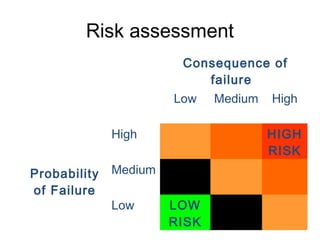

Condition monitoring uses advanced technologies to determine the condition of equipment and predict failures in order to inform predictive maintenance. Techniques include motor current analysis, oil analysis, non-destructive testing, and integrated condition monitoring services which use non-invasive sensing to optimize maintenance. Risk-based inspection decides inspection intervals based on the risk of failure by considering probability and severity, while structural health monitoring monitors infrastructure over time using sensor data to detect damage in structures like bridges, oil rigs, and aircraft wings.