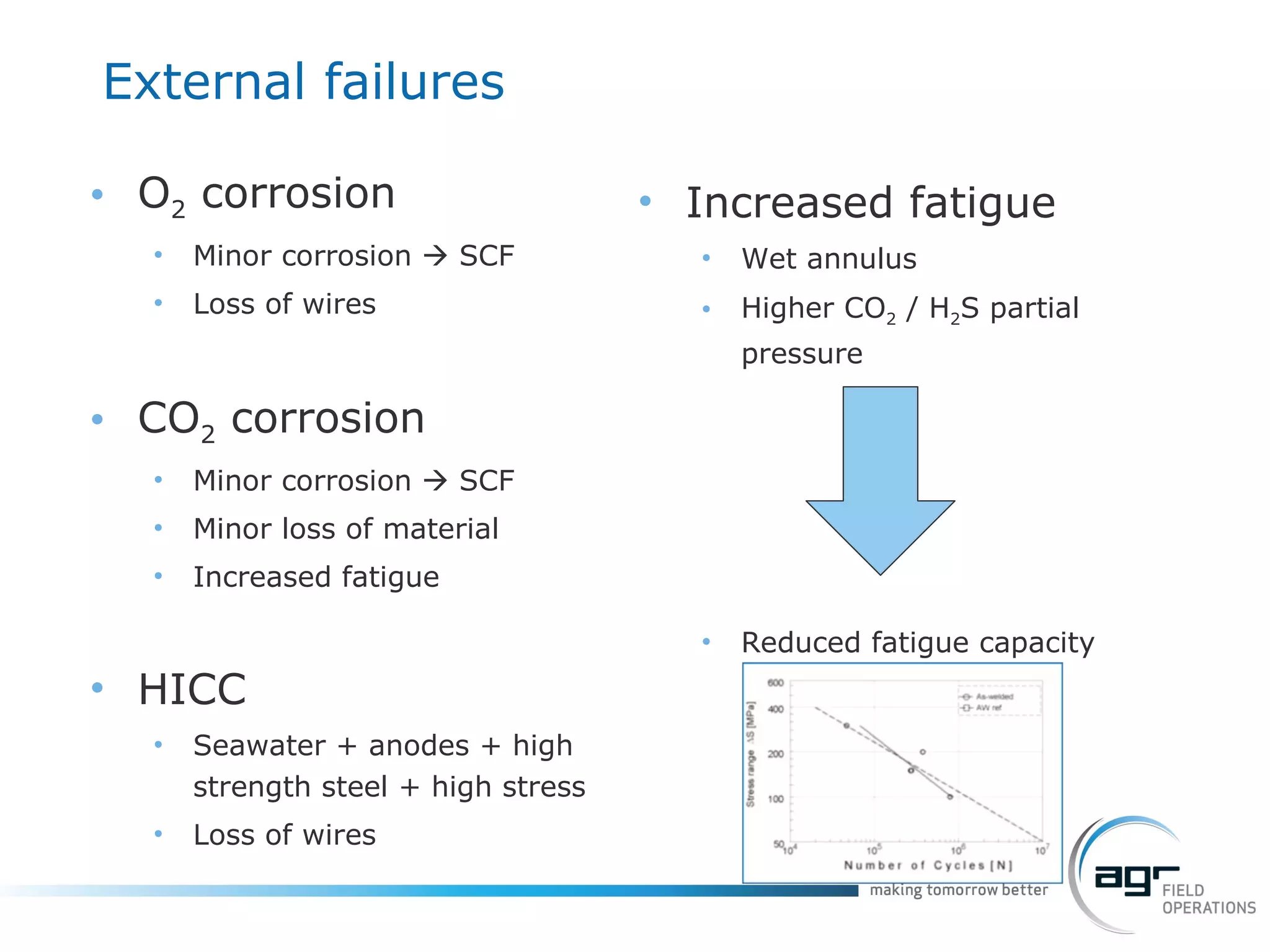

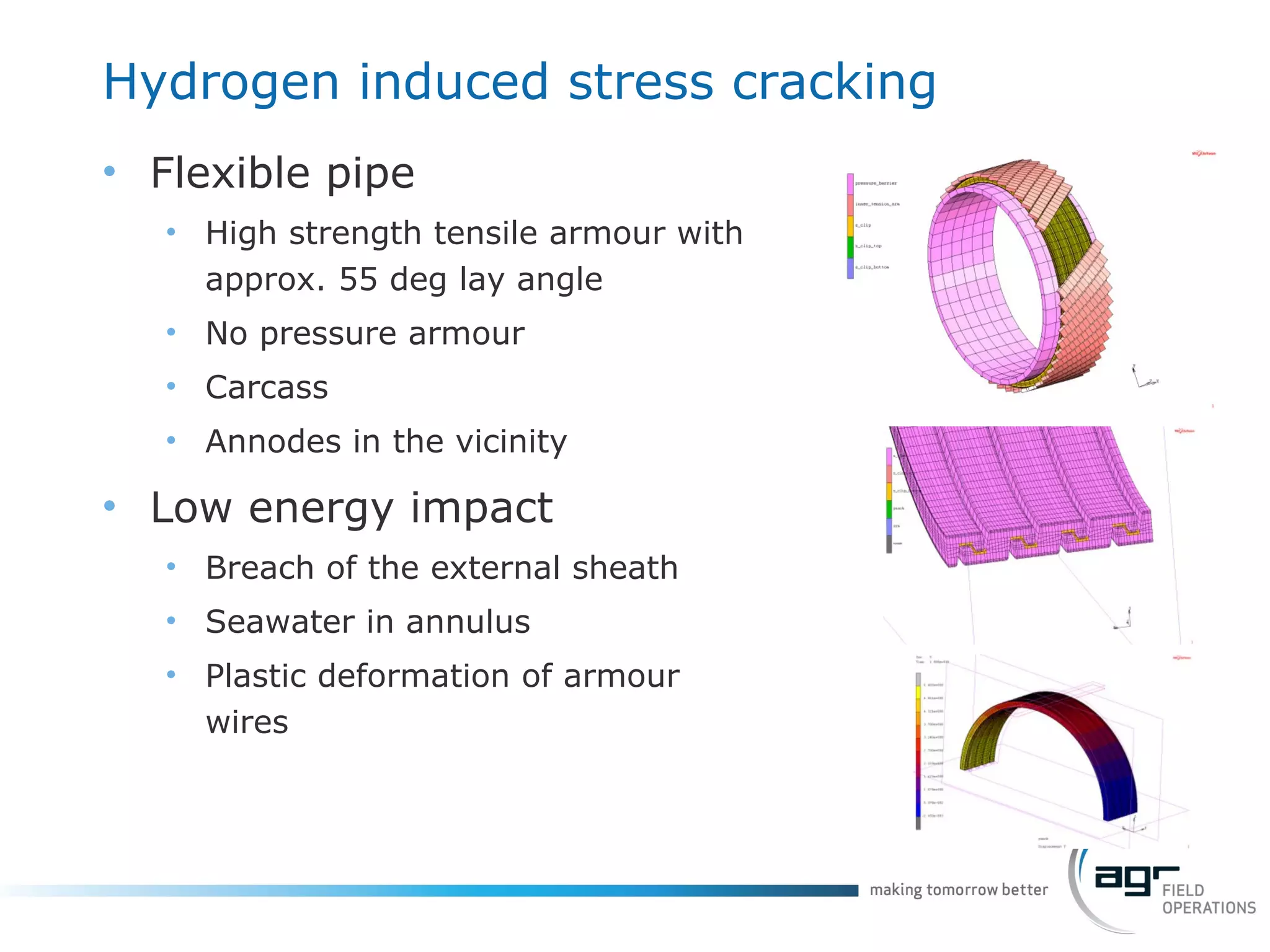

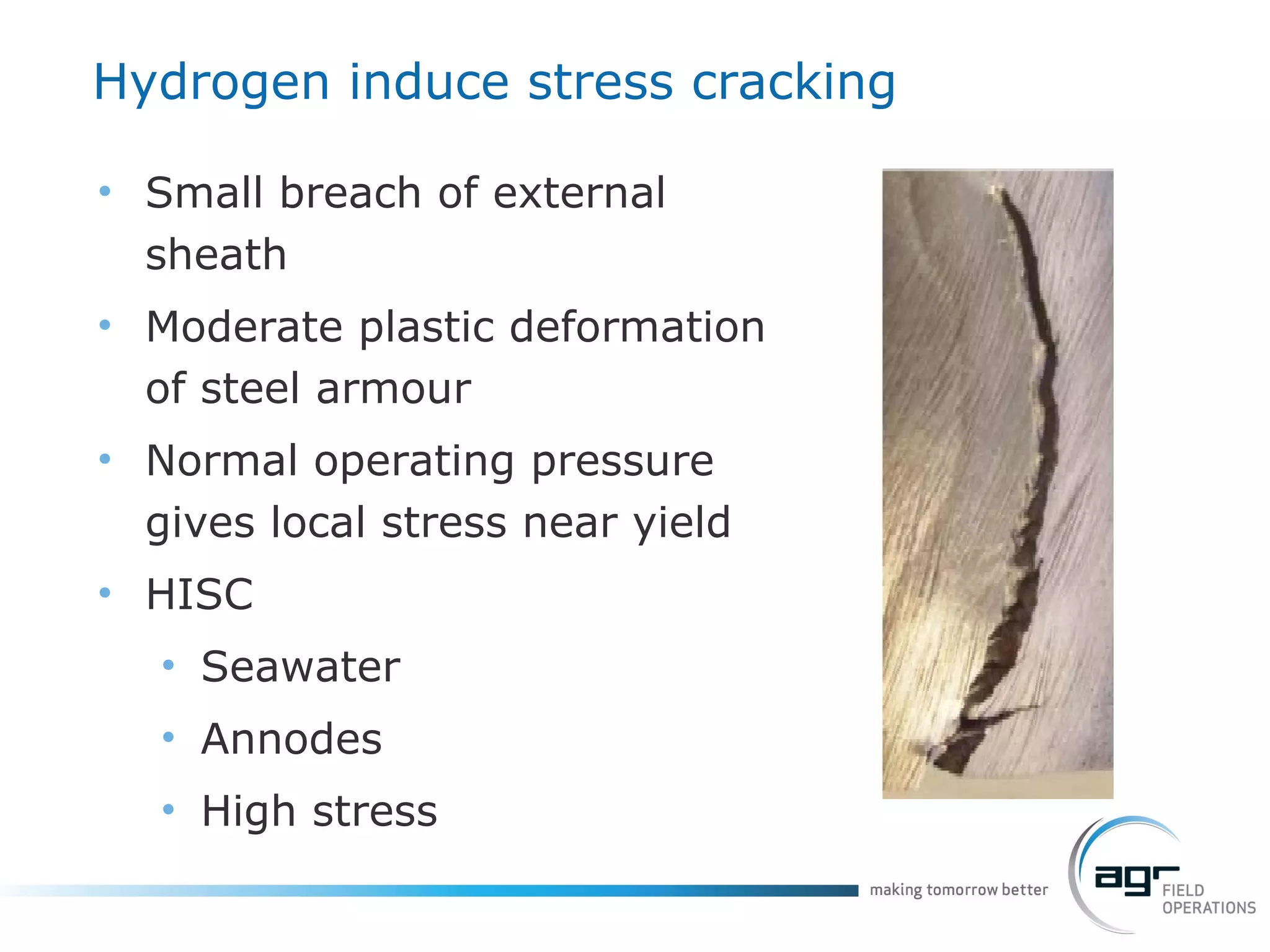

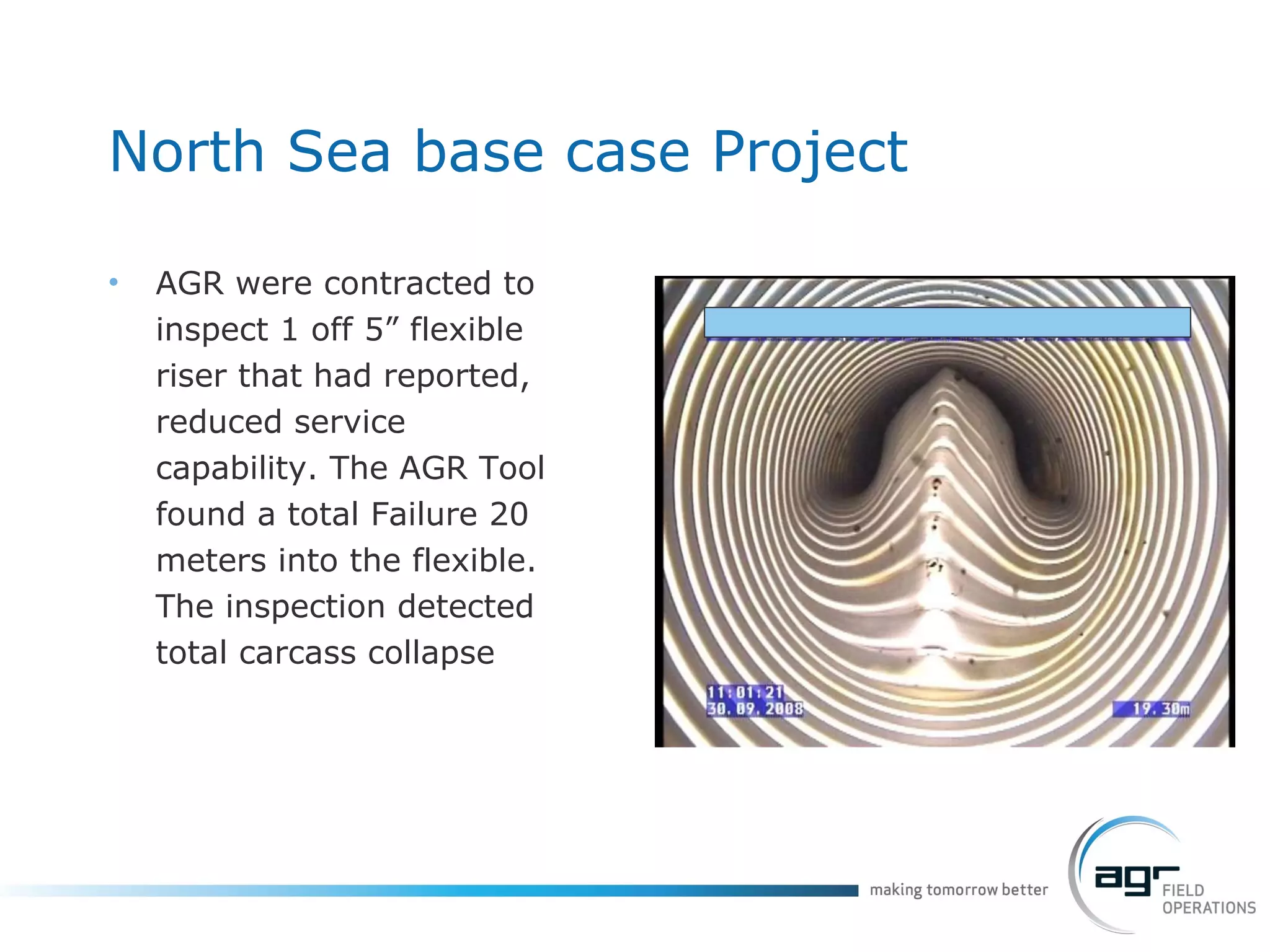

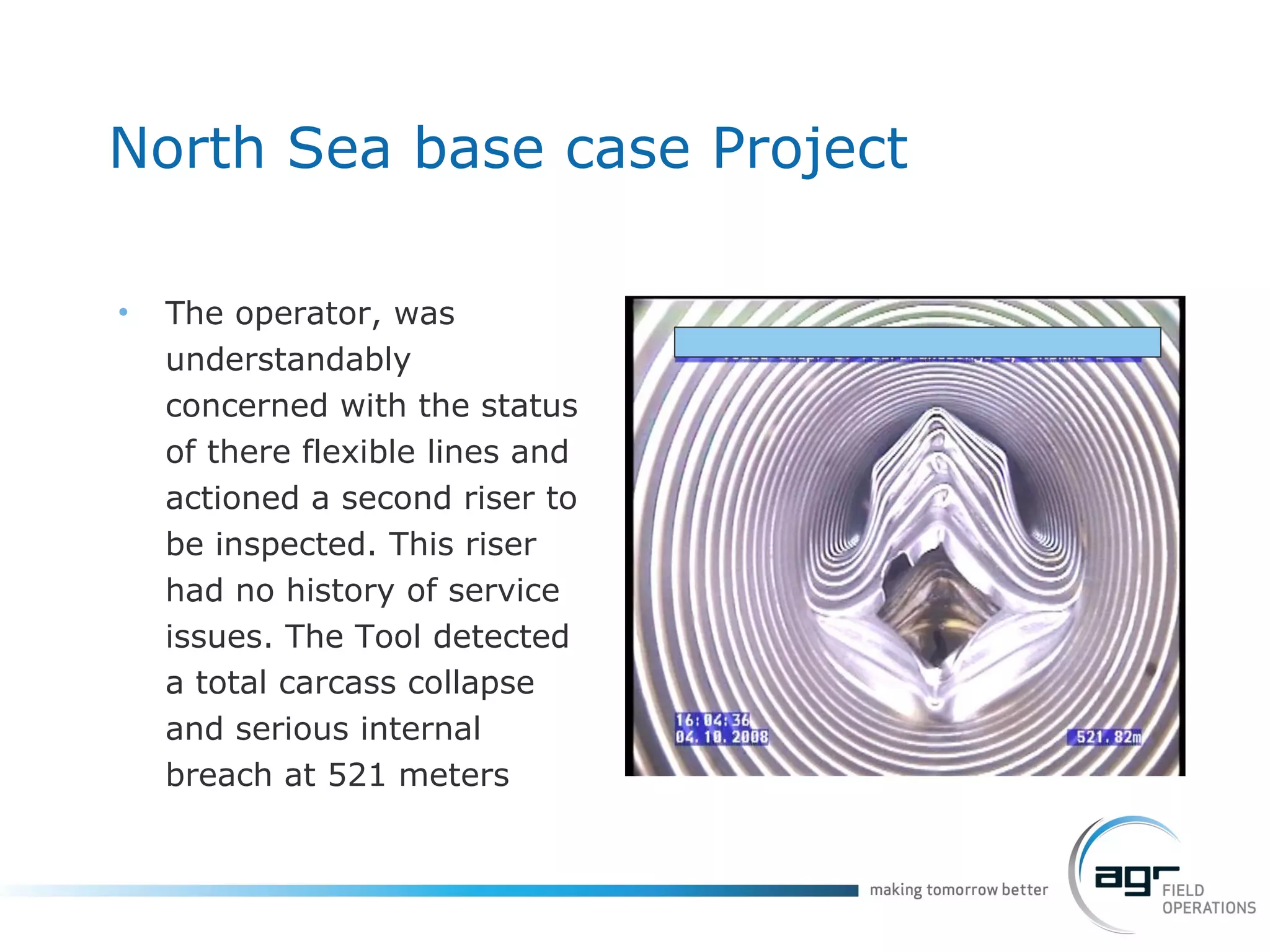

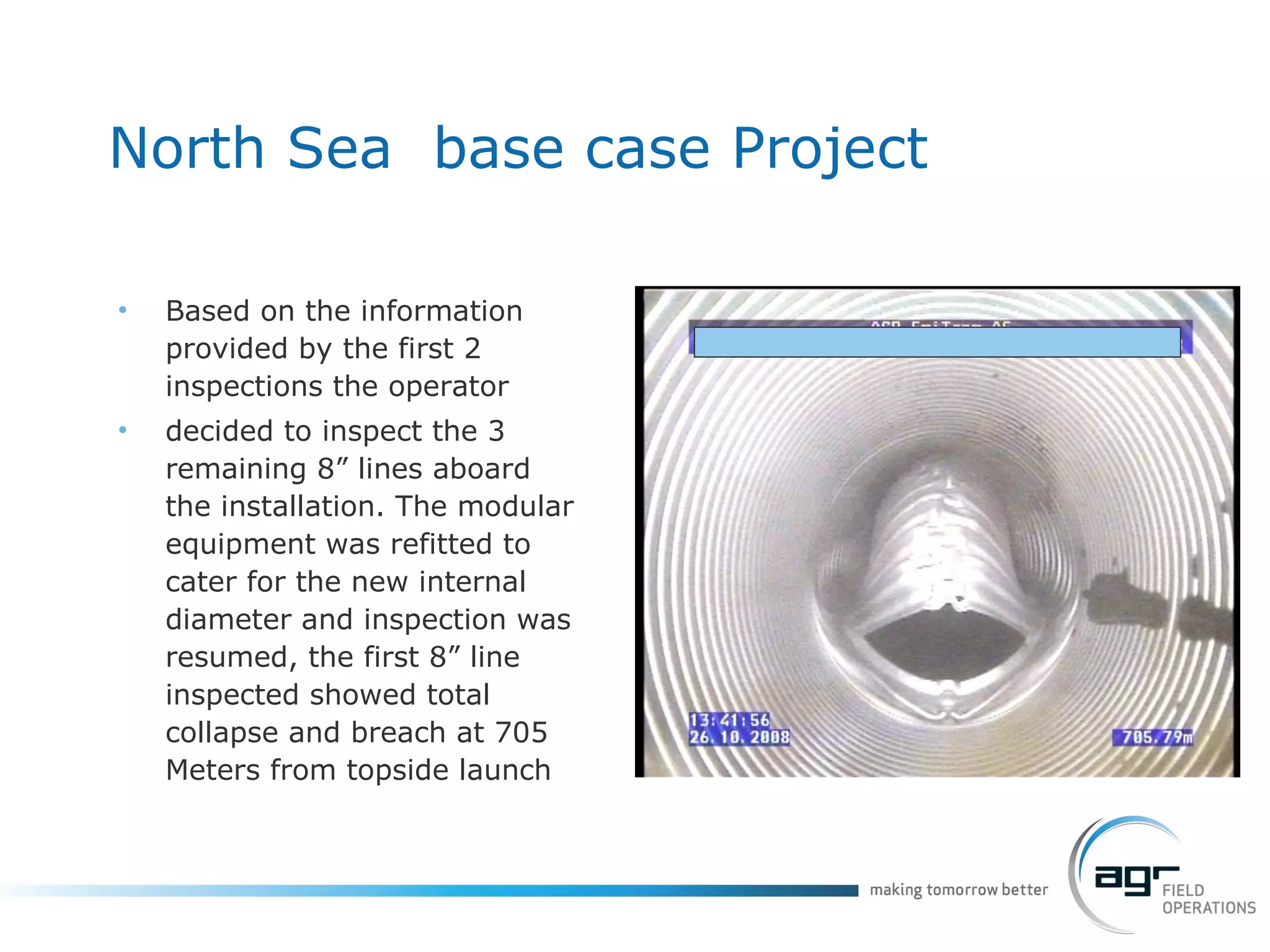

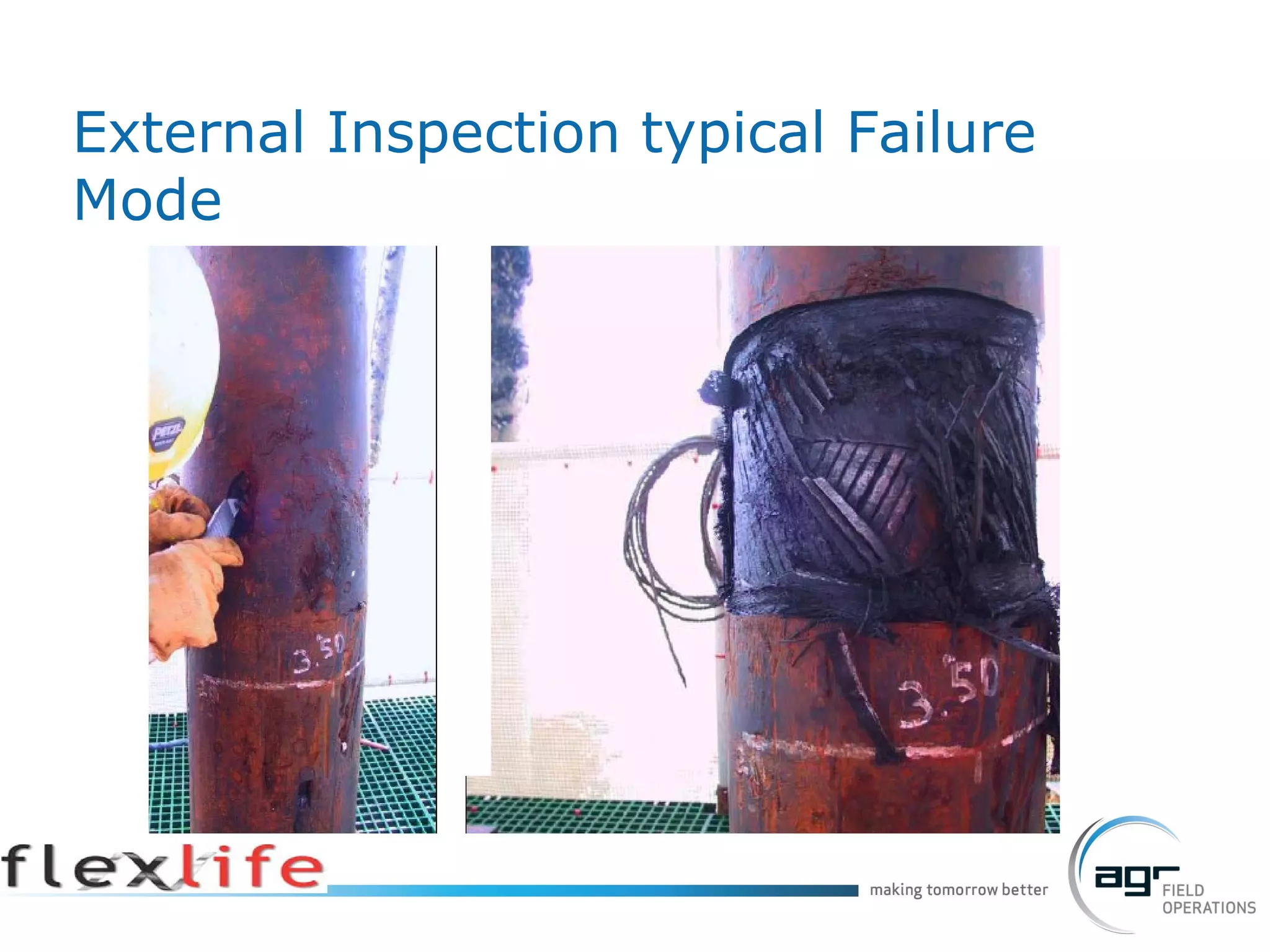

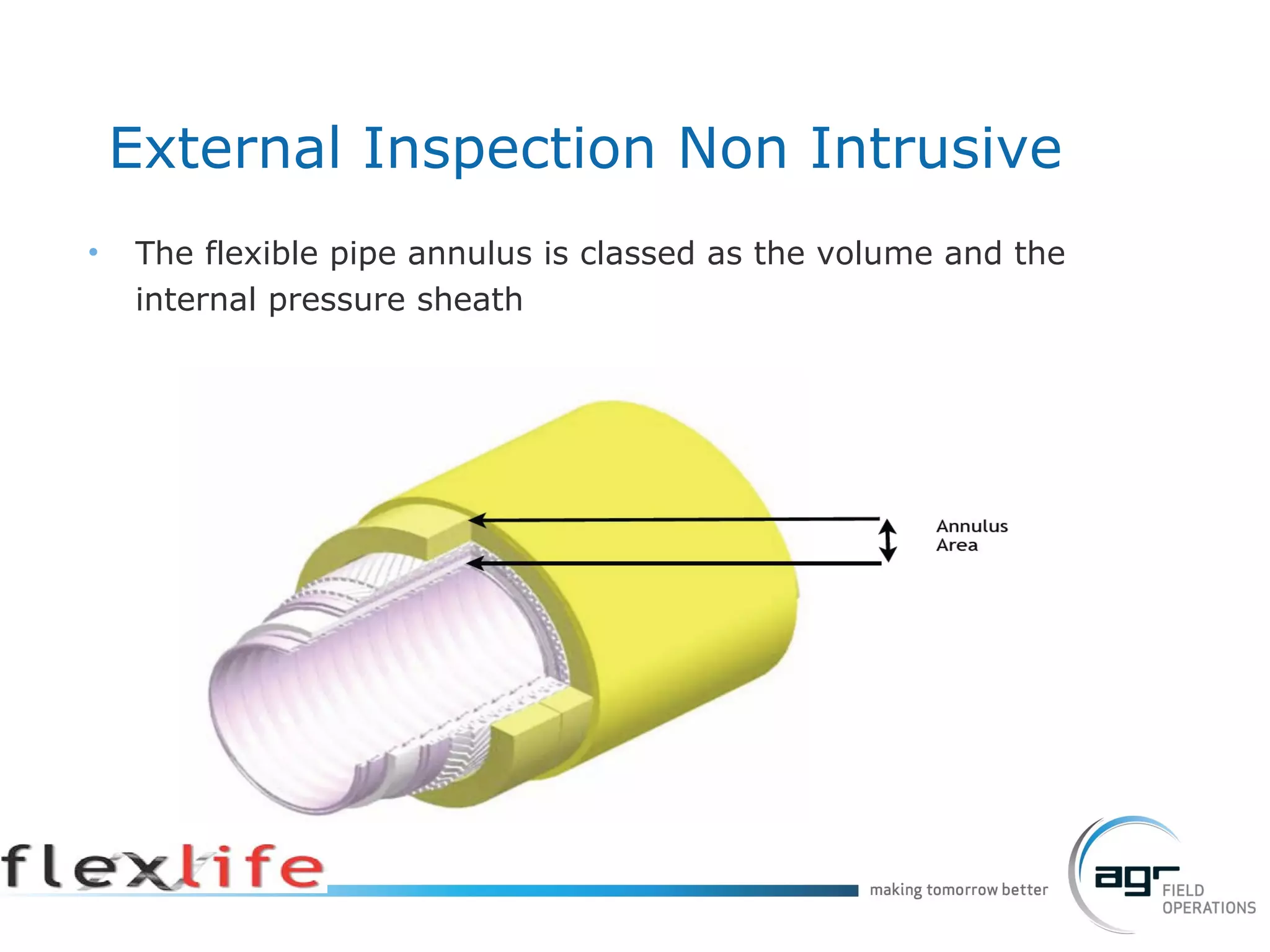

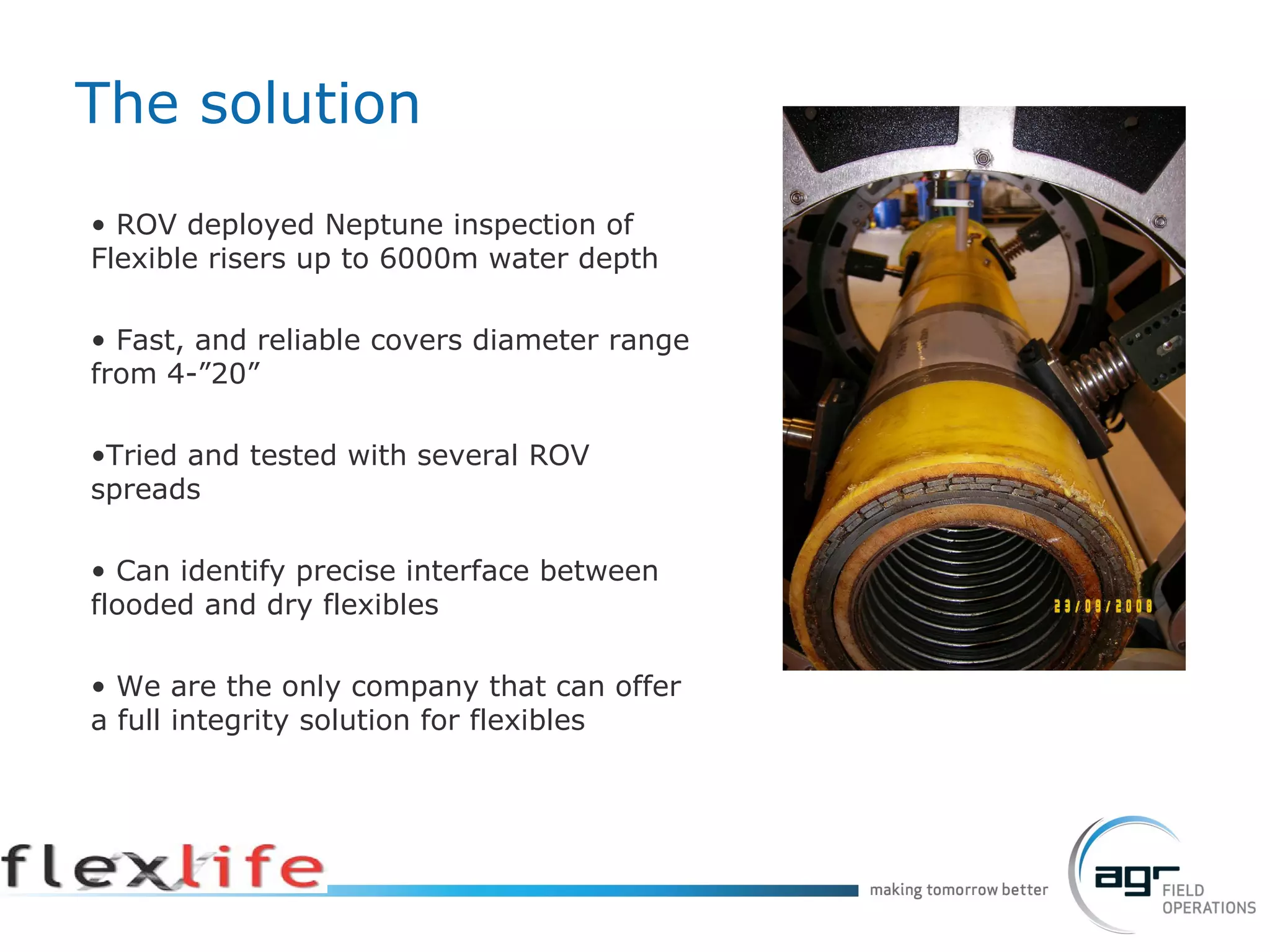

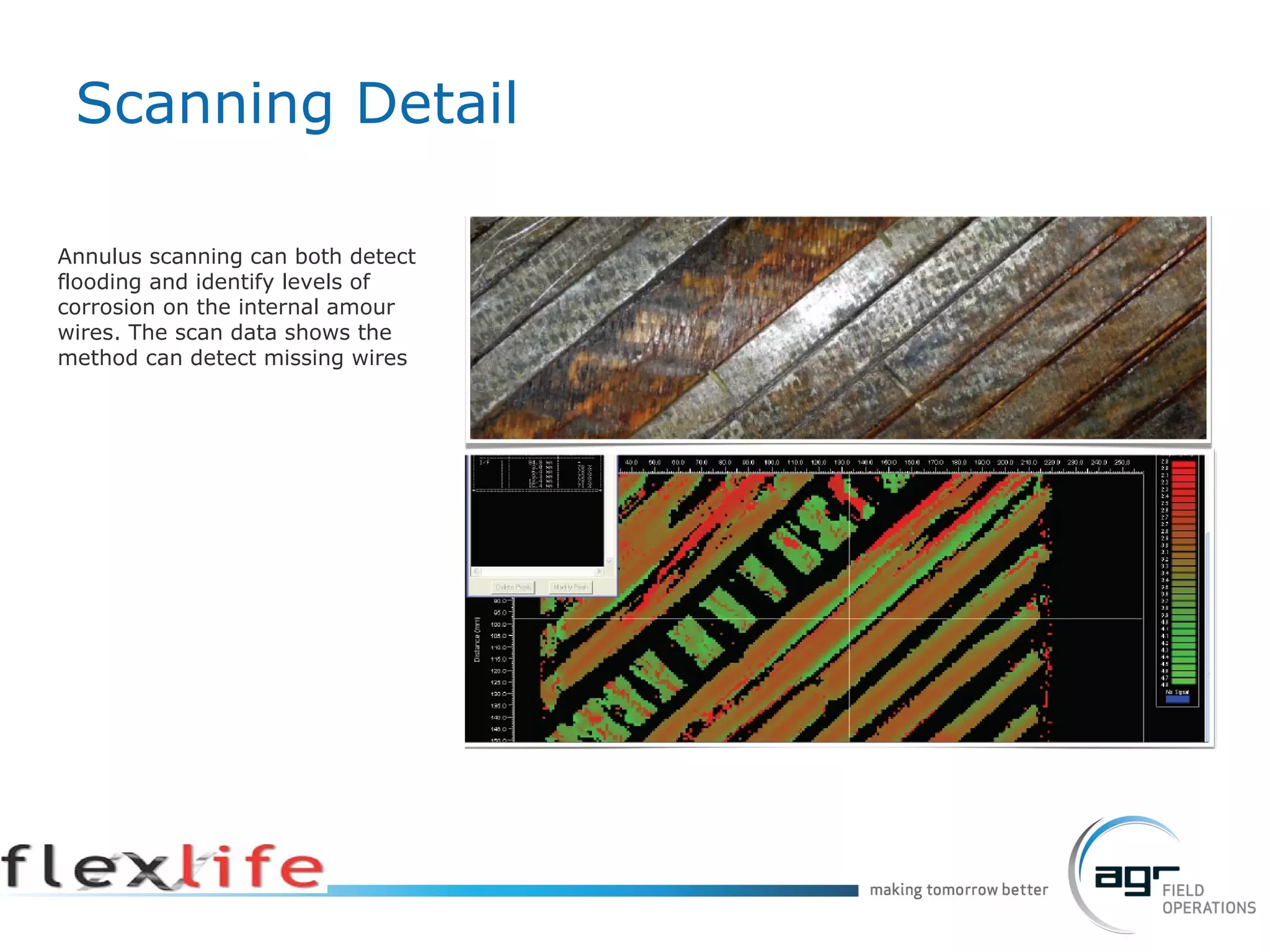

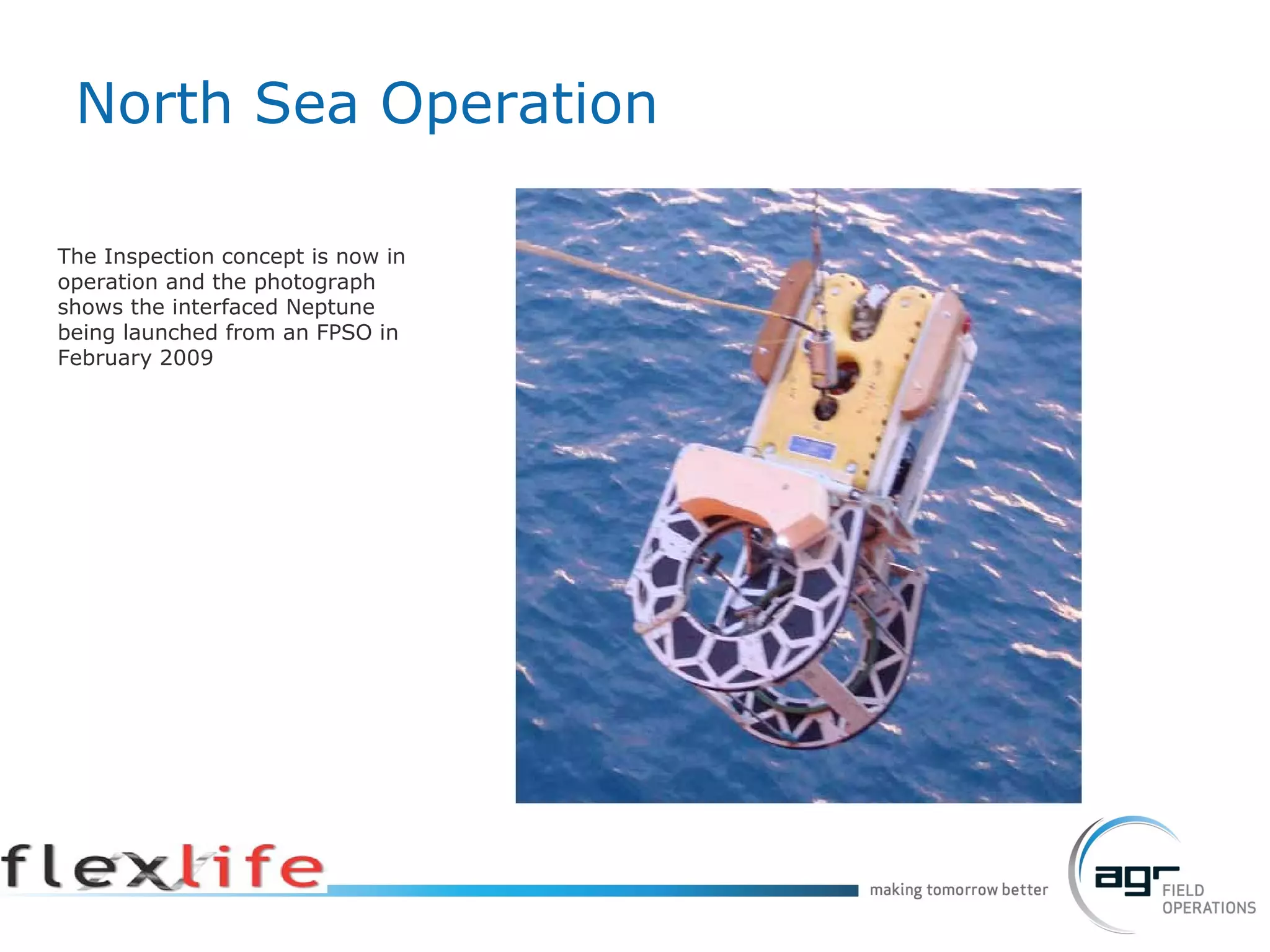

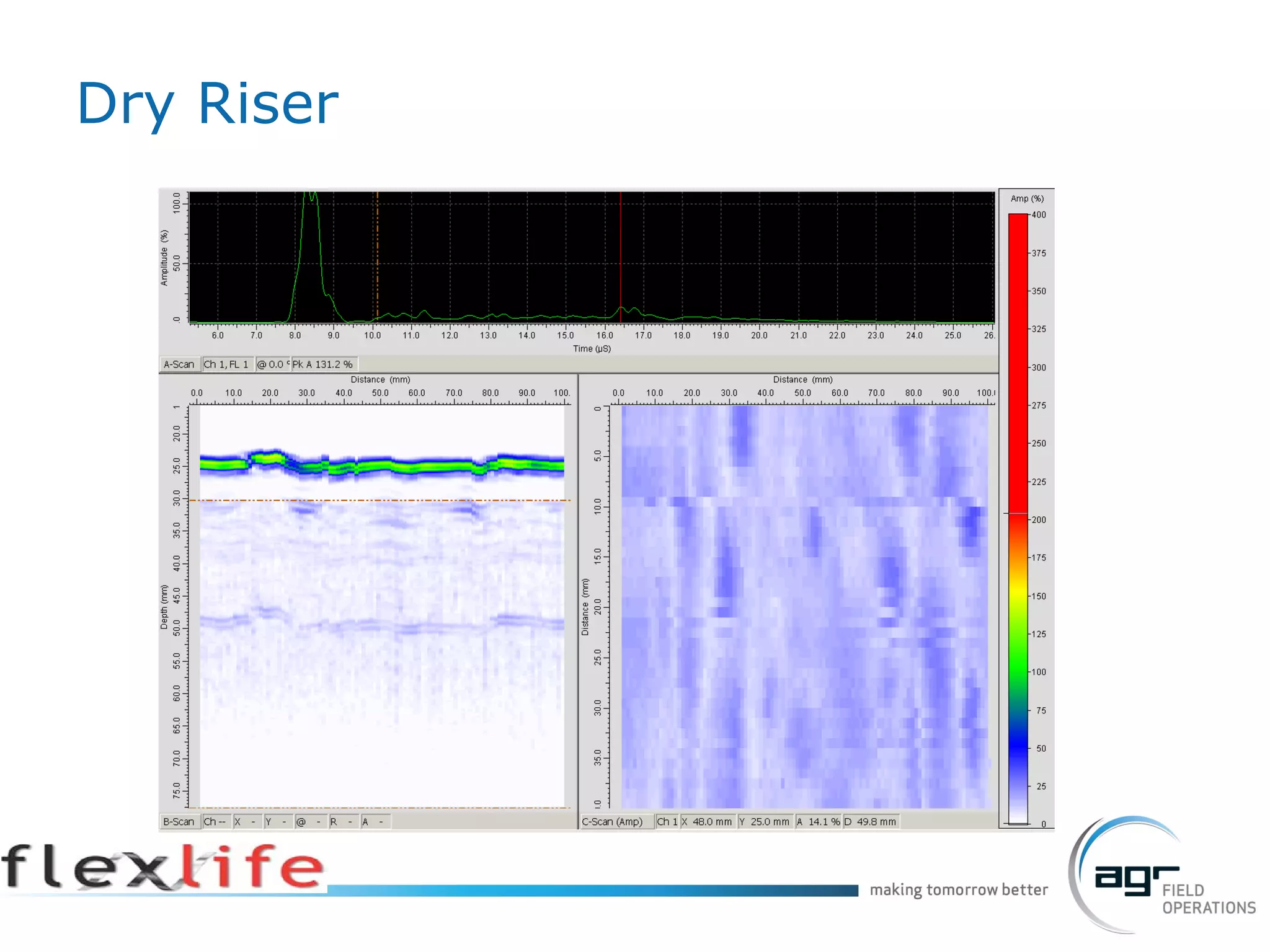

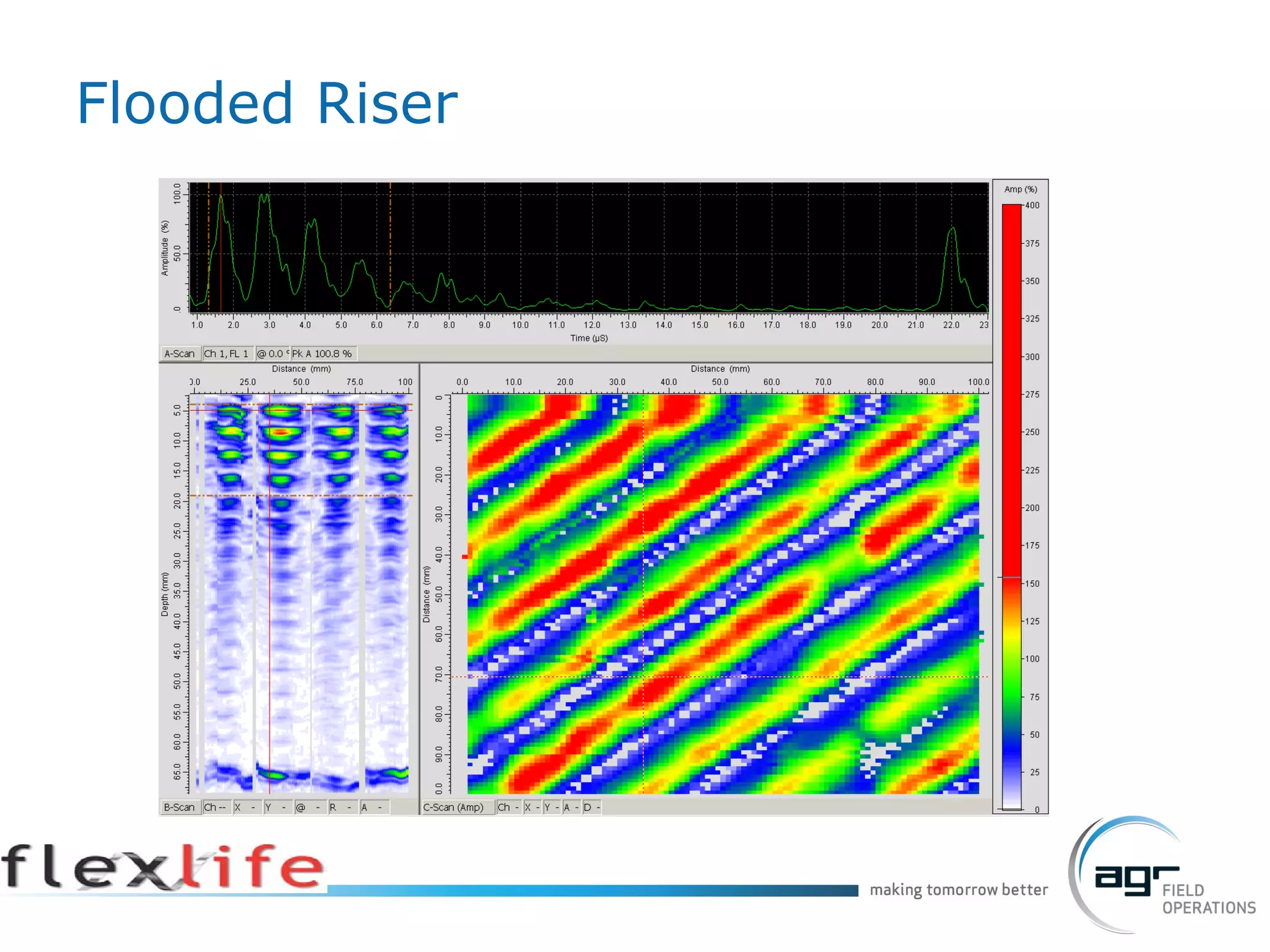

This document discusses AGR's field operations services and technologies for pipeline integrity management and inspection. It provides an overview of AGR's strategy, products and services including internal pipeline inspection tools, laser video inspection, and subsea inspection systems. It also presents case studies on internal pipeline inspections and discusses flexible riser inspection technologies.