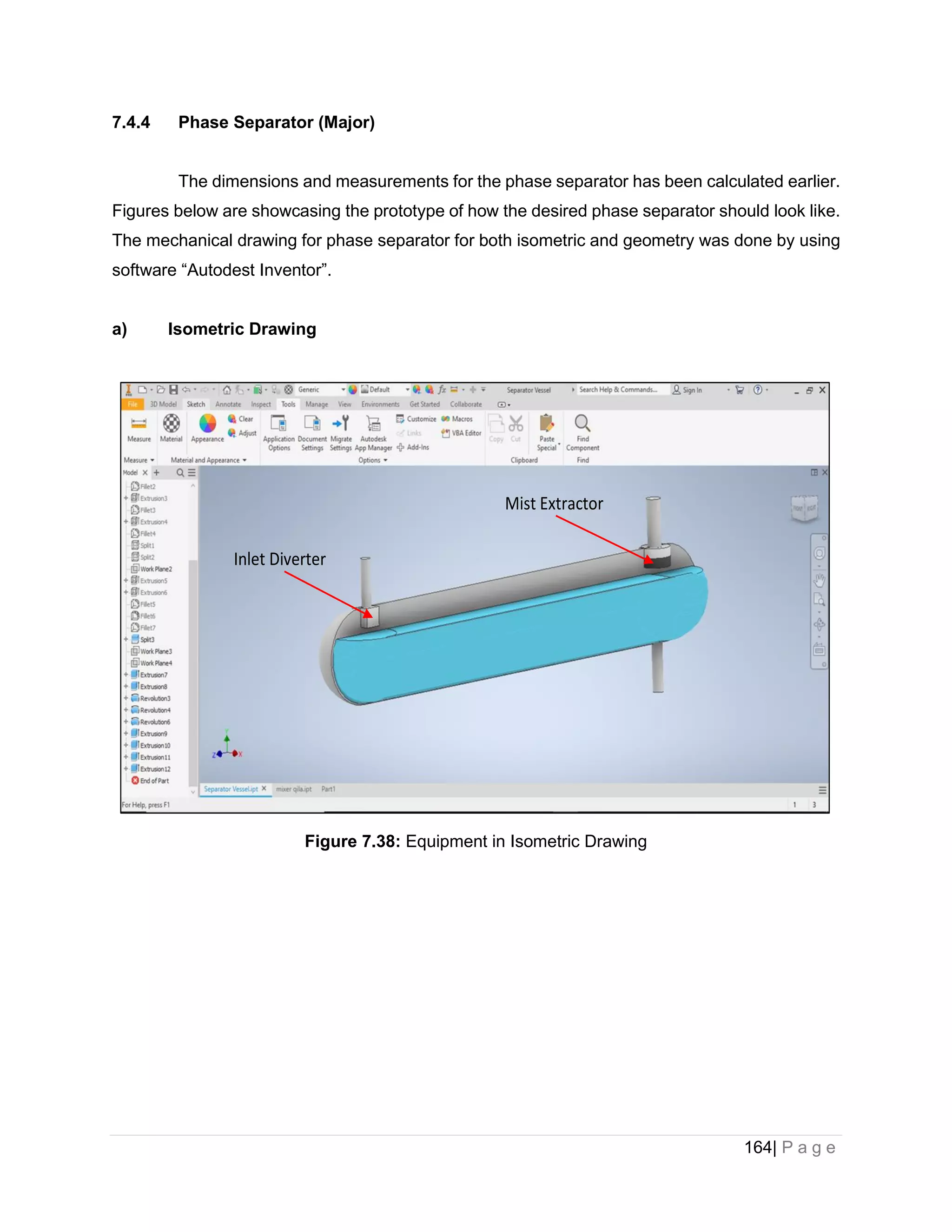

The document describes the design calculations for a phase separator. It includes calculating densities and volumes of incoming streams, sizing the vessel based on volume calculations and pressure ratios, determining liquid level height, and sizing the mist extractor area based on settling velocities and gas flow rates. Dimensional drawings of the horizontal separator vessel are presented, along with specification details like materials of construction, operating conditions, and design parameters.

![147| P a g e

Figure 7.26: Table of length and diameter ratio

When, L = 10 m:

𝐿 = 5𝐷

𝐷 =

𝐿

5

𝐷 = 2 𝑚

Crown radius, Rc:

𝑅𝑐 =

𝐷

2

= 1 𝑚

a) Total Volume of Hemispherical Head

𝑉 =

2

3

𝜋𝑅𝑐3

=

2

3

𝜋(1𝑚)3

= 2.0944 𝑚3

× 2 ℎ𝑒𝑎𝑑𝑠

= 4.1888 𝑚3

b) Volume of Vessel Tank

𝑉 = 𝜋𝑟2

[(

4

3

) (𝑟) + 𝐿]

= 𝜋(1𝑚)2

[(

4

3

)(1𝑚) + 10𝑚]

= 35.6047𝑚3](https://image.slidesharecdn.com/mistextractor-220403112556/75/Mist-Extractor-pdf-3-2048.jpg)