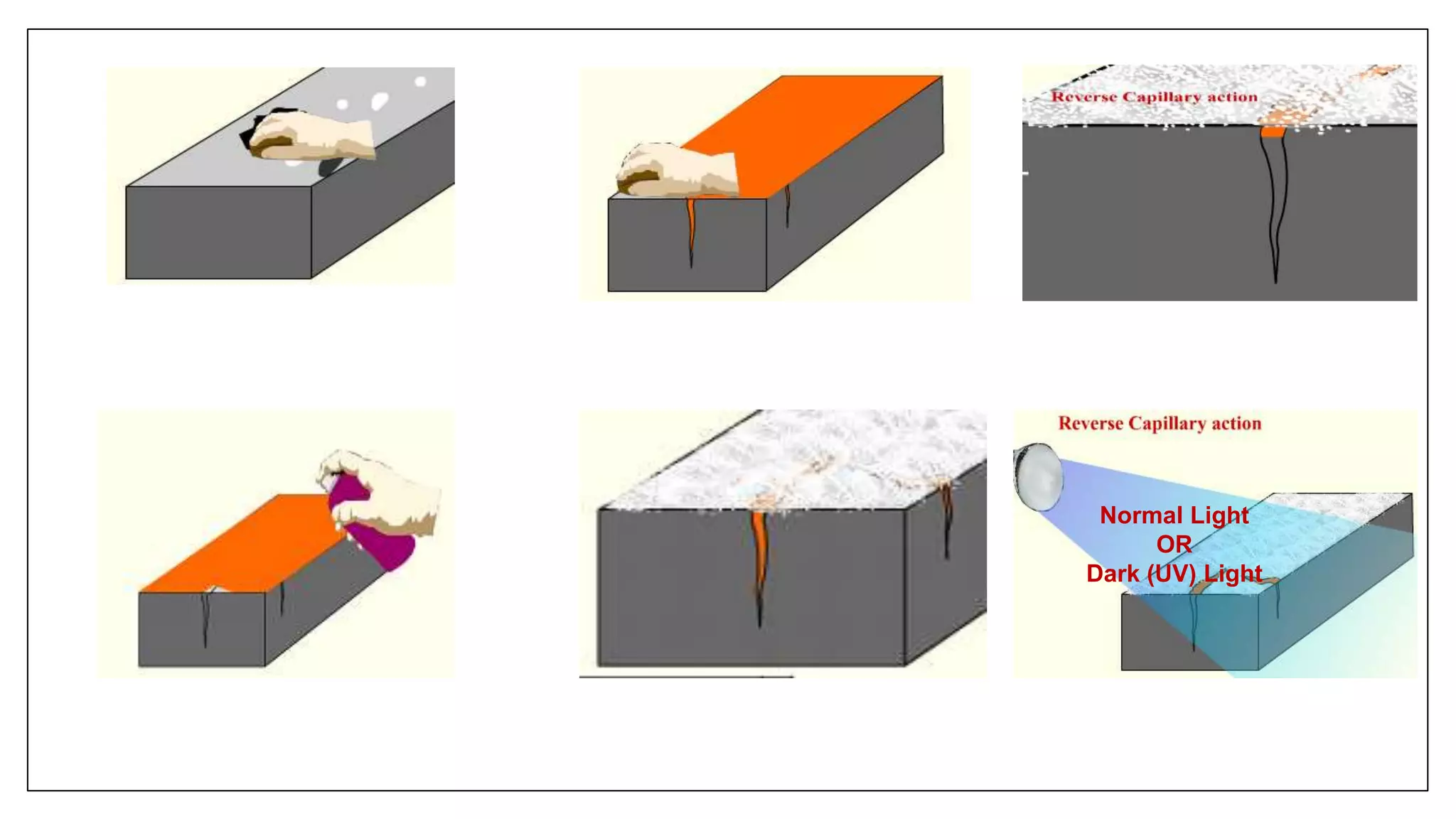

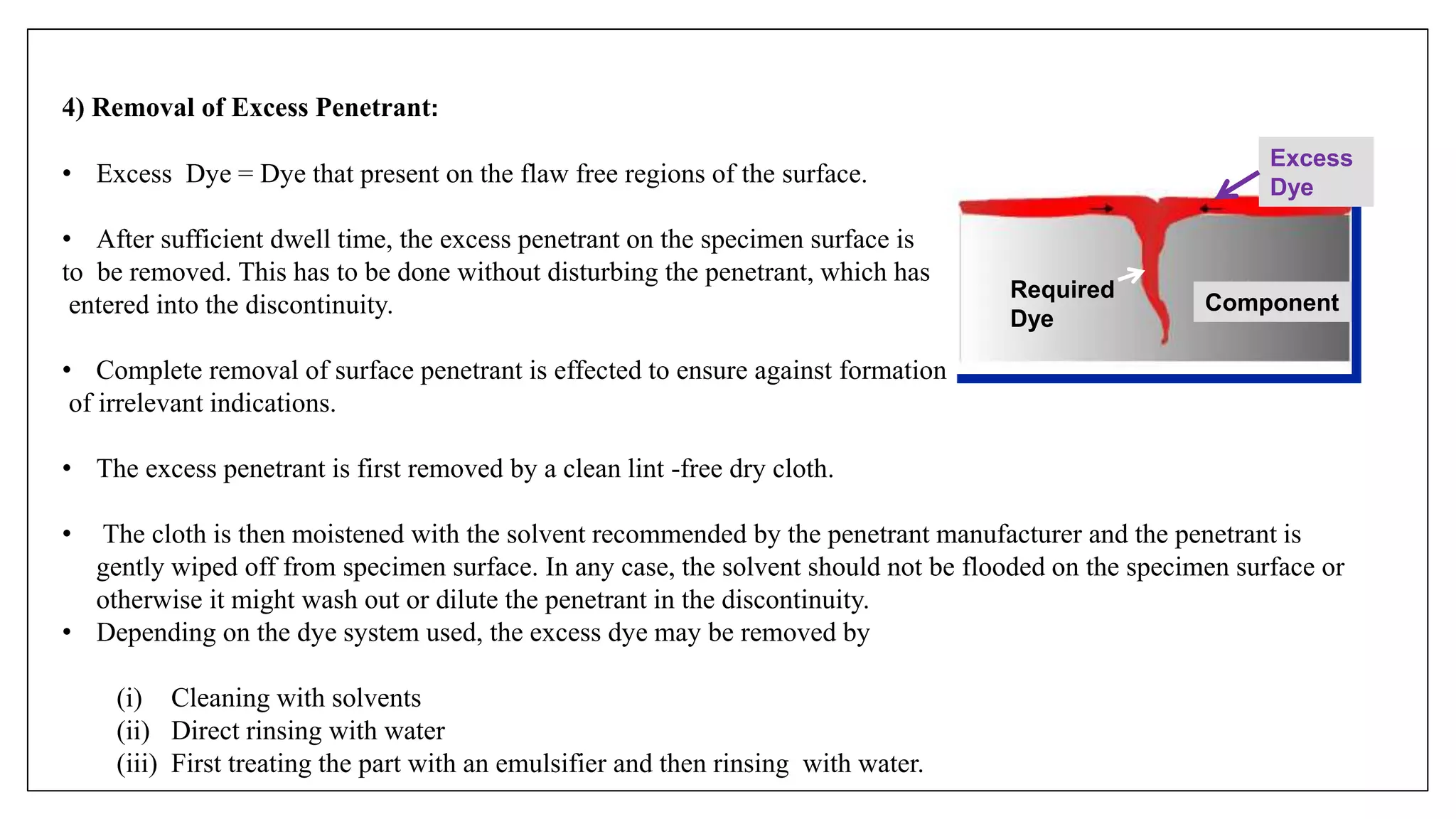

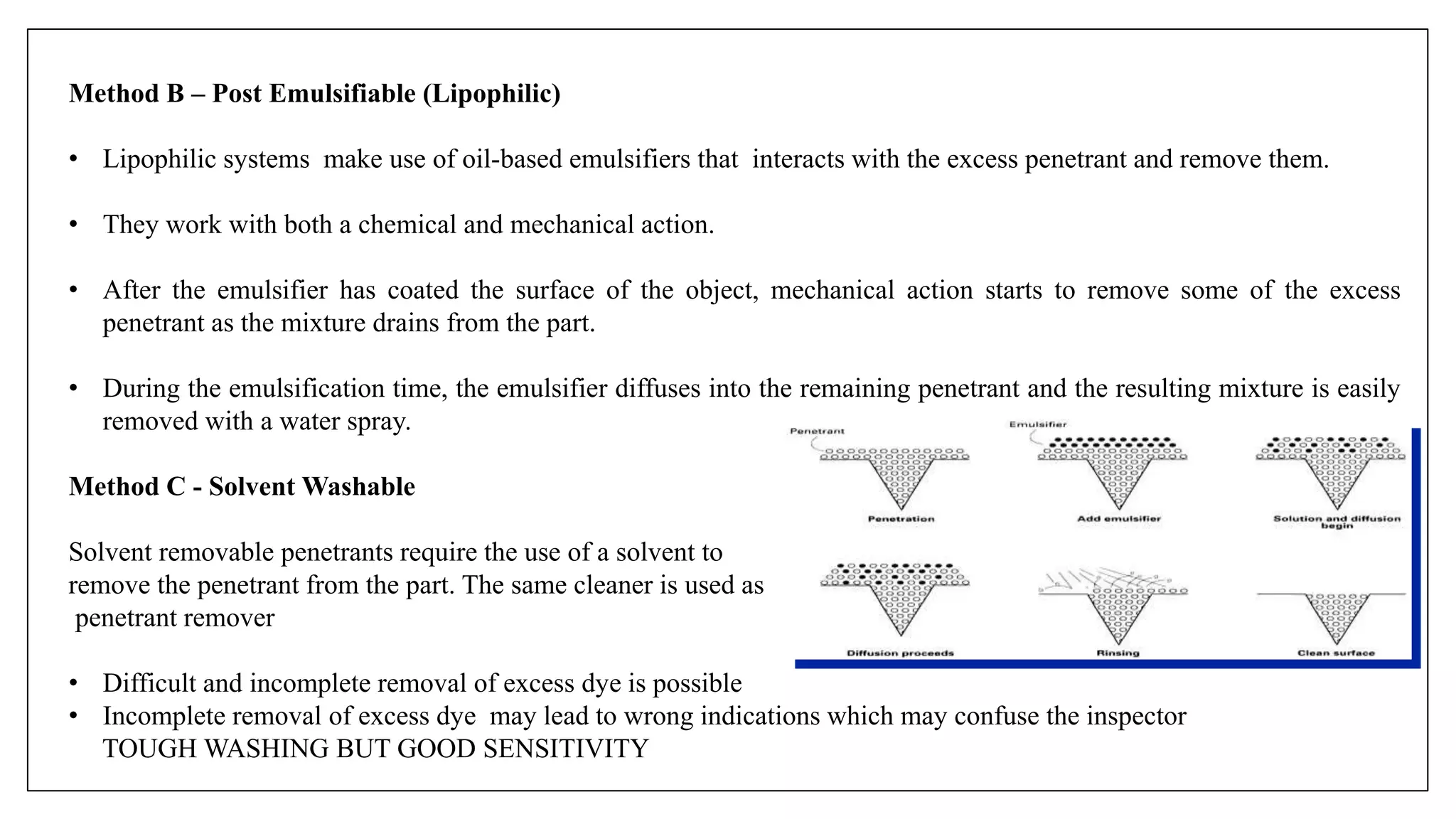

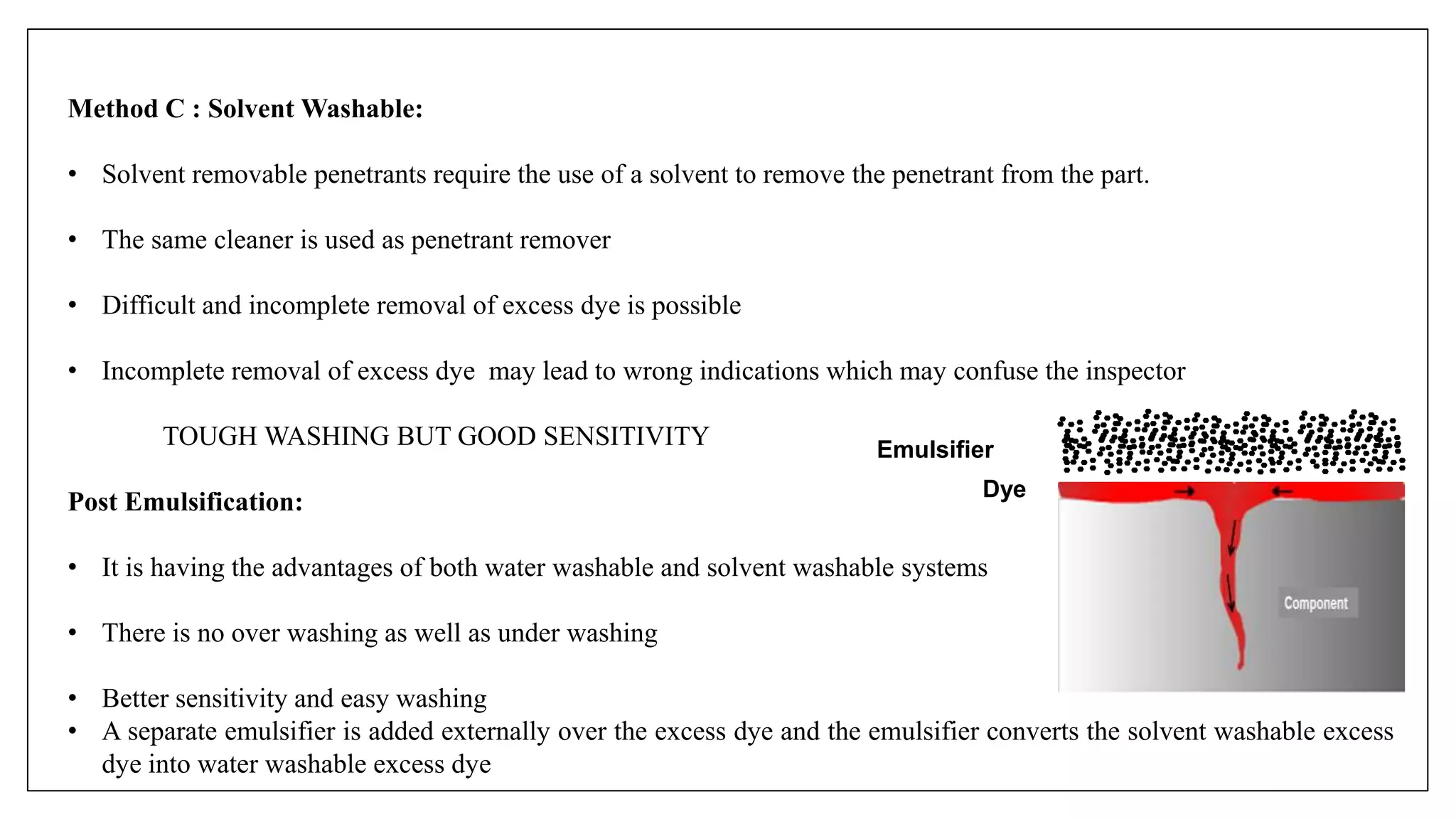

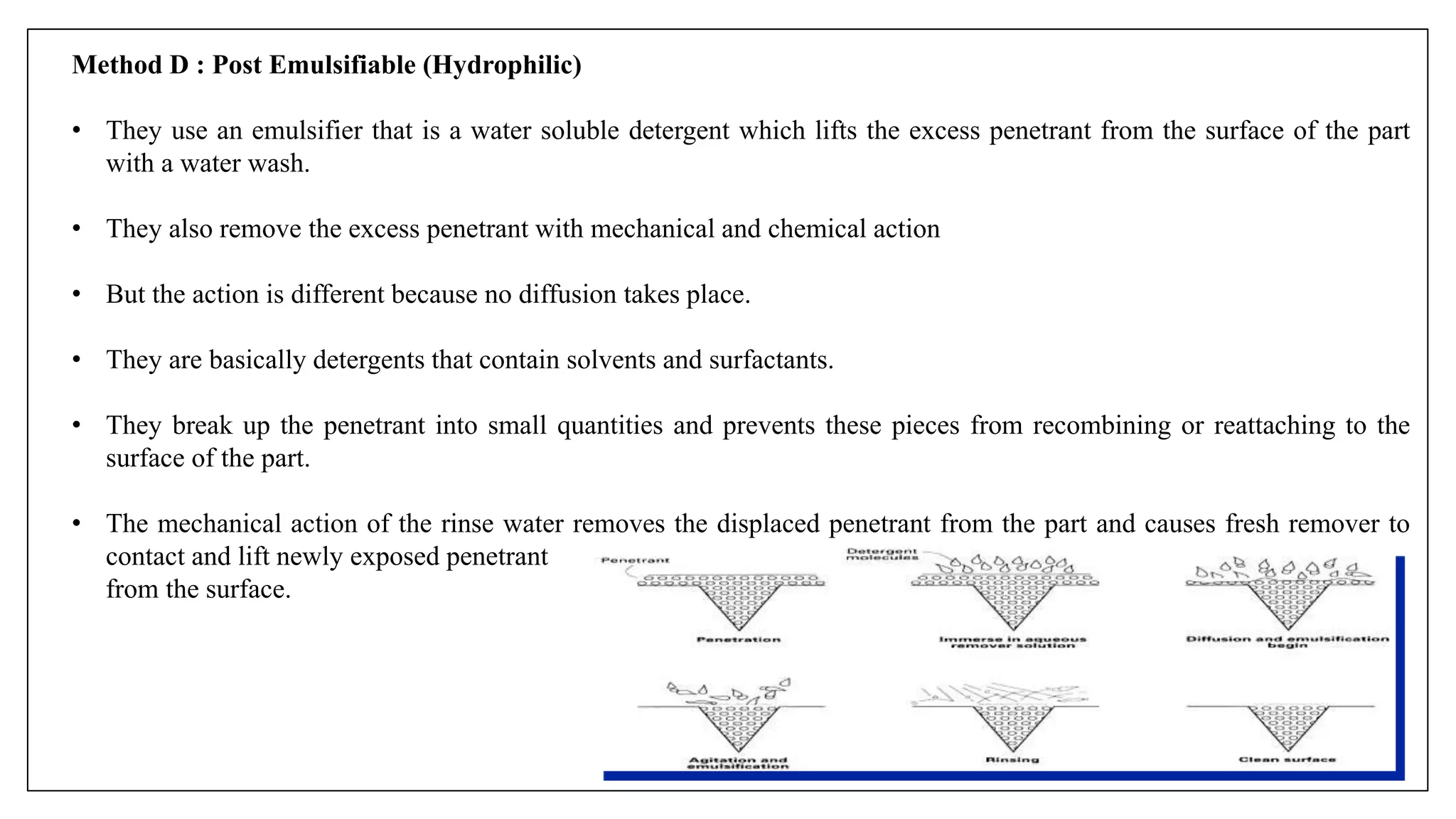

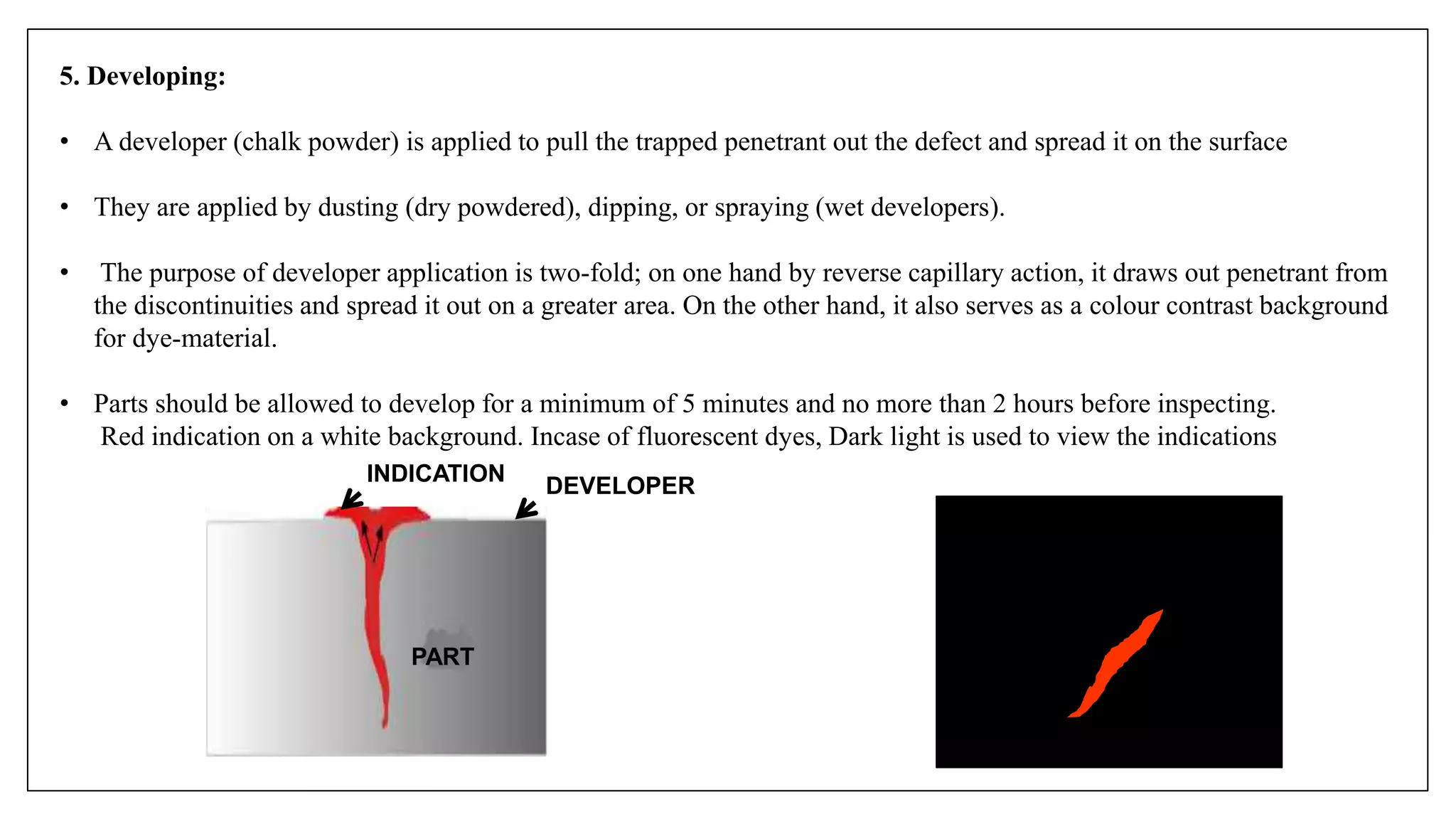

Dye penetrant testing (LPI) is a widely used method for detecting surface discontinuities by applying a liquid dye that seeps into flaws, followed by a developer that extracts the dye for visibility. The process involves several stages, including pre-cleaning, penetrant application, dwell time, removal of excess dye, applying a developer, and interpretation of results, which can be performed under normal or UV light. While effective for surface defects, this method has limitations in detecting subsurface flaws and is heavily dependent on thorough pre-cleaning.