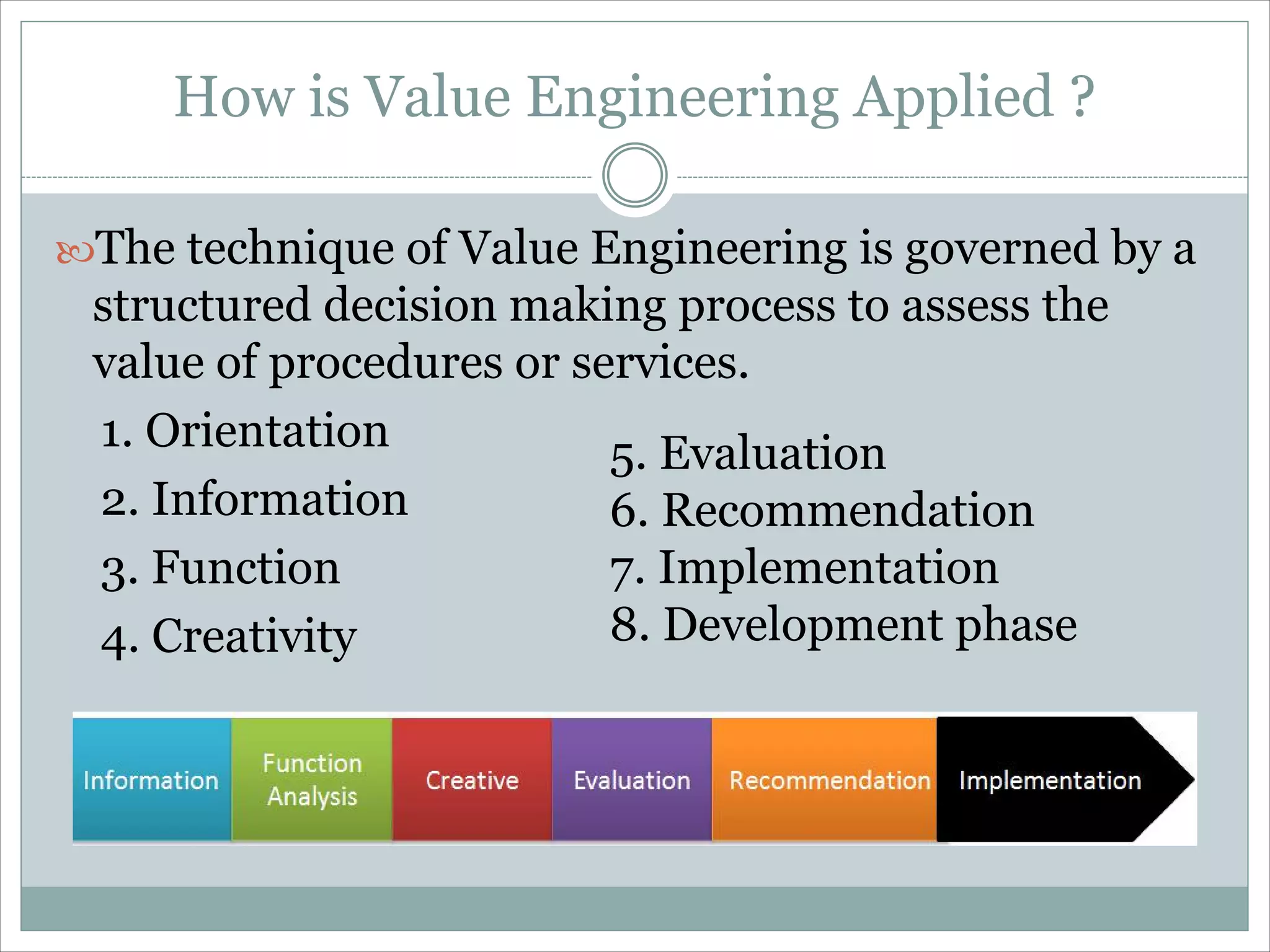

This document provides an overview of value engineering, including its definition, implementation process, benefits, and principles. Value engineering is defined as a systematic team approach focused on providing value in a product, system, or service through cost reduction while maintaining quality and performance. It involves an 8-phase process including orientation, information gathering, functional analysis, creativity, evaluation, recommendation, implementation, and development. The benefits of value engineering include lower costs, improved quality, resource efficiency, and increased competitiveness.