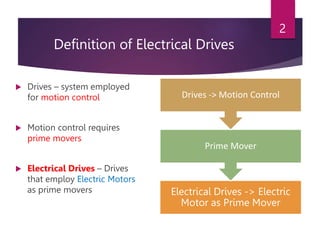

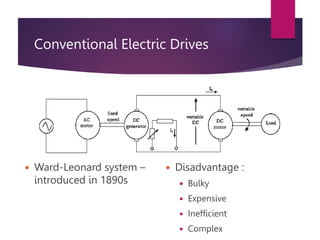

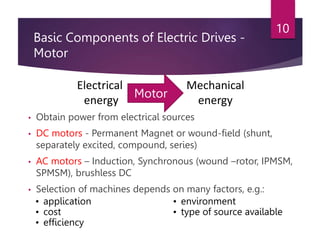

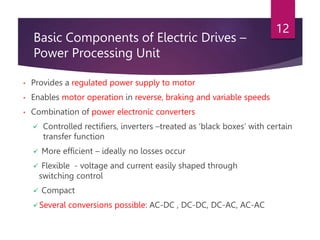

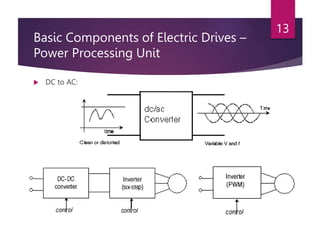

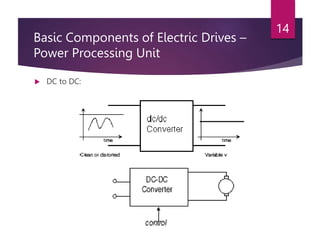

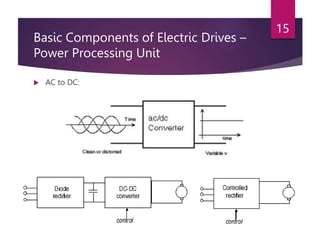

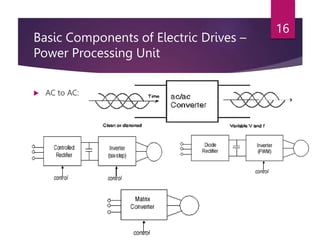

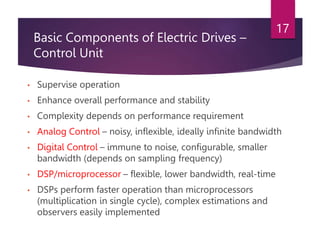

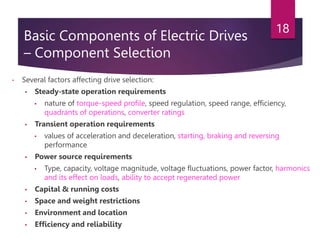

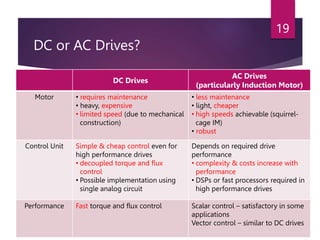

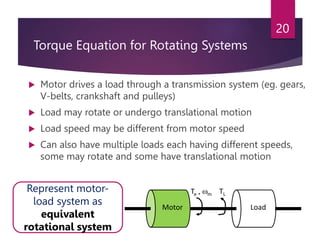

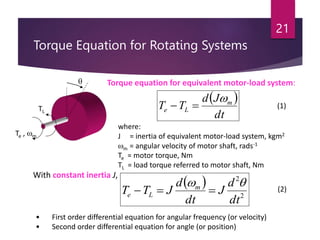

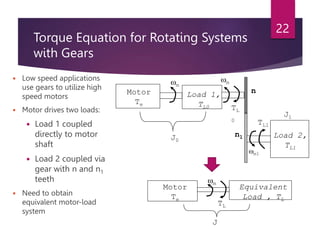

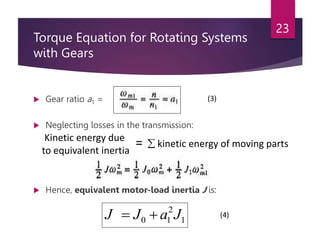

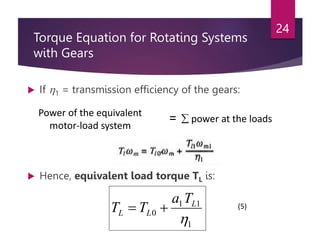

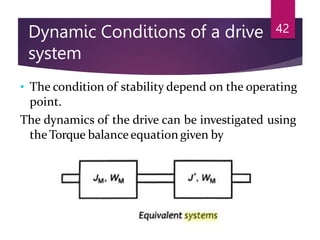

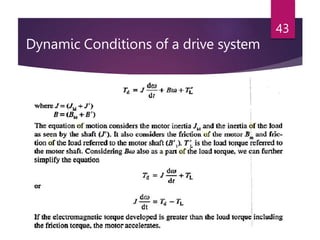

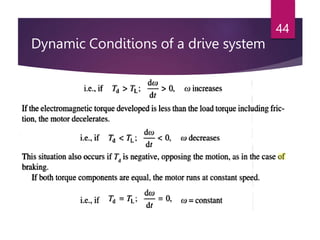

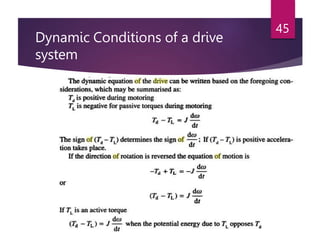

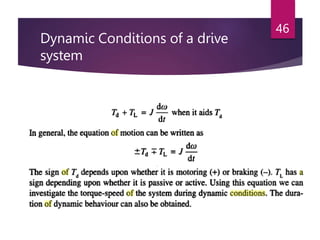

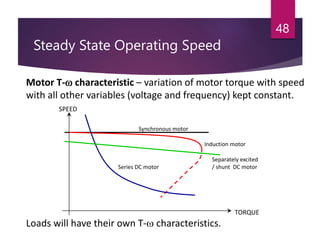

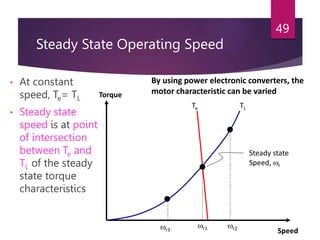

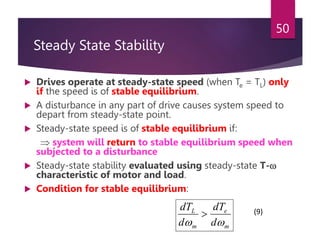

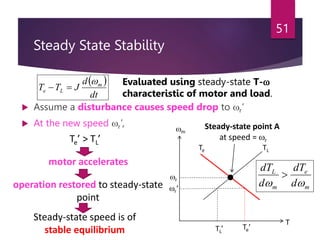

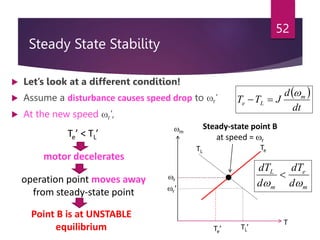

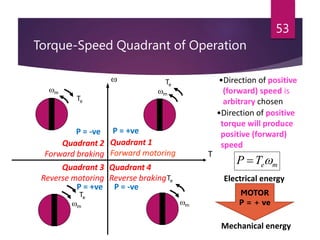

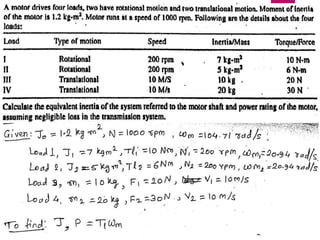

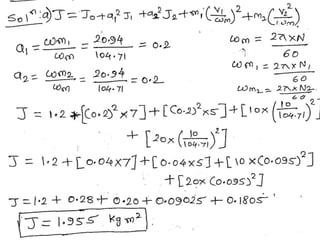

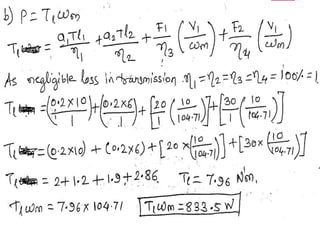

The document discusses electrical drives and their components. An electrical drive uses an electric motor as the prime mover. The basic components of an electrical drive are the power source, motor, power processing unit, control unit, and mechanical load. The power processing unit enables flexible control of the motor speed and torque using power electronic converters. Dynamic conditions in a drive system occur during transients like starting, braking, and speed reversal. Steady-state stability is achieved when the motor torque equals the load torque at a given operating speed.