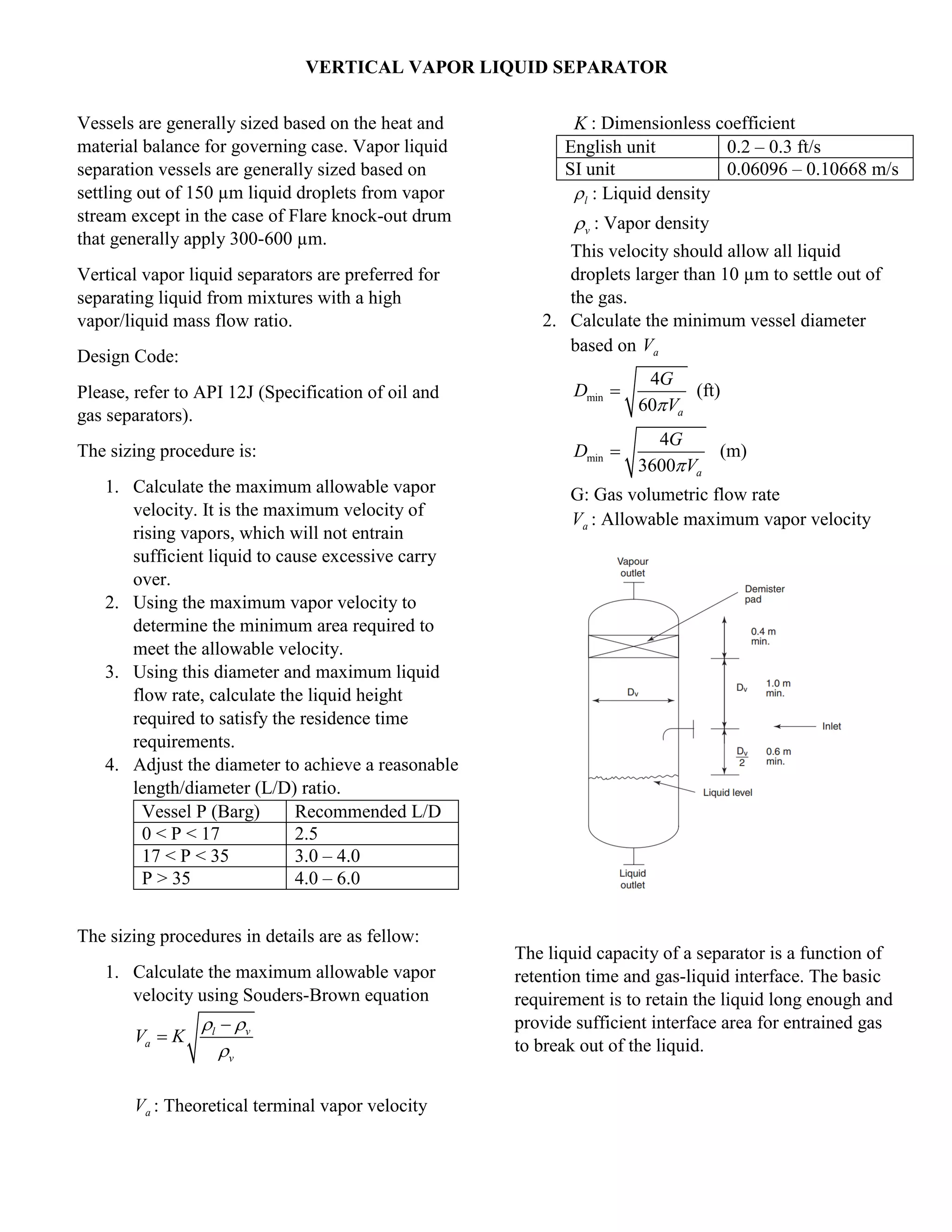

The document outlines the sizing procedures for vertical vapor-liquid separator vessels, emphasizing the importance of calculating maximum allowable vapor velocity and minimum diameter based on specific formulas. It also details retention time and the gas-liquid interface's role in determining liquid capacity, while referring to design codes such as API 12J. Additionally, charts are provided for determining the separator size based on gas capacity requirements.