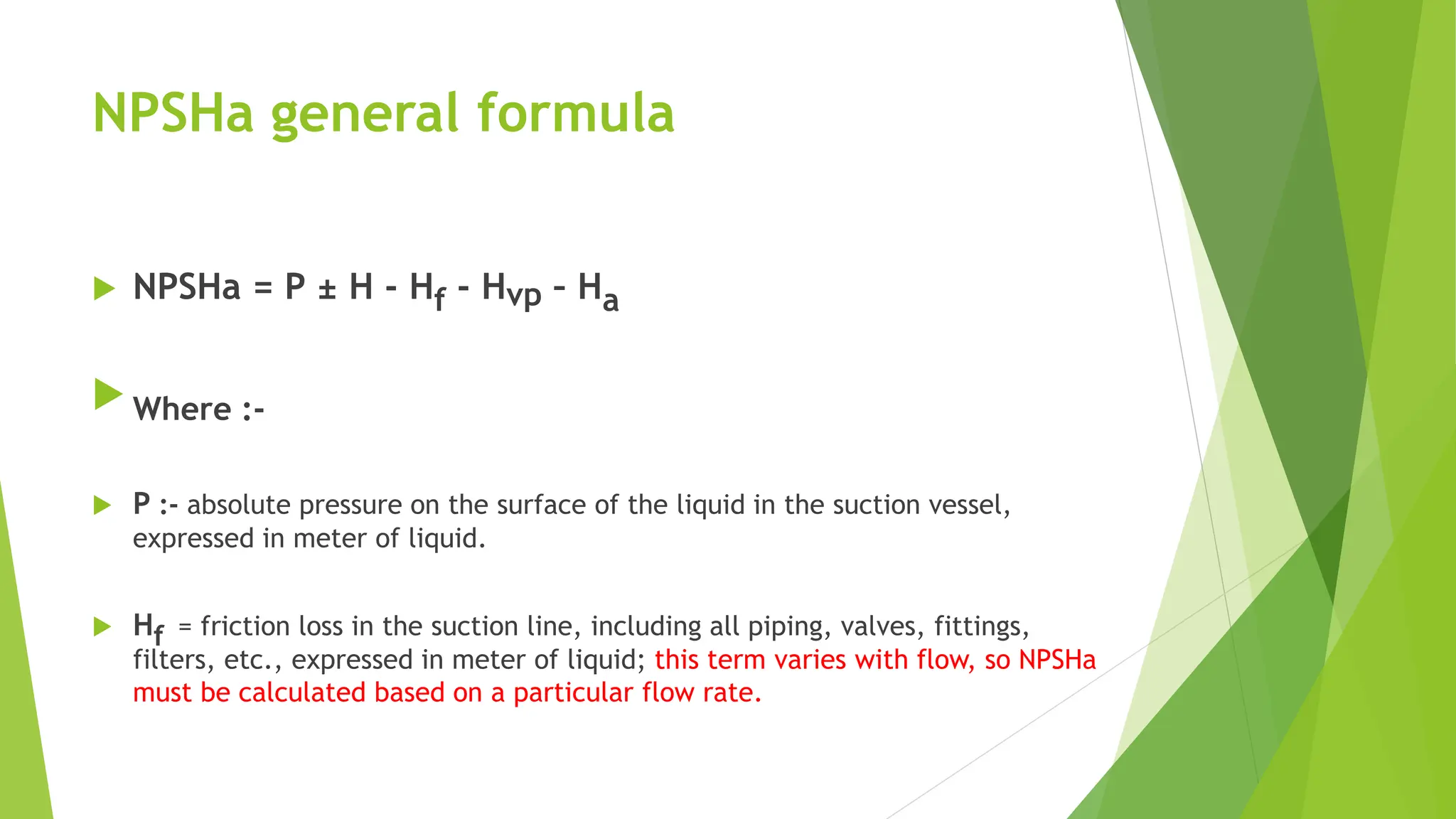

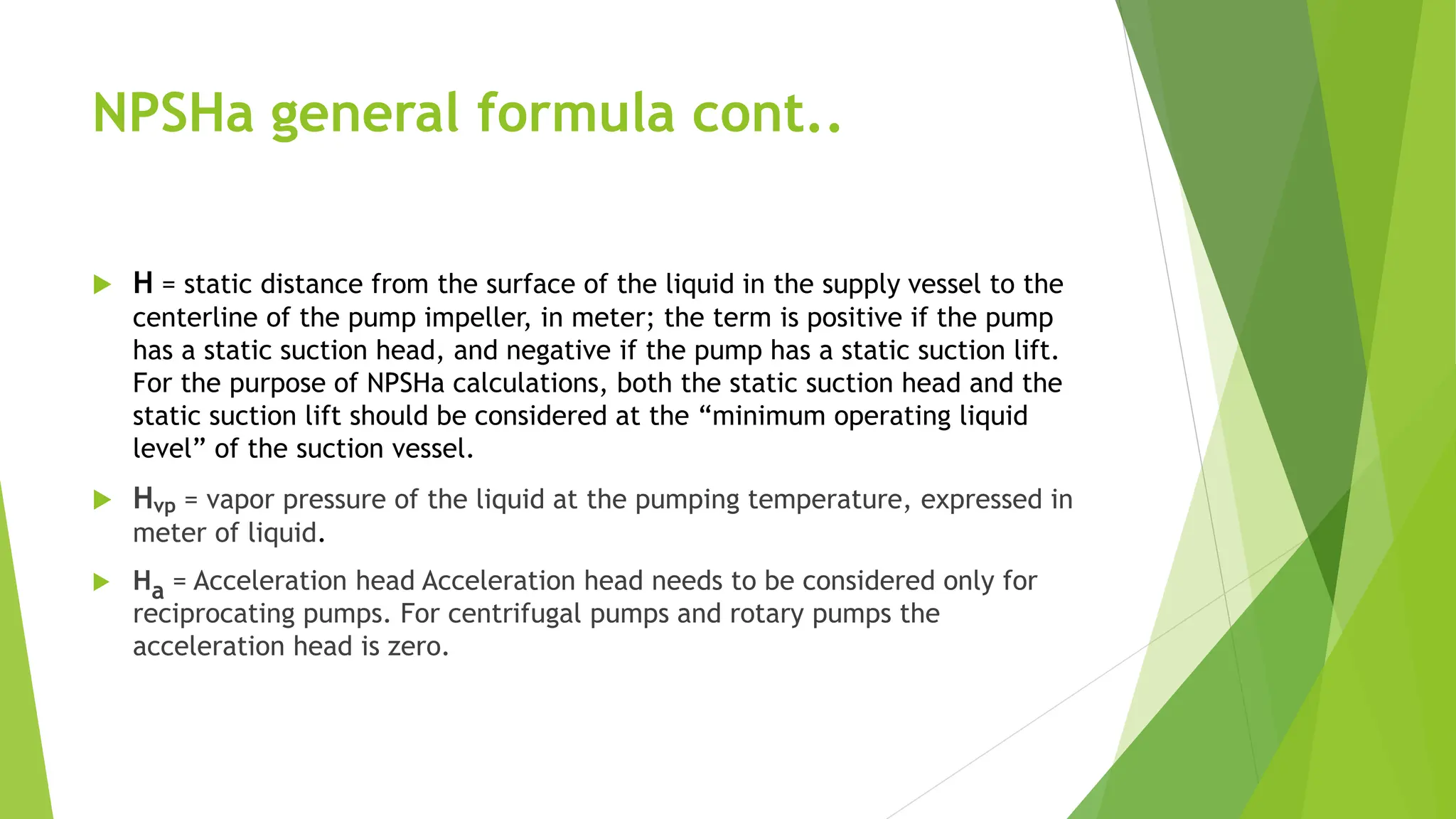

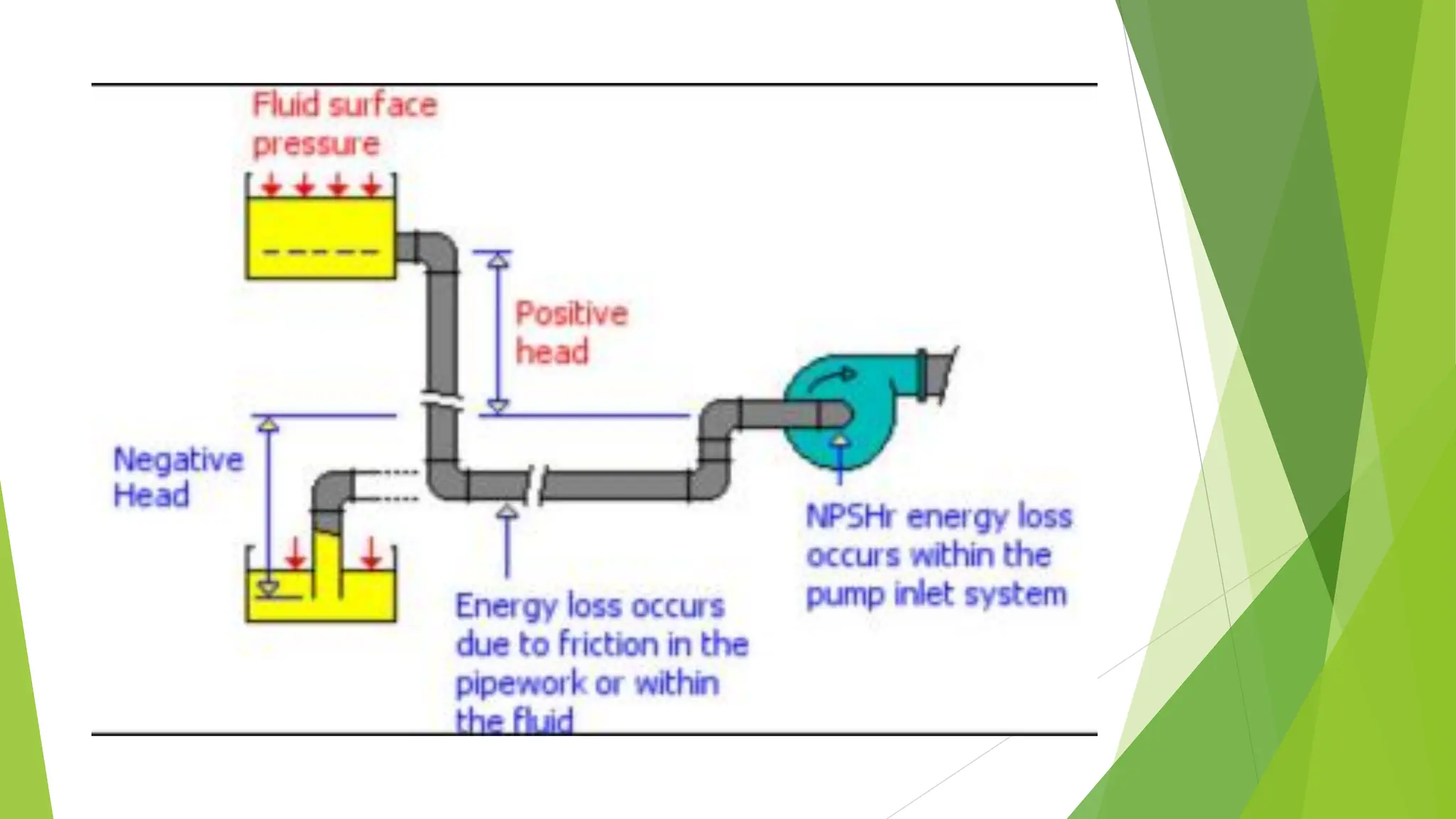

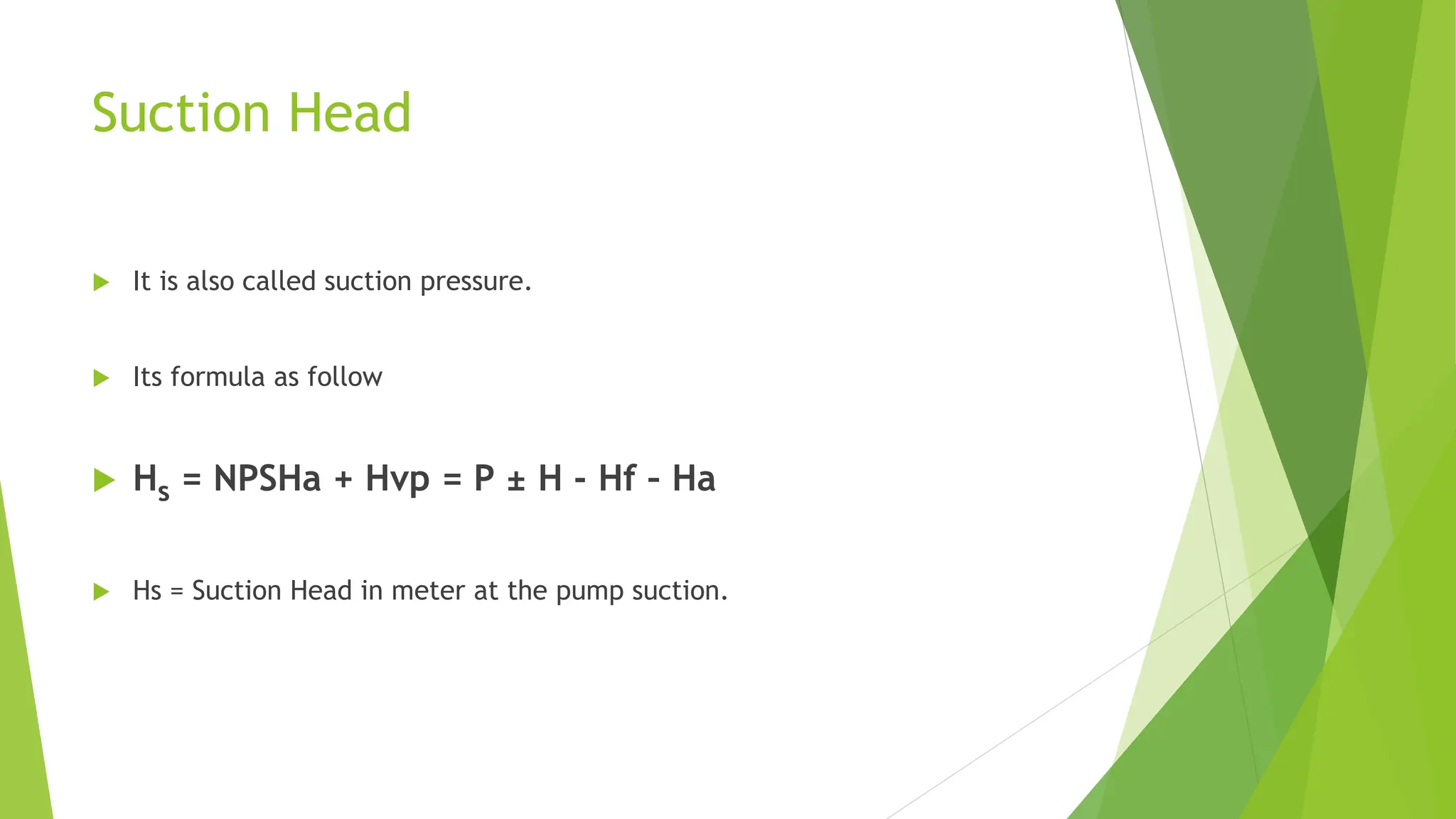

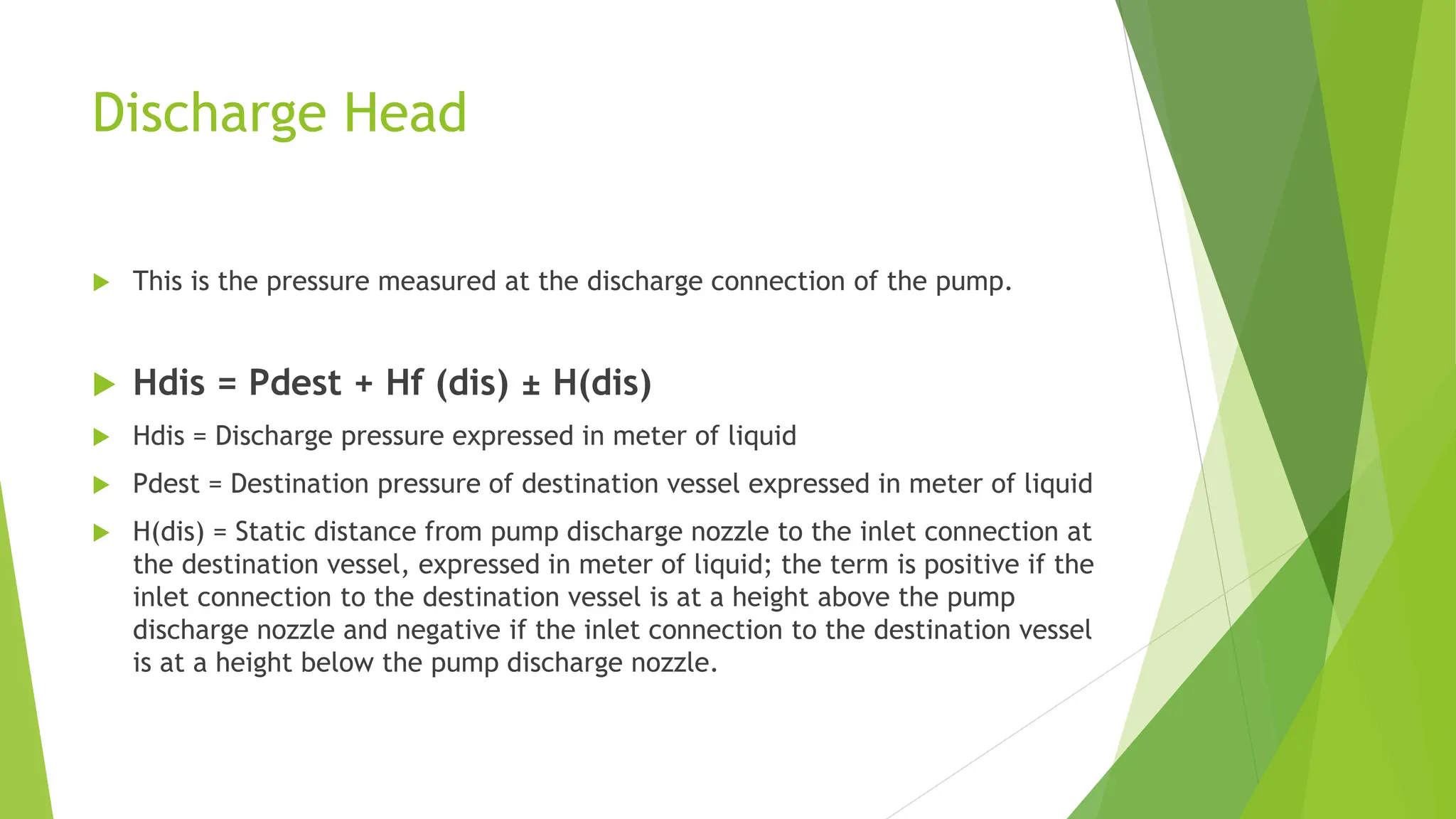

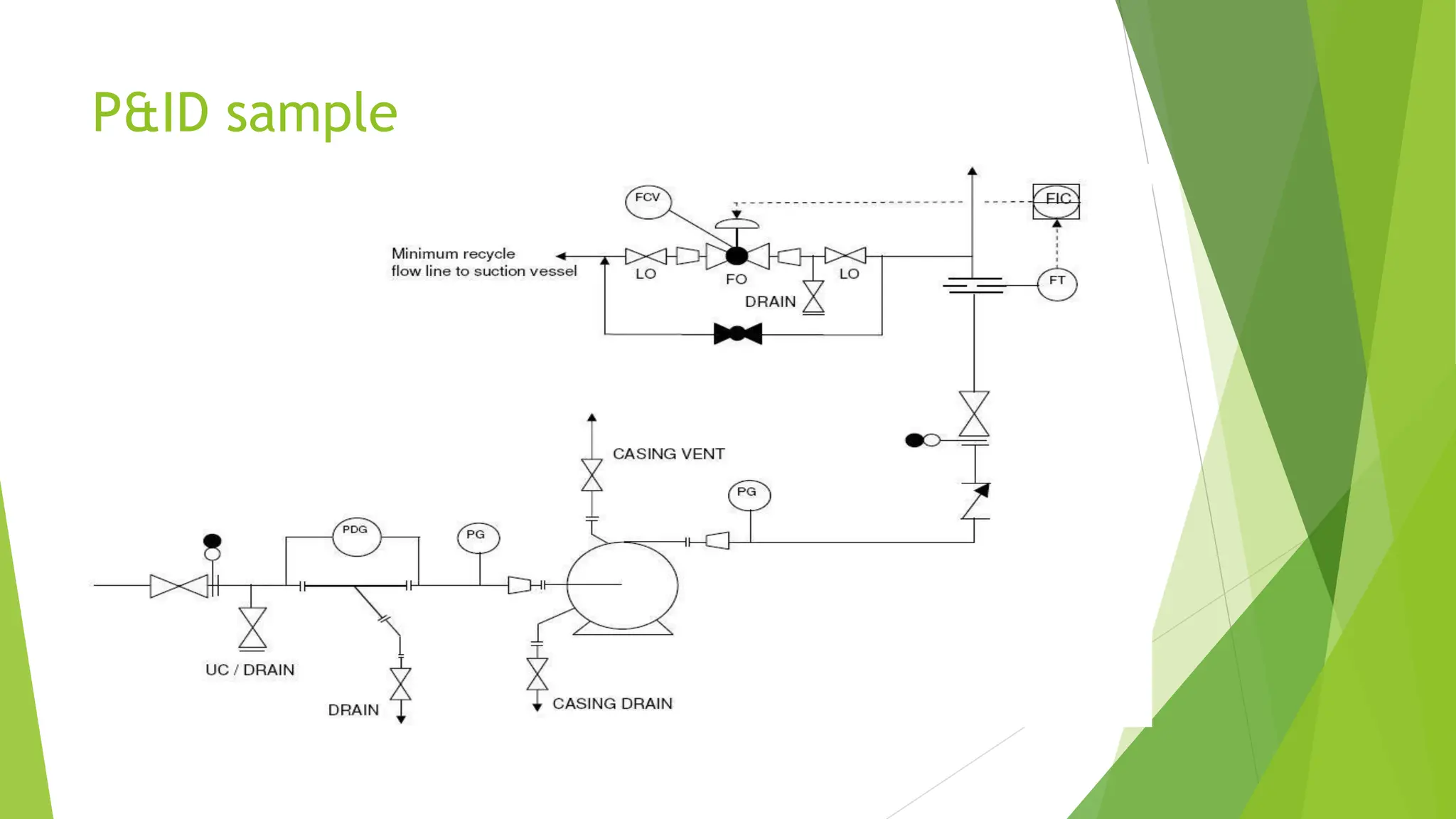

The document discusses hydraulic calculations for pumps including net positive suction head available (NPSHa), suction head, discharge head, differential head, and conversions between head and pressure. It provides formulas for calculating each of these values and discusses API-14E recommendations for suction and discharge piping velocities and sizing. The document contains diagrams of a P&ID and provides a link to a video on simulating pumps in Aspen Plus.