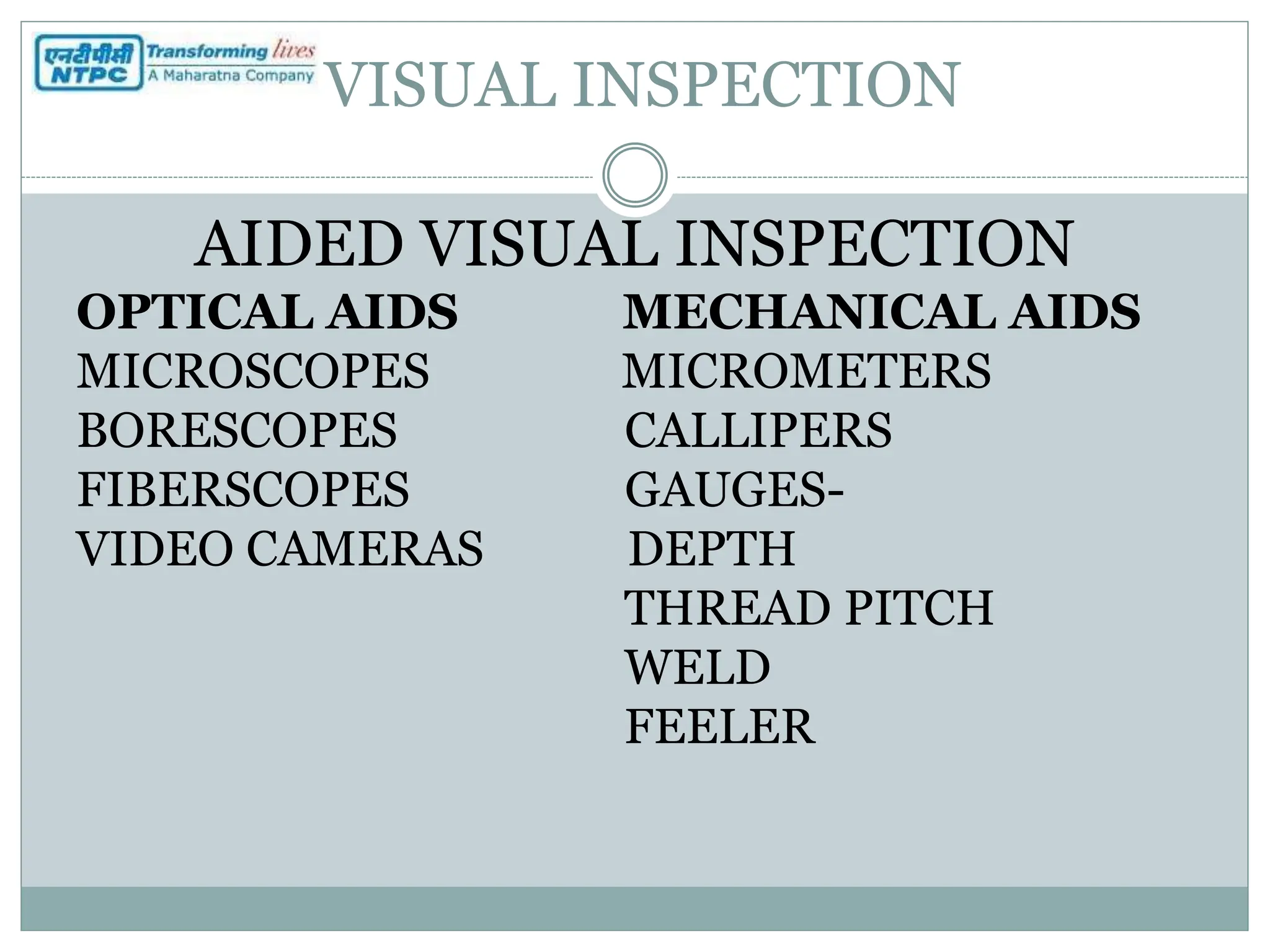

Visual inspection is a fundamental method for examining materials and components for flaws using the naked eye and light, with options for assisted techniques through optical and electronic devices. The effectiveness of visual inspections is influenced by factors such as lighting conditions, the quality of the inspector's detection capabilities, and their training. Machine vision technology has emerged as a valuable tool in automated inspections, particularly in production settings where consistent evaluations are necessary.